Method for detecting grain storage state

A detection method and state technology, applied in the direction of non-electric variable control, instrument, temperature control, etc., to achieve the effect of efficient ventilation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

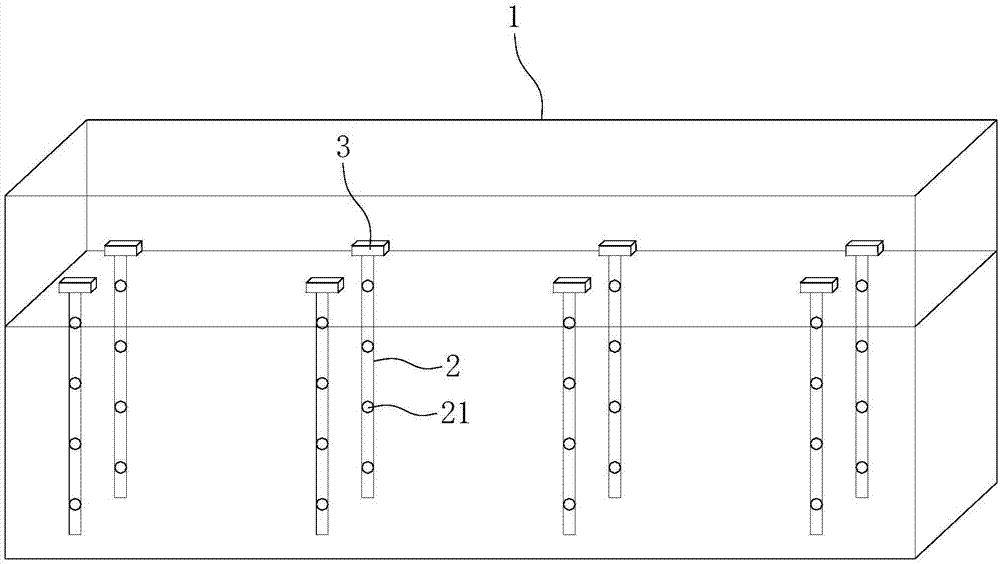

[0046] In this embodiment, a capacitive moisture sensor is placed in the center of the preset space, and the capacitance of the grain in the preset space is measured by the capacitive moisture sensor, and the abnormal increase, significant increase, and significant increase of the grain moisture measured by the capacitive moisture sensor To characterize the abnormal increase, obvious increase, and significant increase of grain capacitance. In this way, it is easy to read and judge.

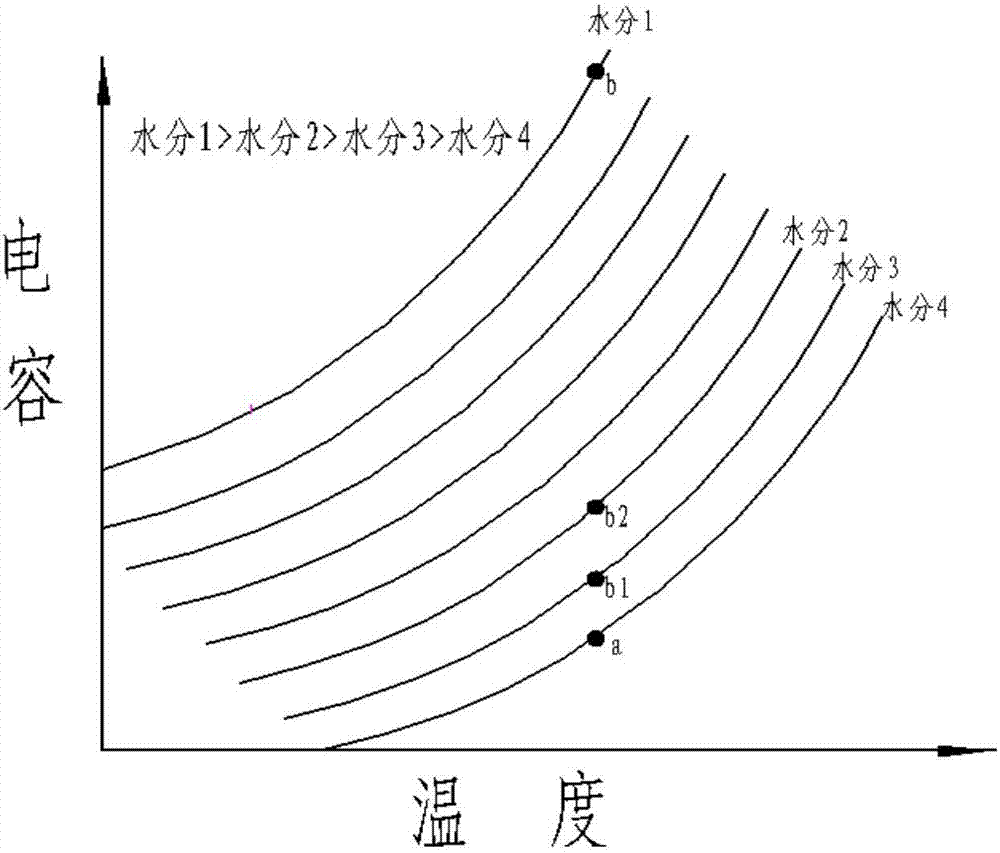

[0047] The capacitive moisture sensor is essentially a capacitor, and its electric field lines cover a certain space around the sensor (that is, the preset space). Therefore, the measured grain capacitance in the preset space can also represent the grain dielectric constant in the preset space. see figure 2 , the grain moisture is constant, the grain dielectric constant increases with the increase of grain temperature; the grain temperature is constant, the grain dielectric constant increases w...

Embodiment 2

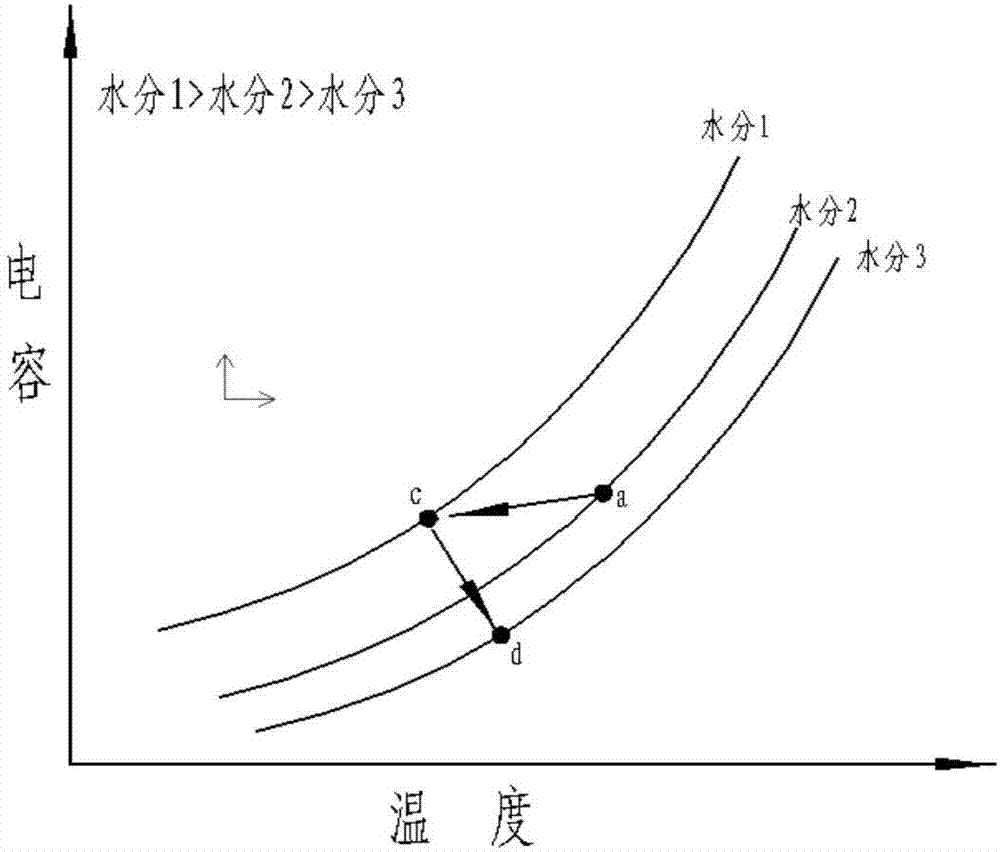

[0067] Mechanical ventilation to reduce grain temperature

[0068] like image 3 As shown, it is point a (moisture value is 14%) before ventilation, and after a period of ventilation, the outside of the grain has cooled but the internal temperature has not completely dropped, and it becomes point c (that is, the internal temperature of the grain is higher than that of the grain). The external temperature and the temperature sensor temperature drop slowly, so the internal dielectric constant decreases slowly. But the moisture measurement value is calculated according to the sensor temperature and internal dielectric constant, so the moisture measurement value will increase and the sensor temperature will decrease; the moisture value is 15.5 %); after the internal temperature of the grain drops, the inside and outside of the grain and the temperature sensor reach thermal equilibrium again, point c will eventually become point d (moisture value is 13.5%), that is, grain moisture ...

Embodiment 3

[0071] Conditioner ventilation for added moisture

[0072] like Figure 4 As shown, at the beginning of the ventilation, the water is concentrated on the surface and outside of the grain, and the capacitance of the capacitive moisture sensor increases. The resulting capacitance will gradually decrease. In this process, the moisture measurement value will increase obviously from the initial value point a (moisture value 13%) to point e (moisture value 16%), and then gradually decrease and approach the true moisture value after adding water. Value f point (moisture value 14.5%).

[0073] Conclusion: According to this method, it can quickly and intuitively reflect that the moisture value measured by the capacitive moisture sensor increases significantly due to the water on the surface of the grain during the conditioning and ventilation process of the grain, while the internal moisture of the grain changes slowly. When the moisture value measured by the capacitive moisture sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com