Layered in-situ loess collapsibility coefficient testing device and method

An in-situ testing and testing device technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc. Avoid disturbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

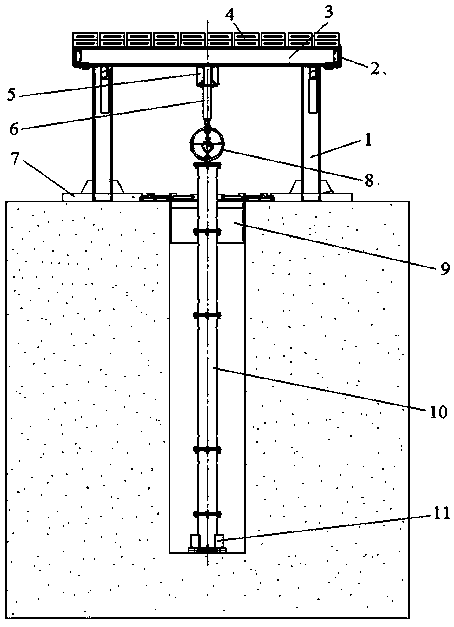

[0029] Such as figure 1 As shown, the test device of the present invention includes a force measuring ring 8, a centering mechanism 9, a force transmission mechanism 10, a pressure bearing mechanism 11 and a support; the support includes a base 7, and four legs 1 are vertically fixed on the base 7. , the four outriggers 1 form a rectangle and are fixedly connected to the base 7, and the top ends of the four outriggers 1 are fixedly connected with a reaction mechanism, which includes a plurality of main beams 3 arranged side by side, and a plurality of main beams The two ends of 3 are fixedly connected with two side beams 2 arranged side by side respectively, the reaction force mechanism is fixedly connected with four support beams 1 through two connecting beams, and the top ends of the two support beams 1 are connected through a connecting beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com