Method for recovering metals from secondary materials and other materials comprising organic constituents

A technology of secondary raw materials and recycling methods, applied in the field of metal recycling, which can solve the problems of high cost cleaning steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

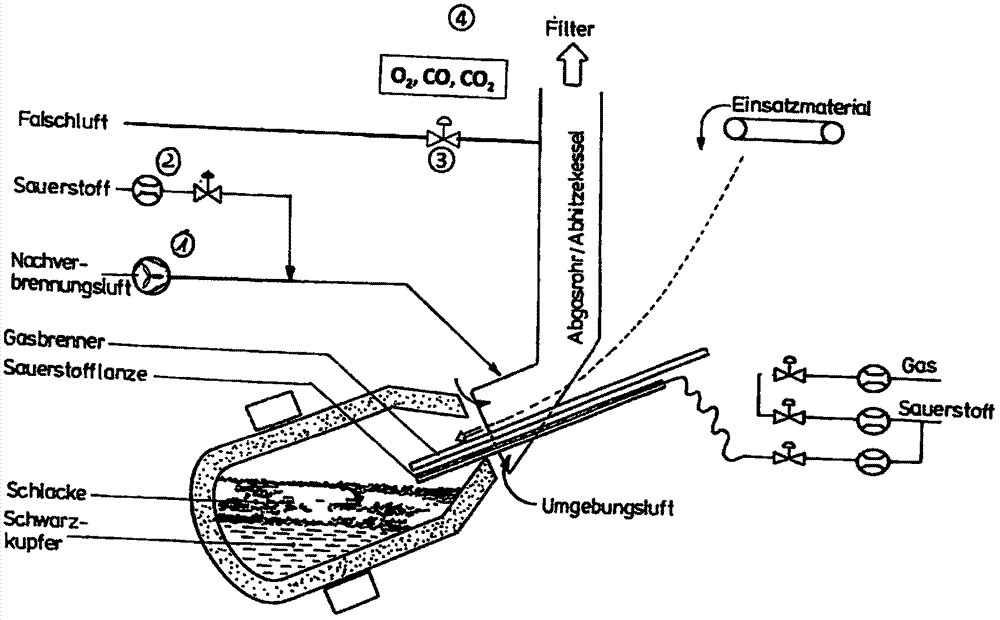

Image

Examples

Embodiment Construction

[0018] Complex secondary raw materials with organic proportions are, in addition to sampling for classical property measurements, also checked with regard to their energy content and proportion of slag formers in order to obtain information for guiding the production process. For the production capacity achievable for secondary raw materials with an organic proportion, the energy content and thus the amount of metal recovery are important. In striving to achieve low viscosity and precious metal content, relevant slagging substances (Fe / FeO, SiO 2 、Al 2 o 3 , CaO, Na 2 O, K 2 O, Mn, Cr) information is important for guiding slagging.

[0019] Among these raw materials, Al 2 o 3 , SiO 2 and the same oxidation to Al which always contains 2 o 3 The high content of refractory components in the form of metallic aluminum leads to a high-melting, high-viscosity residue during such a melting process, which in particular prevents the obtaining of a residue with a low noble metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com