Roller-sweeping operation device of snow remover

The technology of a working device and a snow removal vehicle is applied in the fields of snow surface cleaning, construction, cleaning methods, etc., which can solve the problem of not being able to adjust separately, and achieve the effect of ensuring the snow removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the embodiments described here are only used to explain the present invention, but not to limit the present invention.

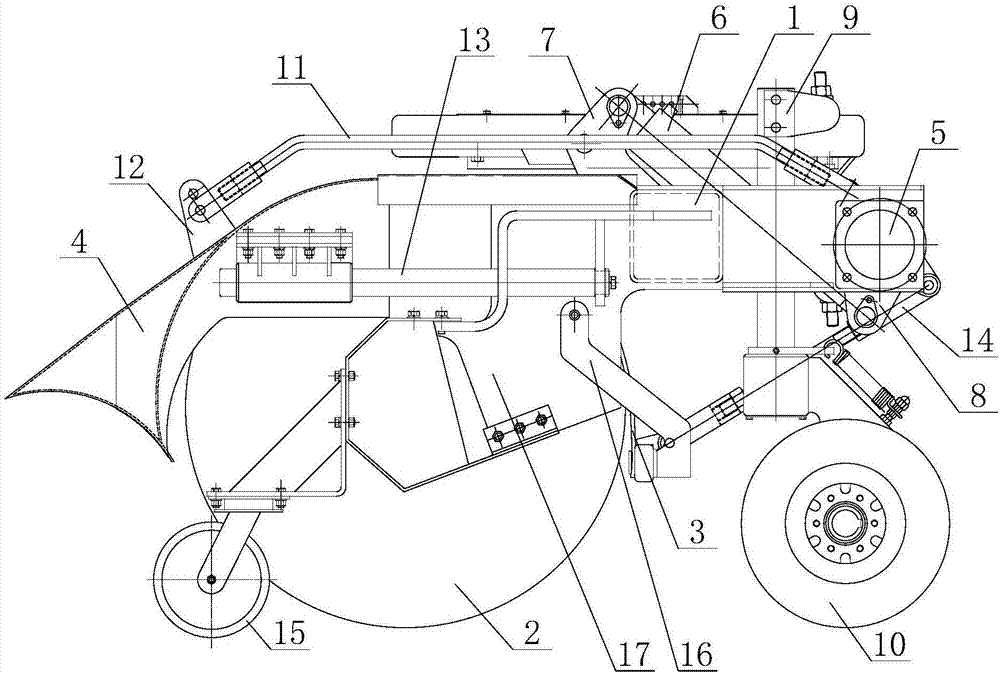

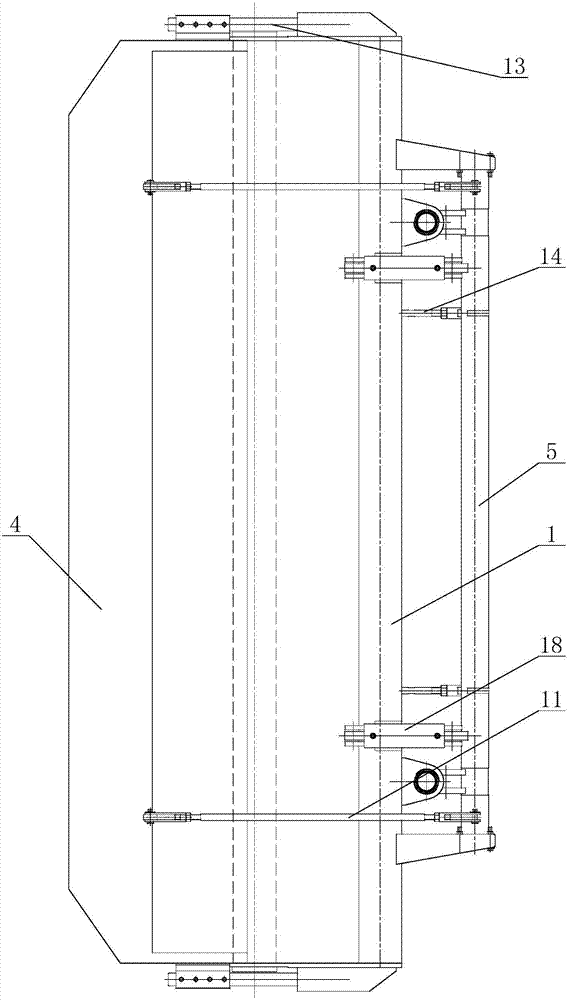

[0018] Please refer to figure 1 and figure 2 as shown, figure 1 It is a front view of a roller sweeping operation device of a snow removal vehicle of the present invention; figure 2 It is a top view of a roller sweeping operation device of a snow removal vehicle according to the present invention.

[0019] In this embodiment, a roller sweeping operation device for a snow removal vehicle includes a beam 1, a lifting cylinder for adjusting the overall ground pressure, a roller sweep assembly 2 installed at the front end of the beam 1, and a roller sweep assembly 2 located at the rear of the roller sweep assembly 2. The rear baffle 3, the front cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com