Input device

An input device and input operation technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of complex structure and large number of components, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, an input device according to an embodiment of the present invention will be described with reference to the drawings.

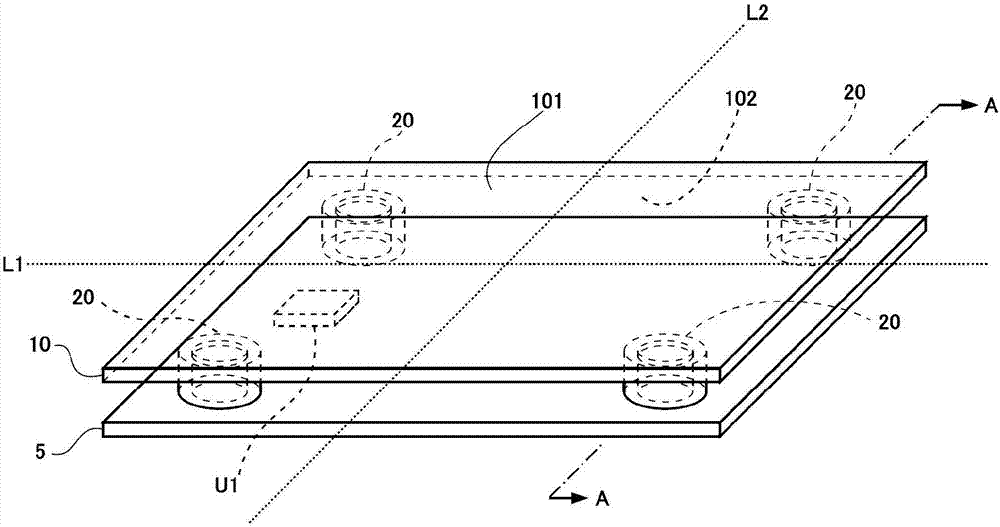

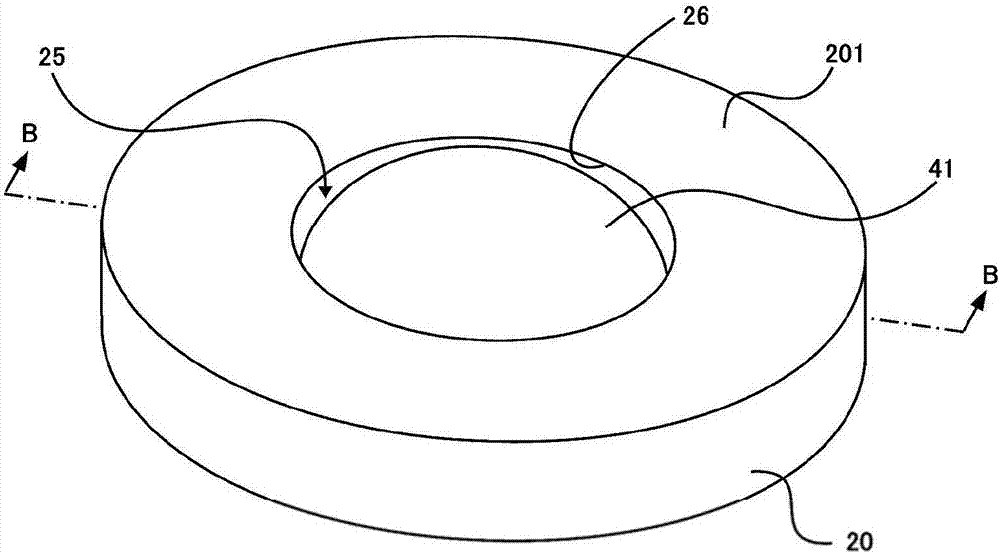

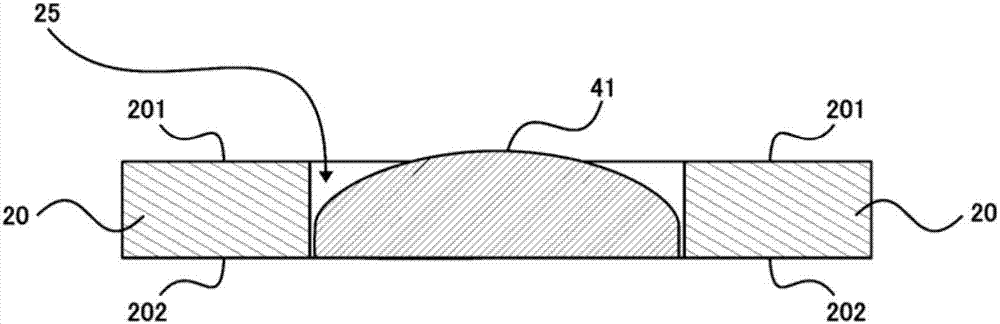

[0041] figure 1 It is a figure which shows an example of the structure of the input device of this embodiment. figure 1 The shown input device has a substrate 10 for receiving input operations and four support portions 20 elastically supporting the substrate 10 , and inputs information corresponding to various input operations performed by touching the substrate 10 with a finger, a pen, or the like. This input device has a function of detecting a force applied to the substrate 10 and a function of detecting the position of an object approaching the substrate 10 as a detection function for inputting information corresponding to an input operation.

[0042] Substrate 10 in figure 1 In the example shown in FIG. The substrate 10 accepts input operations on the first surface 101 . In addition, in figure 1 In the example shown above, the pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap