Switch core part structure capable of preventing action dead point

A technology of switch core and dead point, applied in the direction of electric switches, electrical components, emergency springs, etc., can solve problems such as wrong action, flickering, and machine damage of machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

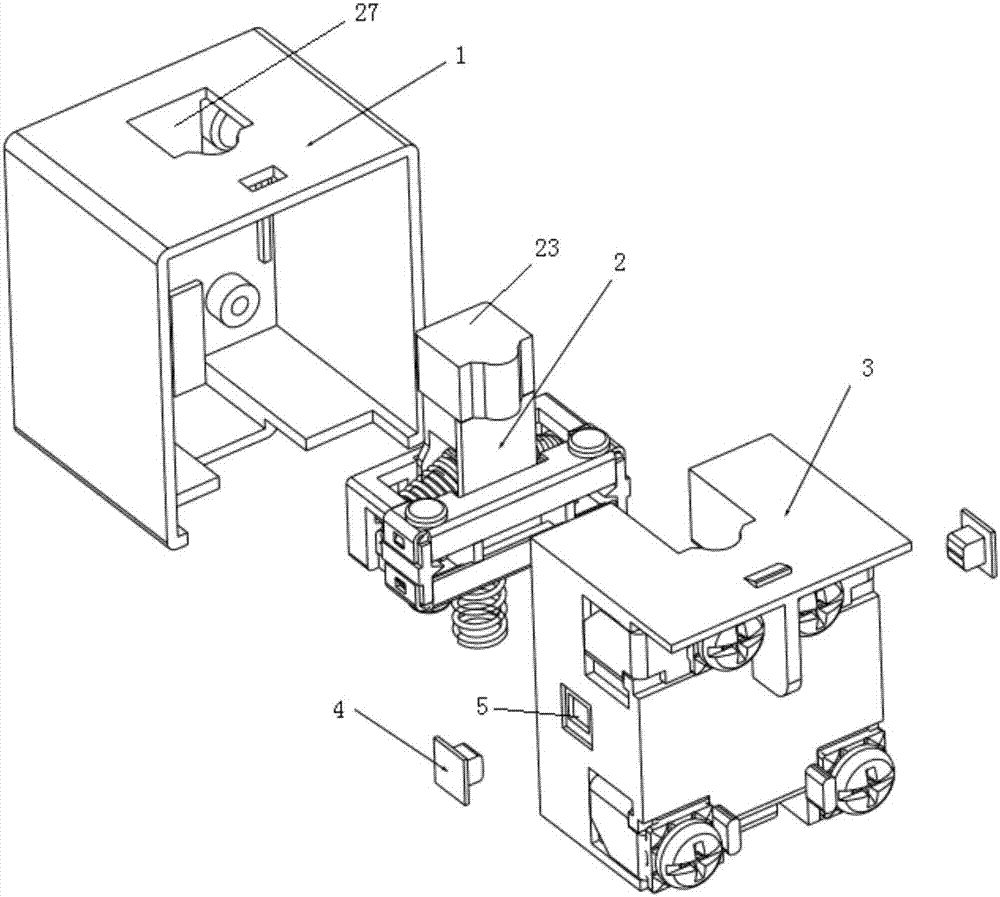

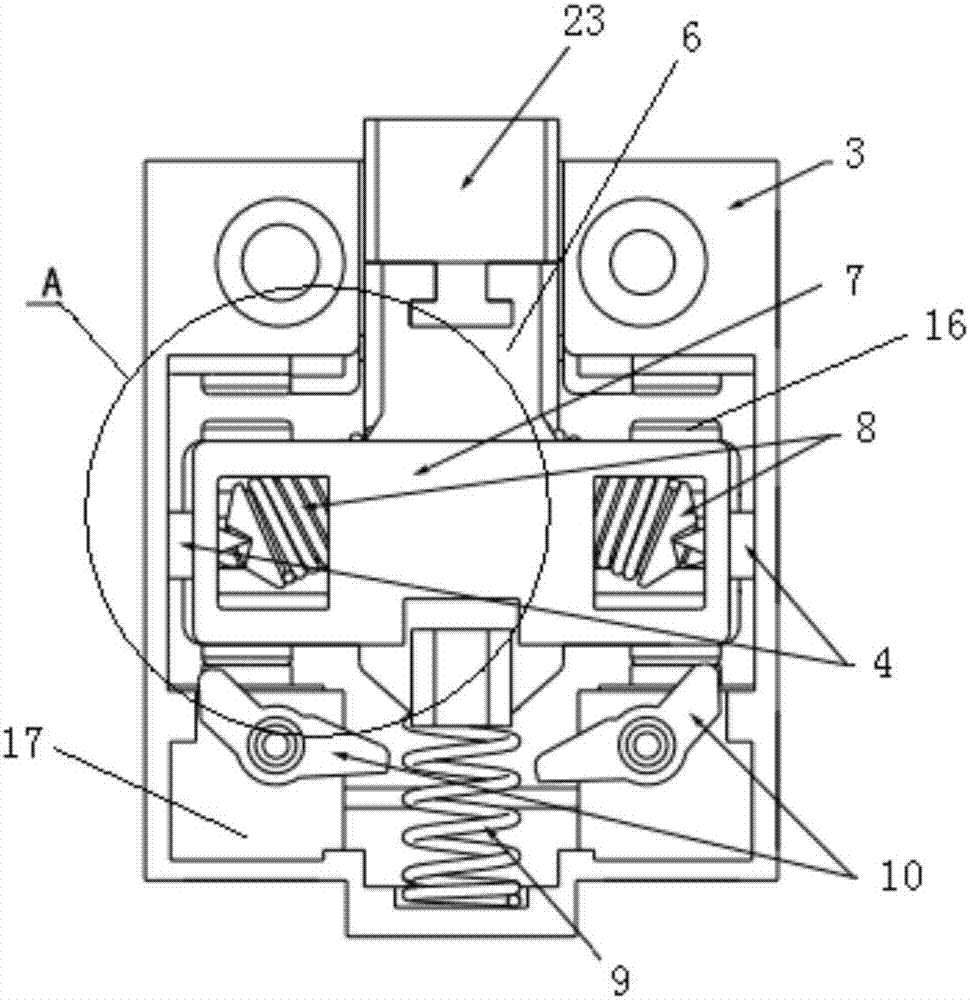

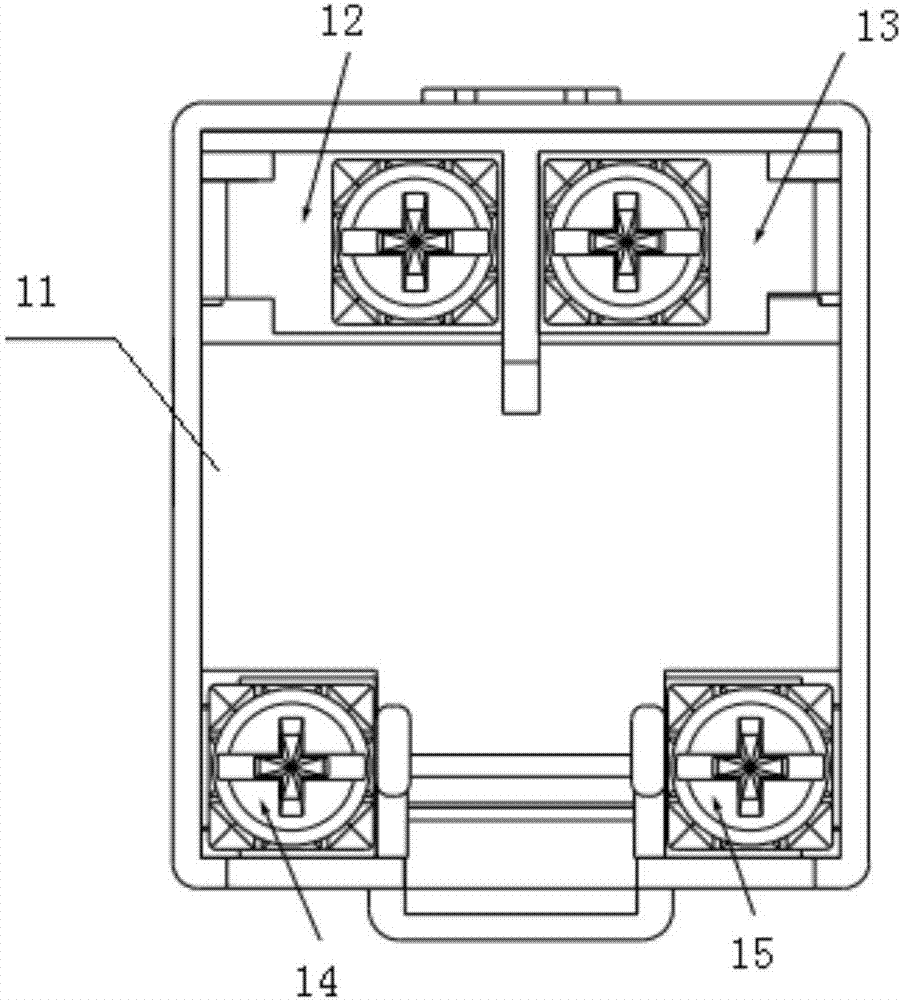

[0031] like figure 1As shown, a switch core structure to prevent action dead point includes a base 1, a base assembly 3 and a movable assembly 2, the base assembly 3 and the base 1 are rectangular cover structures, the base assembly 3 and the base 1. The opening surface is relatively socketed, and the base 1 is socketed on the periphery of the base assembly 3; the movable assembly 2 is arranged between the base 1 and the base assembly 3, and the top surface of the base 1 is provided with a hole 27; the base assembly 3 It includes a lower cover 11, a left normally open socket assembly 12, a right normally open socket assembly 13, a left normally closed socket assembly 14 and a right normally closed socket assembly 15. The two sides of the lower cover 11 are respectively provided with corresponding rectangular Holes 5 and rectangular holes 5 are inlaid with positioning blocks 4, and the opposite faces of the two positioning blocks 4 are slope structures with a high middle and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com