Electric hoists used for transfer of machinery and equipment in the manufacturing scheduling process of the workshop

A technology for dispatching process and mechanical equipment, applied in the direction of portable hoisting device, hoisting device, etc., can solve the problems of electric hoist overload, electric hoist power failure, etc., to reduce danger, avoid safety accidents, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

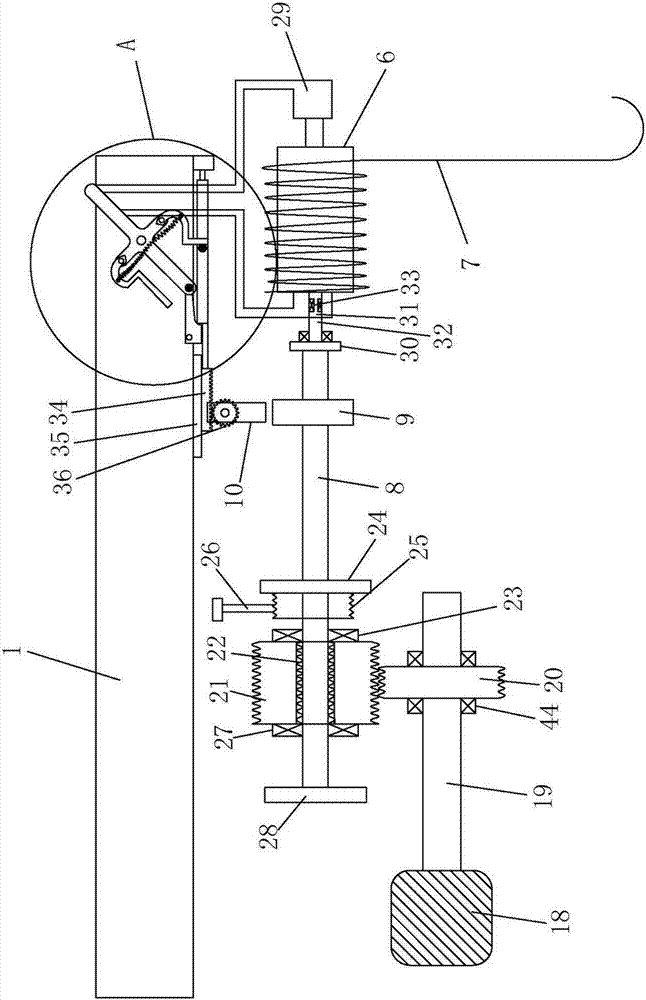

[0025] Embodiment 1. The present invention mainly consists of three parts: lifting device, braking device, and driving device. The lifting device mainly drives the lifting of the product, and the braking device is mainly used to control the braking of the driving of the drum 6. , the driving device is mainly used to drive the start and stop of the drum 6, and all embodiments will be described in detail below.

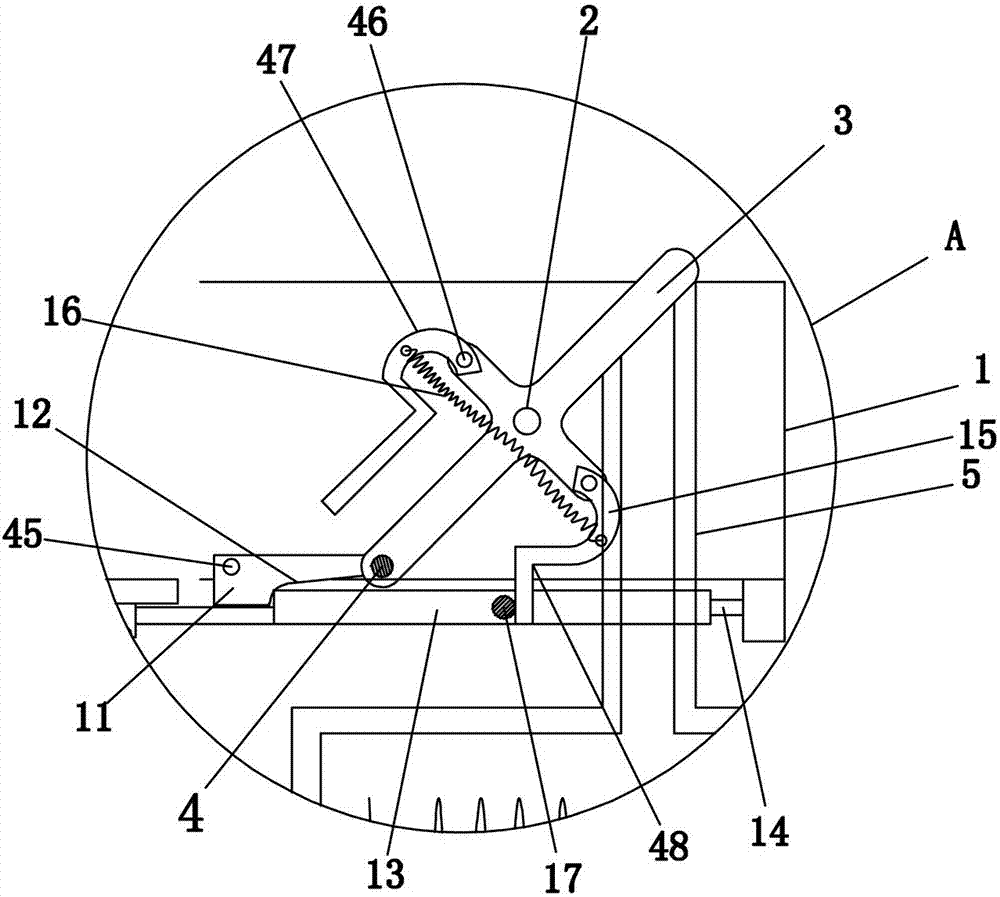

[0026] The lifting device includes a long fixed plate 1, on which a first rotating shaft 2 is arranged, and a cross rotating plate 3 is installed on the first rotating shaft 2, and the cross rotating plate 3 can rotate around the first rotating shaft 2, and the cross rotating plate 3 The oblique placement is to make one end of the cross rotating plate 3 oblique and forceful, such as figure 1 As shown, the cross rotating plate 3 is placed obliquely, and the lower end of the cross rotating plate 3 is provided with a first protrusion 4, and the upper end of the cross rotat...

Embodiment 2

[0031] Embodiment 2. On the basis of Embodiment 1, the boom 5 is rollingly connected with the drum 6. The boom 5 can not only bear the gravity of the drum 6, but also make the drum 6 rotate in the boom 5. The present invention adopts the The two ends of 5 are connected with L-shaped clamping tube 29 respectively, and clamping tube 29 can block cylinder 6, and cylinder 6 is stuck in the middle of clamping tube 29, and then realizes the rotation of cylinder 6.

Embodiment 3

[0032] Embodiment 3, on the basis of Embodiment 1, the first driving shaft 8 is connected with the first bearing seat 30 , and further connected with the drum 6 , when the first driving shaft 8 rotates, it can drive the drum 6 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com