Packaging mesh bag capable of automatic unhooking and removing, and operation method thereof

An automatic decoupling and automatic unloading technology, applied in the field of logistics, can solve the problems of wasting loading and unloading fees, high return shipping costs, inconvenient storage and recycling, etc., to improve the mechanization of logistics, save loading, unloading and return shipping costs, and shorten Effect of Intermittent Waiting Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The automatic decoupling and automatic unloading container net bag and its operation method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

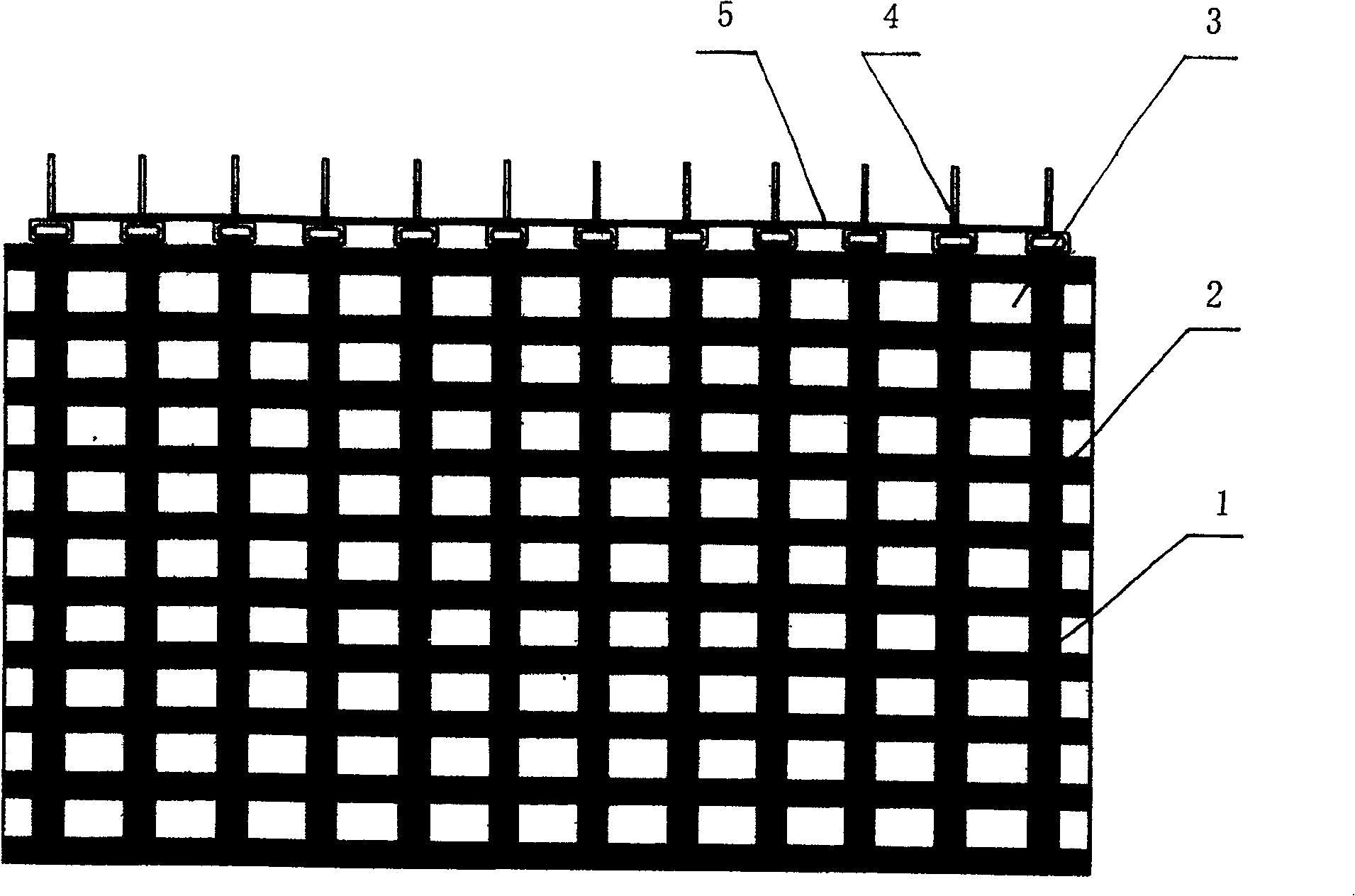

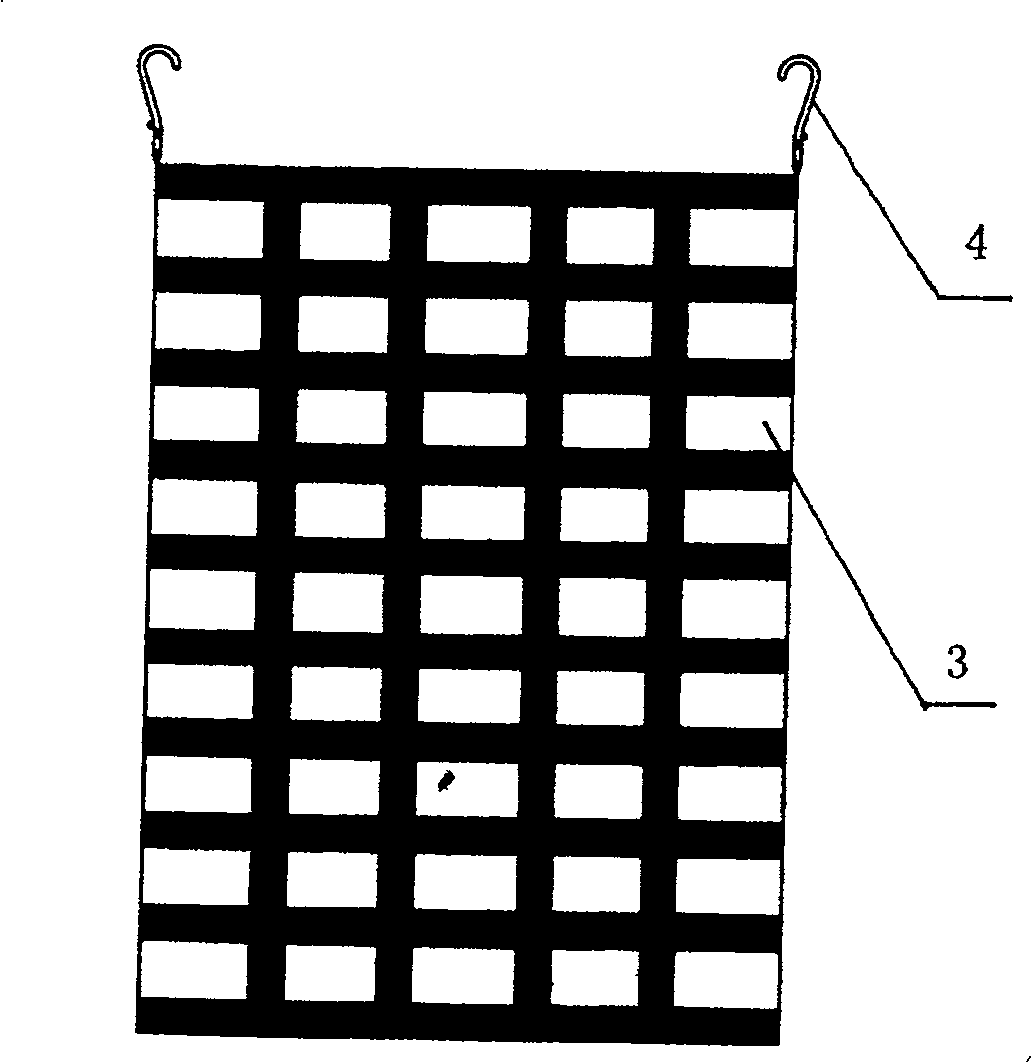

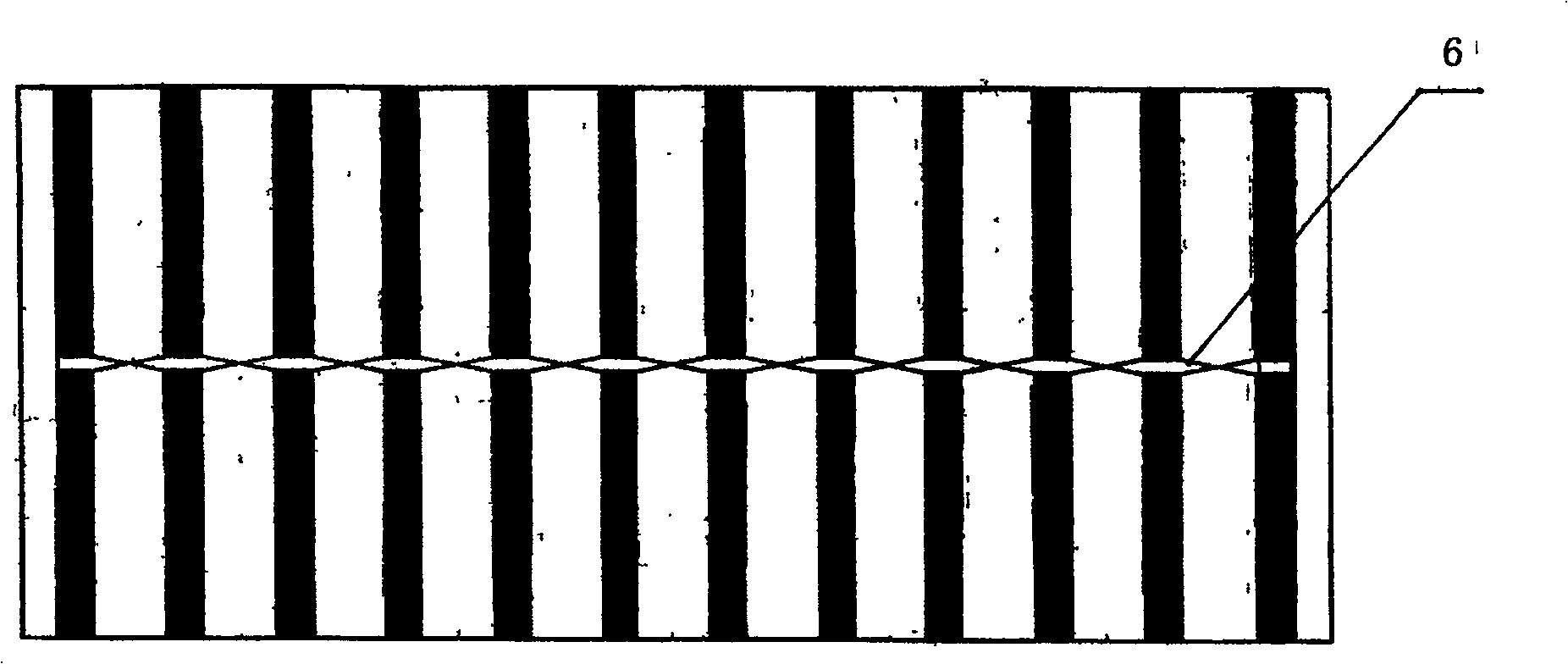

[0034] Depend on figure 1 , figure 2 It can be seen that the automatic decoupling and automatic unloading container mesh bag of the present invention comprises a rectangular mesh bag 3 made of braided straps, and the mesh bag 3 is composed of weft-arranged braided straps 1 and warp-aligned braided straps 2 separated by a certain distance. Back, left and right four sides, the intersection of described weft-arranged braided belt 1 and warp-arranged braided belt 2 is fixed with sewing method, and the edge of the front and rear two sides of described mesh bag 3 upper mouth is provided with and every A hook 4 that is flexibly connected to the end of the weft-arranged braided belt 1, the hooks 4 on the front and rear sides are respectively welded to a steel bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com