A wheel detection device

A detection device and wheel technology, applied in wheel testing and other directions, can solve the problems of wheel smashing and injury to workers, heavy wheel weight, time-consuming and labor-intensive, etc., and achieve the effect of protecting wheels, reducing energy consumption, and ensuring detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

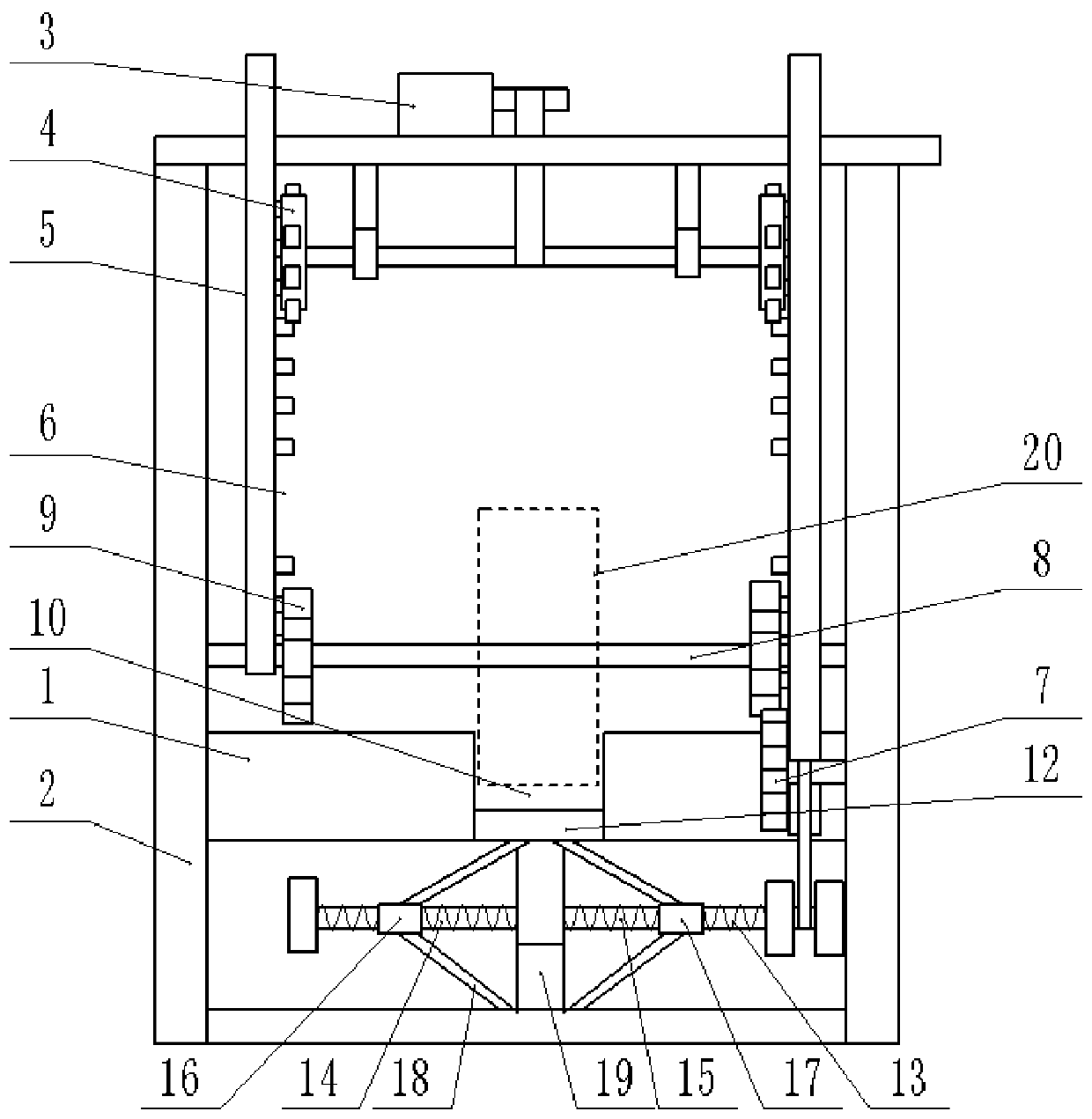

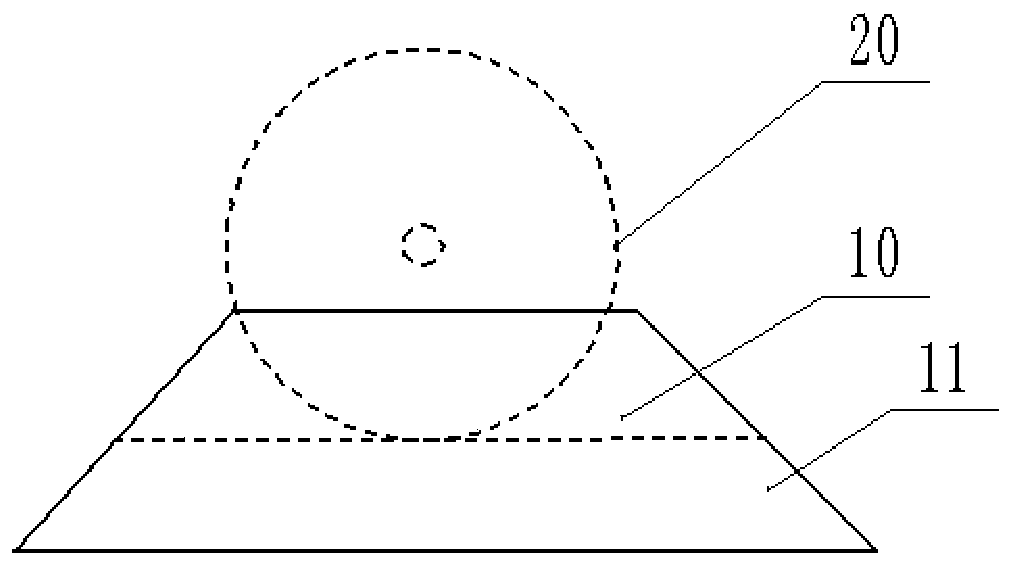

[0016] The reference signs in the drawings of the description include: machine 1, frame 2, motor 3, lifting gear 4, rack 5, notch 6, transmission gear 7, horizontal shaft 8, turning gear 9, positioning groove 10, inclined rail 11. Bottom plate 12, threaded rod 13, first threaded part 14, second threaded part 15, first sliding sleeve 16, second sliding sleeve 17, first inclined arm 18, support column 19, wheel 20.

[0017] The embodiment is basically as figure 1 Shown: a wheel detection device, including a machine 1, a frame 2 is provided on the machine 1, a motor 3 and two sets of first lifting mechanisms are arranged on the frame 2, and the two sets of first lifting mechanisms are respectively located on the frame 2 left and right. The first lifting mechanism includes a meshing lifting gear 4 and a rack 5. A gear shaft is welded and fixed between the two lifting gears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com