Time sequence inner extending type collecting mechanism

A rack and motor technology, applied in the field of time-sequential internal expansion picking mechanism, can solve the problems of waste of physical and mental resources of workers, non-continuity of production process, enhanced machine wear, etc., so as to improve the level of production automation, realize periodicity and Continuity, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

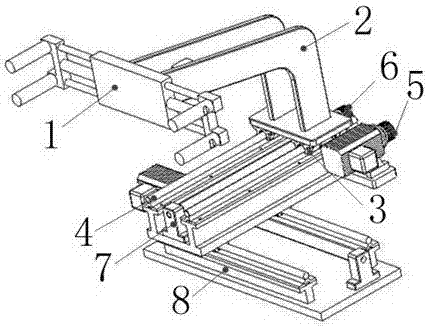

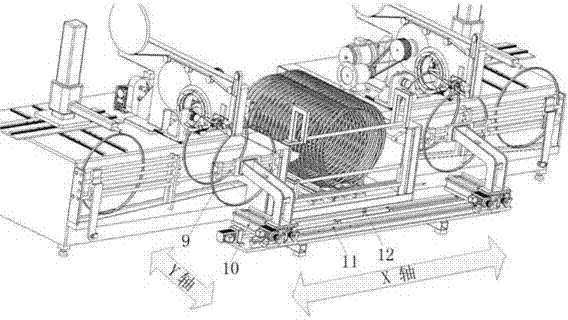

[0014] The structural composition of the present invention is as figure 1 with figure 2 shown. The time sequence internal expansion picking mechanism is supported by a two-way expansion cylinder (1), an L-shaped frame (2), a chute (3), a linear guide rail (4), an electric motor (5), a nut screw (6), and a nut screw Seat (7), support base plate (8), winding steel ring (9), short guide rail (10), long guide rail (11), shift fork (12) is formed. The two-way expansion cylinder (1) is connected with the L-shaped frame (2), and the two-way expansion cylinder (1) can perform appropriate retraction and abduction, and can complete the internal expansion clamping of the winding steel ring (9). The chute (3) is connected to the linear guide rail (4), and under the driving action of the motor (5) and the nut screw (6), through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com