Semi-active heave compensation device control system

A technology of active compensation and heave compensation, applied in drill pipe, casing, drill pipe, etc., which can solve the problems that do not involve the control of heave compensation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

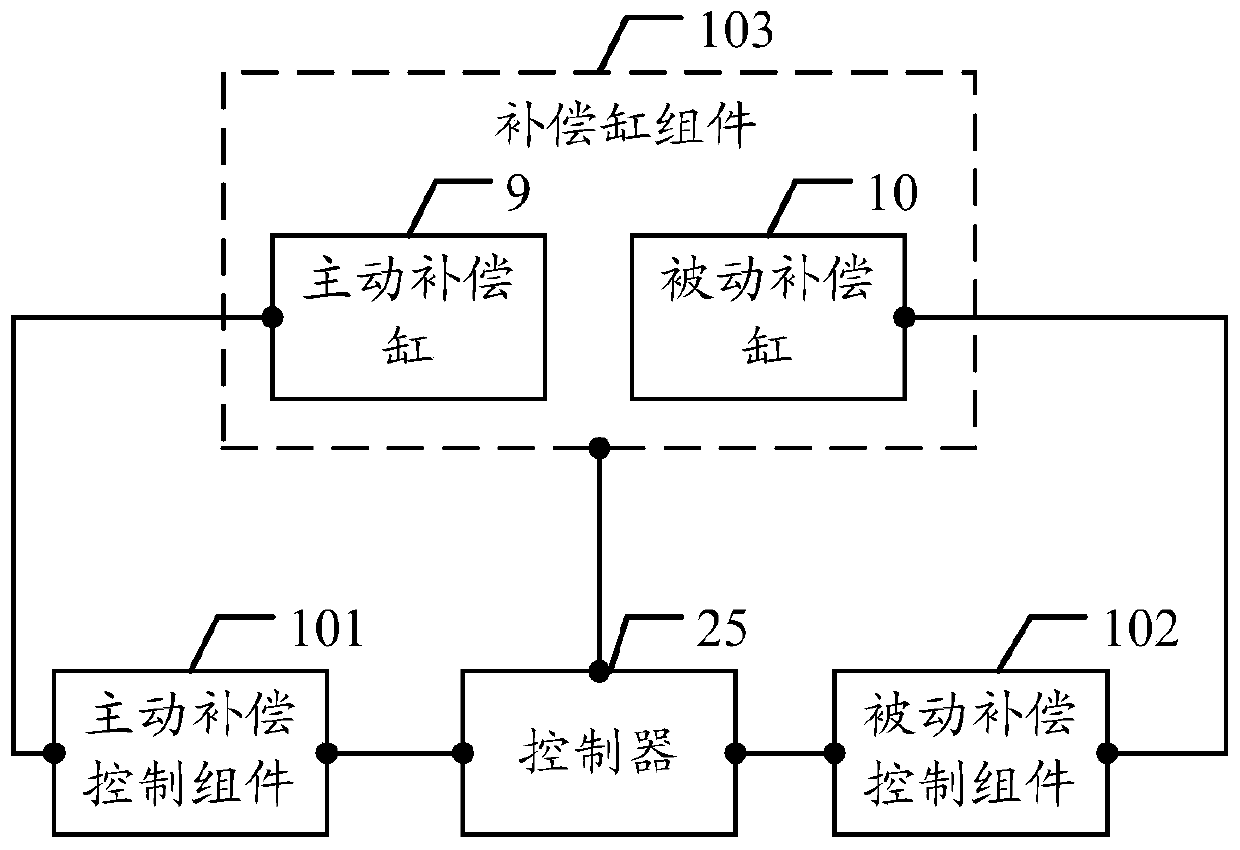

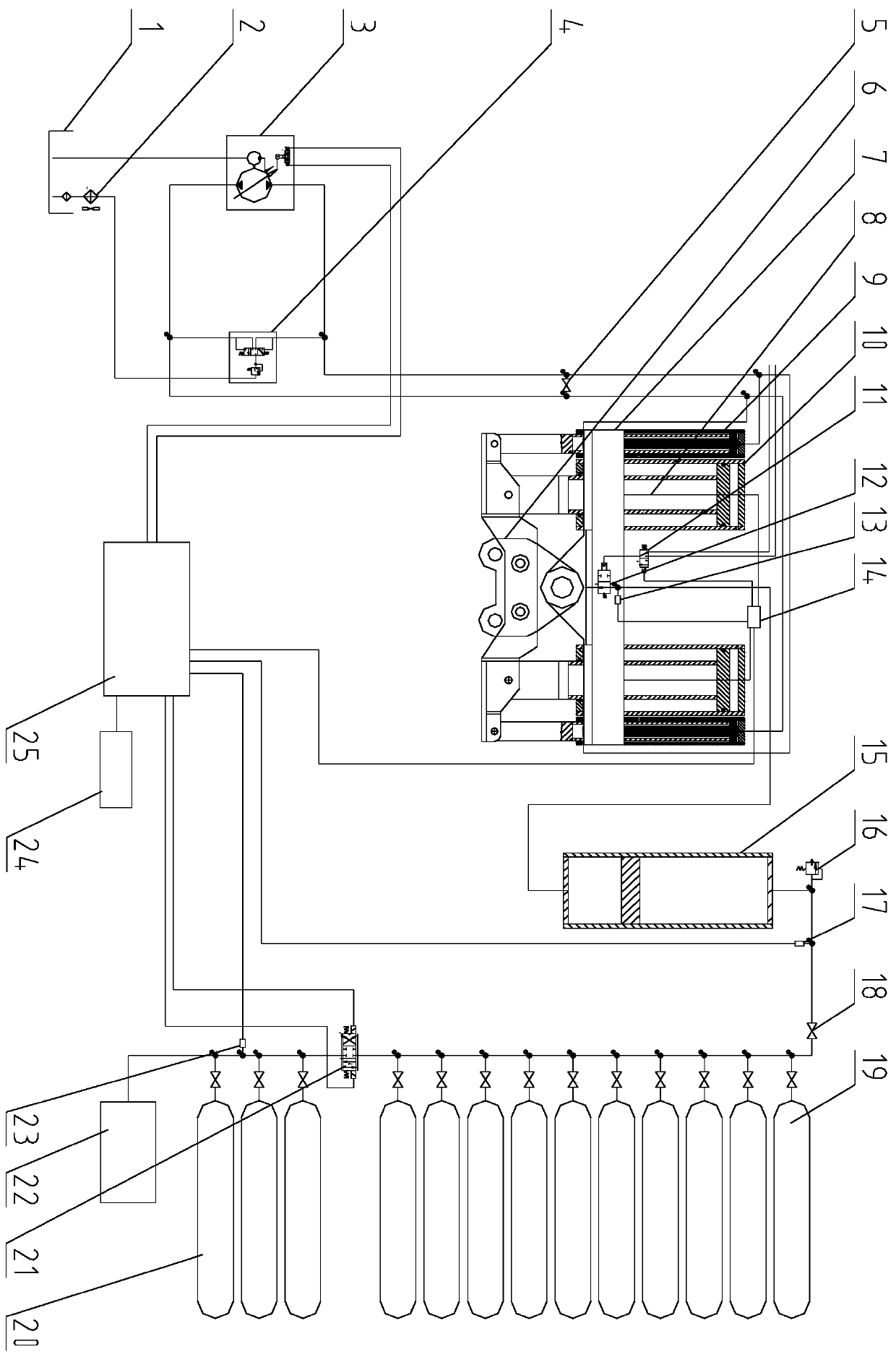

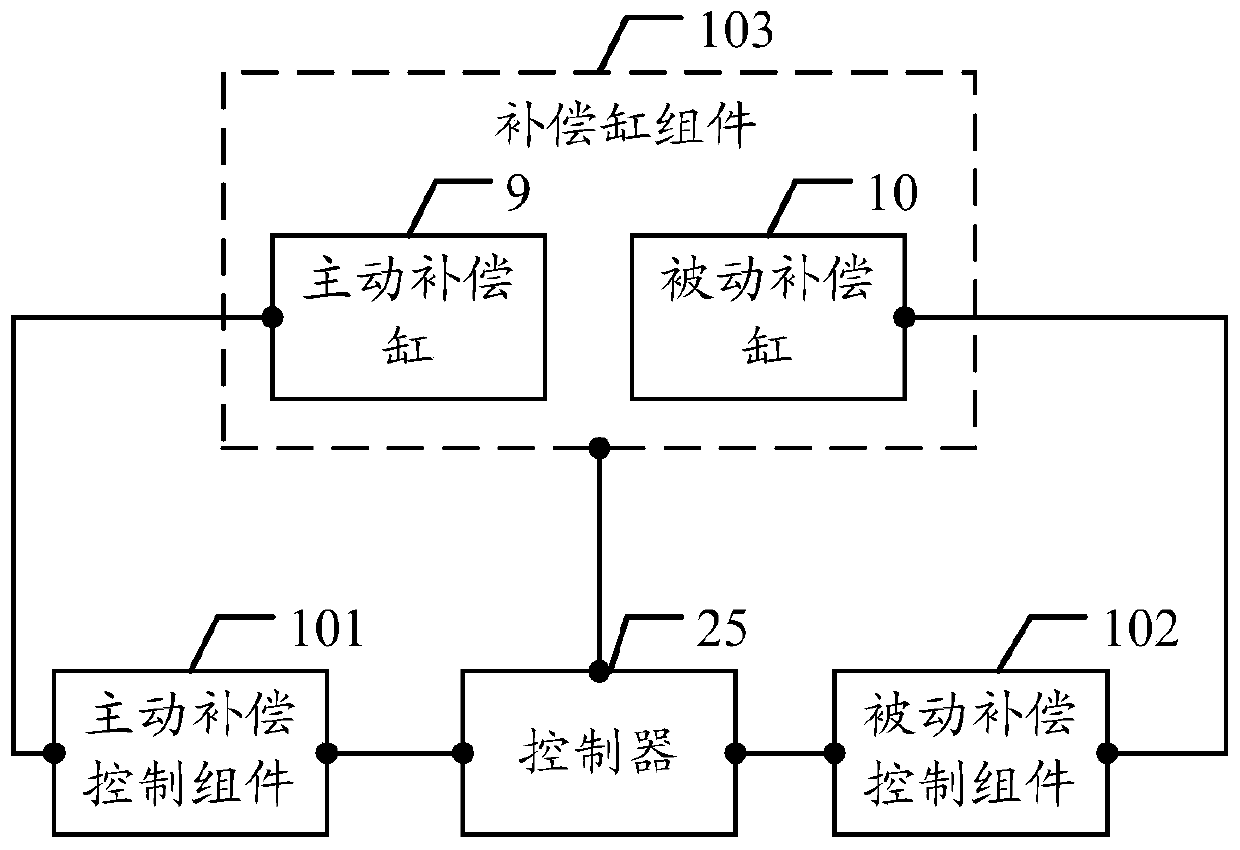

[0045] Based on the first example, see figure 2 , is a structural schematic diagram of the control system of the semi-active heave compensation device in the second embodiment of the present invention, the control system includes the controller 25 in the first embodiment, the active compensation control component 101, the passive compensation control component 102 and the compensation cylinder component 103, and the content is the same as that described in the first embodiment, and will not be repeated here.

[0046] In the embodiment of the present invention, the active compensation control assembly 101 includes: a hydraulic oil tank 1, a variable displacement pump 3;

[0047] The hydraulic oil tank 1 is connected to the variable pump 3, and the variable pump 3 is connected to the active compensation cylinder 9 and connected to the controller 25;

[0048] The variable pump 3 is used to transmit the hydraulic oil in the hydraulic oil tank 1 to the active compensation cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com