Roller type jacking excavator

A kind of excavator and drum-type technology, which is applied in the field of drum-type jacking excavators. It can solve the problems of poor soil-breaking ability of pipe jacking machines, manual transportation of earthwork, and slow excavation speed, so as to achieve high jacking operation efficiency and excavation. The effect of fast soil speed and enhanced soil breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

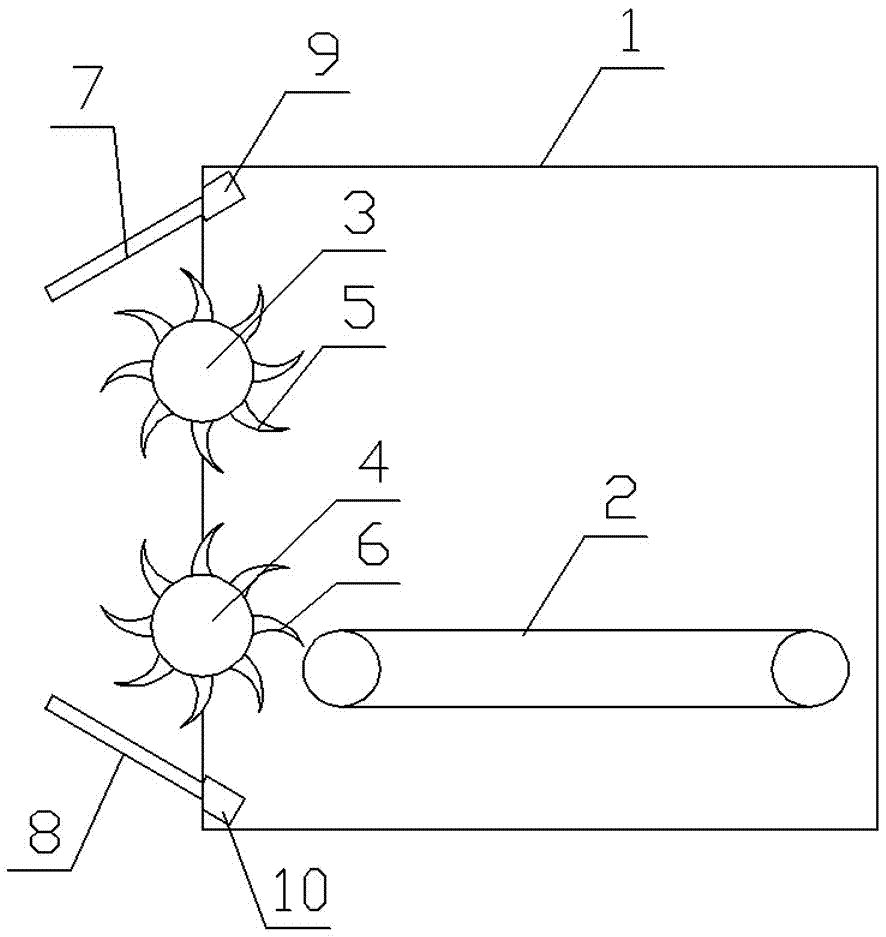

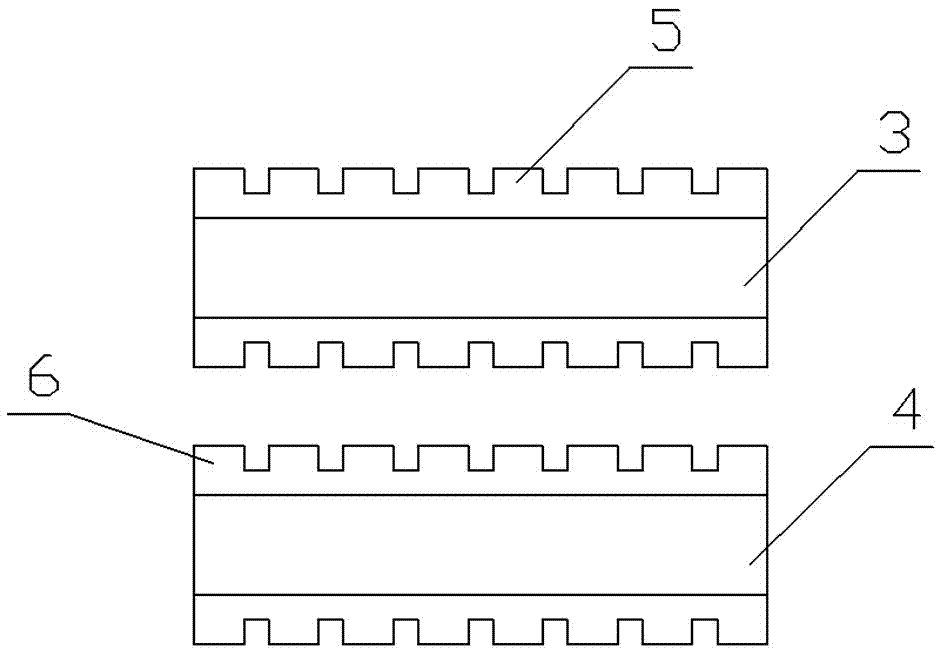

[0023] Such as figure 1 and figure 2 As shown, it includes a cylinder body 1, a roller group arranged on the front panel of the cylinder body 1, and a soil conveyor belt 2 fixed in the cylinder body 1; the roller group includes an upper roller 3 and a lower roller arranged up and down in the vertical direction 4. The two ends of the rotating shafts of the upper drum 3 and the lower drum 4 are respectively connected to the left and right side walls of the cylinder 1 in rotation; the upper drum 3 is provided with evenly distributed upper scrapers 5, and the lower drum 4 is provided with evenly distributed lower scrapers 6 , There is a gap between the upper scraper 5 and the lower scraper 6;

[0024] The rotation direction of the upper drum 3 is opposite to that of the lower drum 4; outside the cylinder body 1, the upper drum 3 rotates from top to bottom, and the lower drum 4 rotates from bottom to top.

[0025] The edge of the upper scraper 5 is bent in the direction of rotat...

Embodiment 2

[0030] Such as figure 1 and figure 2 As shown, it includes a cylinder body 1, a roller group arranged on the front panel of the cylinder body 1, and a soil conveyor belt 2 fixed in the cylinder body 1; the roller group includes an upper roller 3 and a lower roller arranged up and down in the vertical direction 4. The two ends of the rotating shafts of the upper drum 3 and the lower drum 4 are respectively connected to the left and right side walls of the cylinder 1 in rotation; the upper drum 3 is provided with evenly distributed upper scrapers 5, and the lower drum 4 is provided with evenly distributed lower scrapers 6 , There is a gap between the upper scraper 5 and the lower scraper 6;

[0031] The rotation direction of the upper drum 3 is opposite to that of the lower drum 4; outside the cylinder body 1, the upper drum 3 rotates from top to bottom, and the lower drum 4 rotates from bottom to top.

[0032] The edge of the upper scraper 5 is bent in the direction of rotat...

Embodiment 3

[0036] Such as figure 1 and figure 2 As shown, it includes a cylinder body 1, a roller group arranged on the front panel of the cylinder body 1, and a soil conveyor belt 2 fixed in the cylinder body 1; the roller group includes an upper roller 3 and a lower roller arranged up and down in the vertical direction 4. The two ends of the rotating shafts of the upper drum 3 and the lower drum 4 are respectively connected to the left and right side walls of the cylinder 1 in rotation; the upper drum 3 is provided with evenly distributed upper scrapers 5, and the lower drum 4 is provided with evenly distributed lower scrapers 6 , There is a gap between the upper scraper 5 and the lower scraper 6;

[0037] The rotation direction of the upper drum 3 is opposite to that of the lower drum 4; outside the cylinder body 1, the upper drum 3 rotates from top to bottom, and the lower drum 4 rotates from bottom to top.

[0038] The edge of the upper scraper 5 is bent in the direction of rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com