Compound planetary friction drive

A technology of friction drive and composite planet, which is applied in the direction of friction transmission, transmission, belt/chain/gear, etc. It can solve the problems that the contact force of small friction drive cannot be guaranteed, and the compound drive is not attractive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

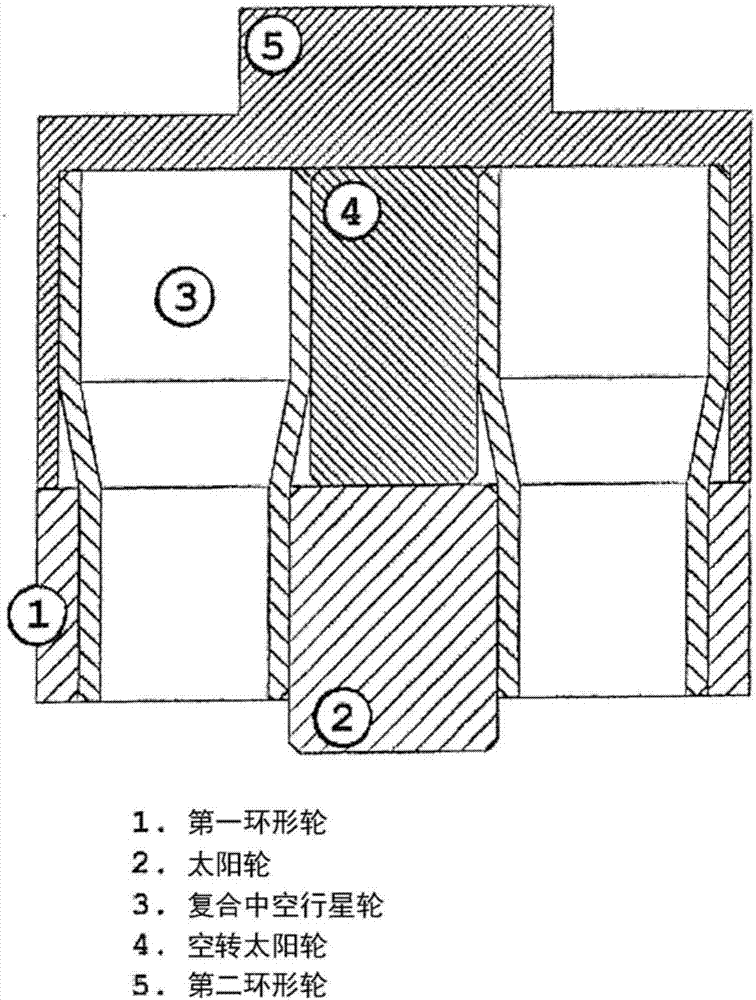

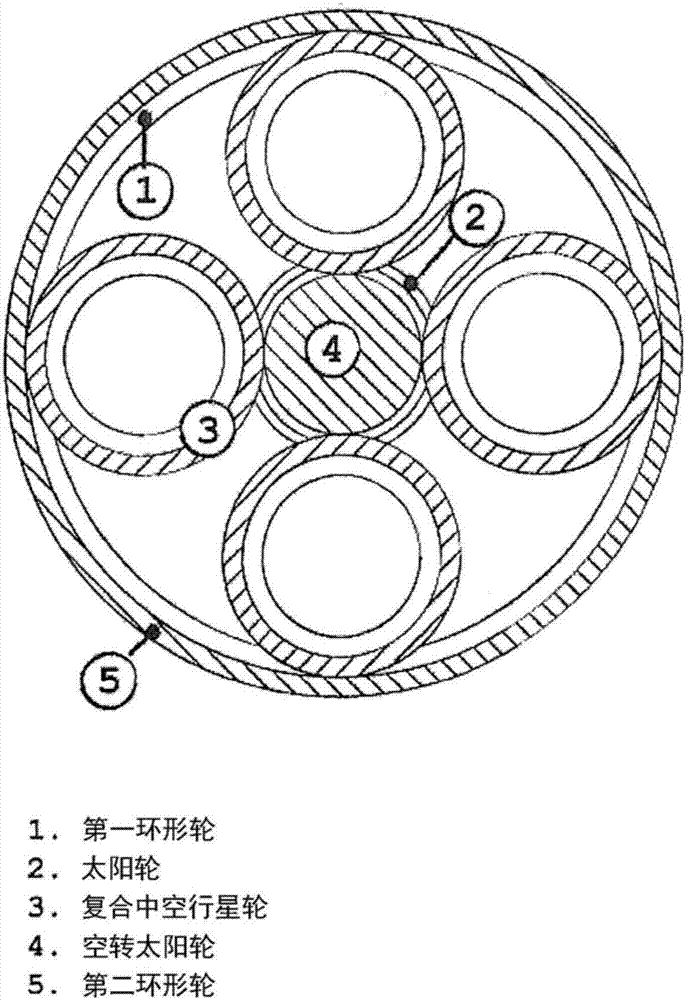

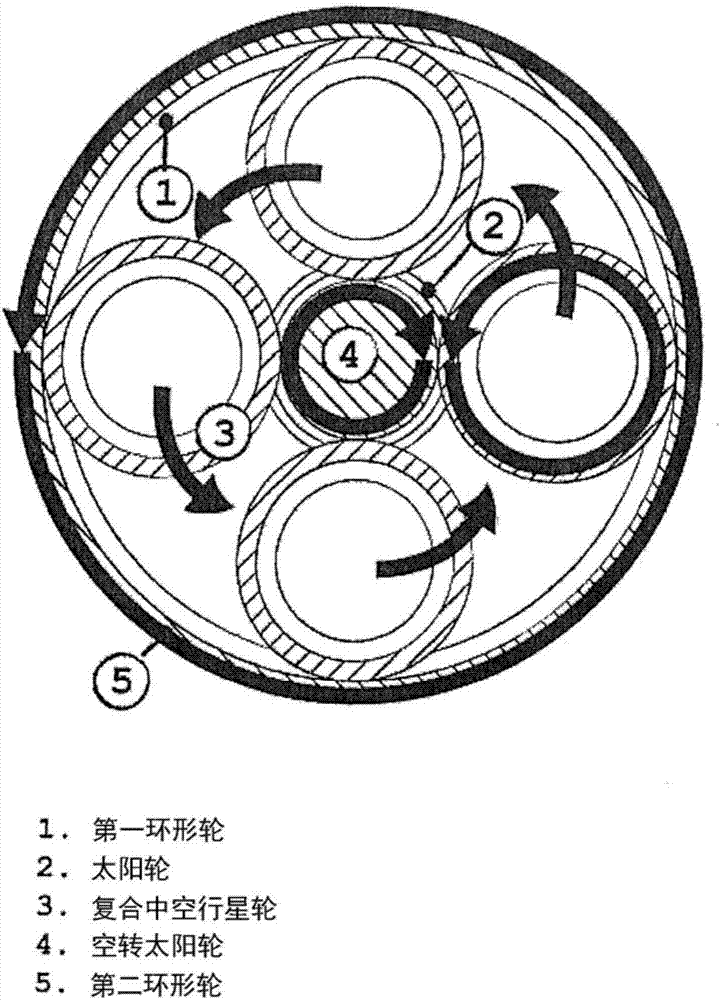

[0021] reference figure 1 with figure 2 , Shows an exemplary compound planetary friction drive device according to the first basic embodiment, which is provided with a base or input first annular wheel 1. This first ring wheel 1 may for example be the housing of the "lower" part of the drive device according to the invention. The base or first annular wheel 1 can be rigidly attached to a fixed environment, or to an engine housing or power source structure. In addition, the compound planetary friction drive device has a drive or input sun gear 2, for example from a certain type of motor. The hollow composite planetary gear of the planetary friction drive device of the present invention is denoted by reference numeral 3. Each planetary gear 3 is, for example, a hollow tube, with a slight size difference between the "lower" part and the "upper" part of the tube. There is a transition zone between the "lower" and "upper" of the tube; this will be discussed below Figure 4 In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com