Rotary Ring Soil Trough Test Bench Drive Mechanism

A technology of annular soil trough and drive mechanism, which is applied in the testing of transmission devices, mechanical equipment, and mechanical components, etc., can solve the problems of inconsistency, inaccurate rotation speed of annular soil trough, and decrease in the quality of detection and test, and achieve reliable driving engagement and transmission. The effect of high precision and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

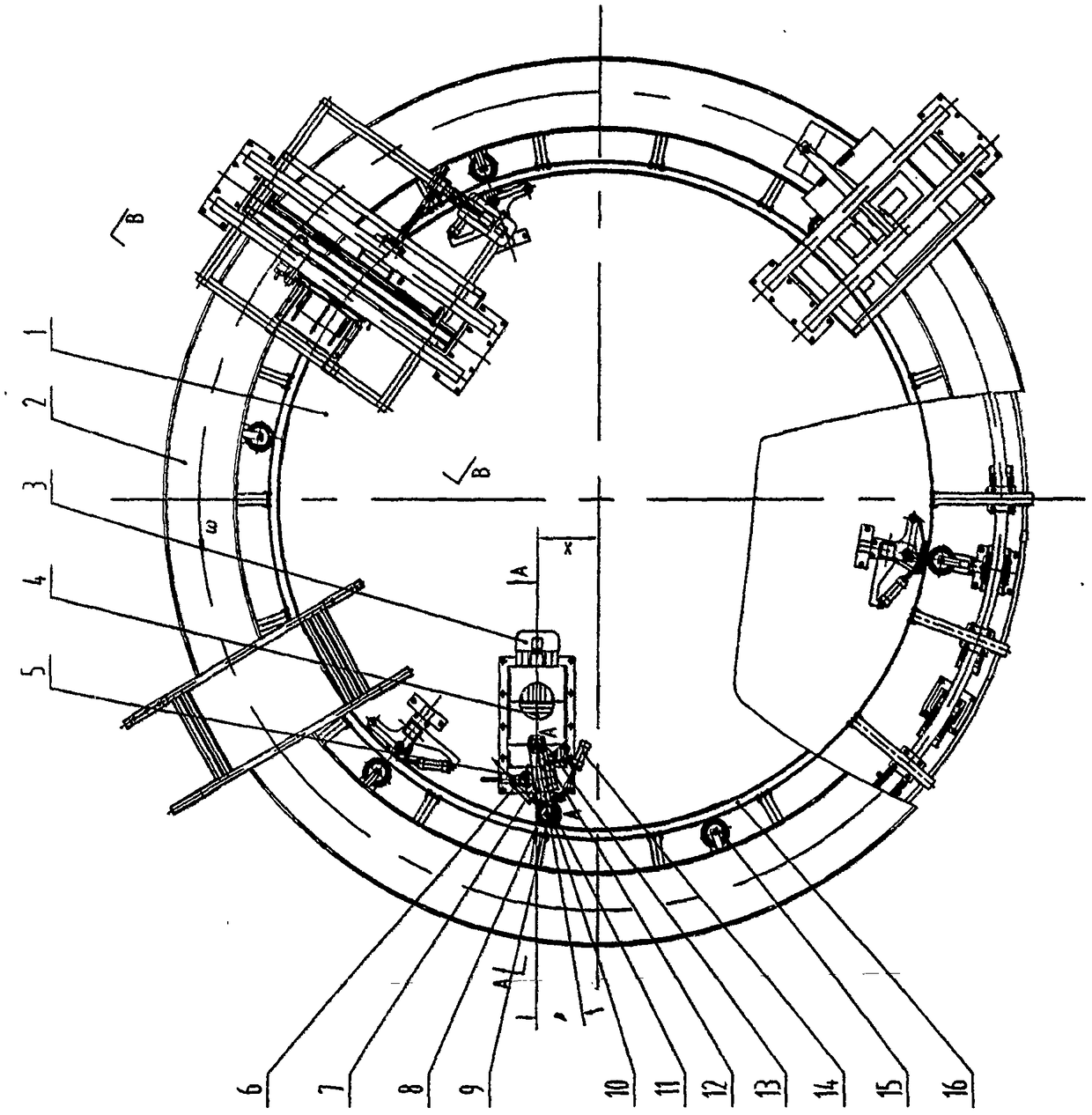

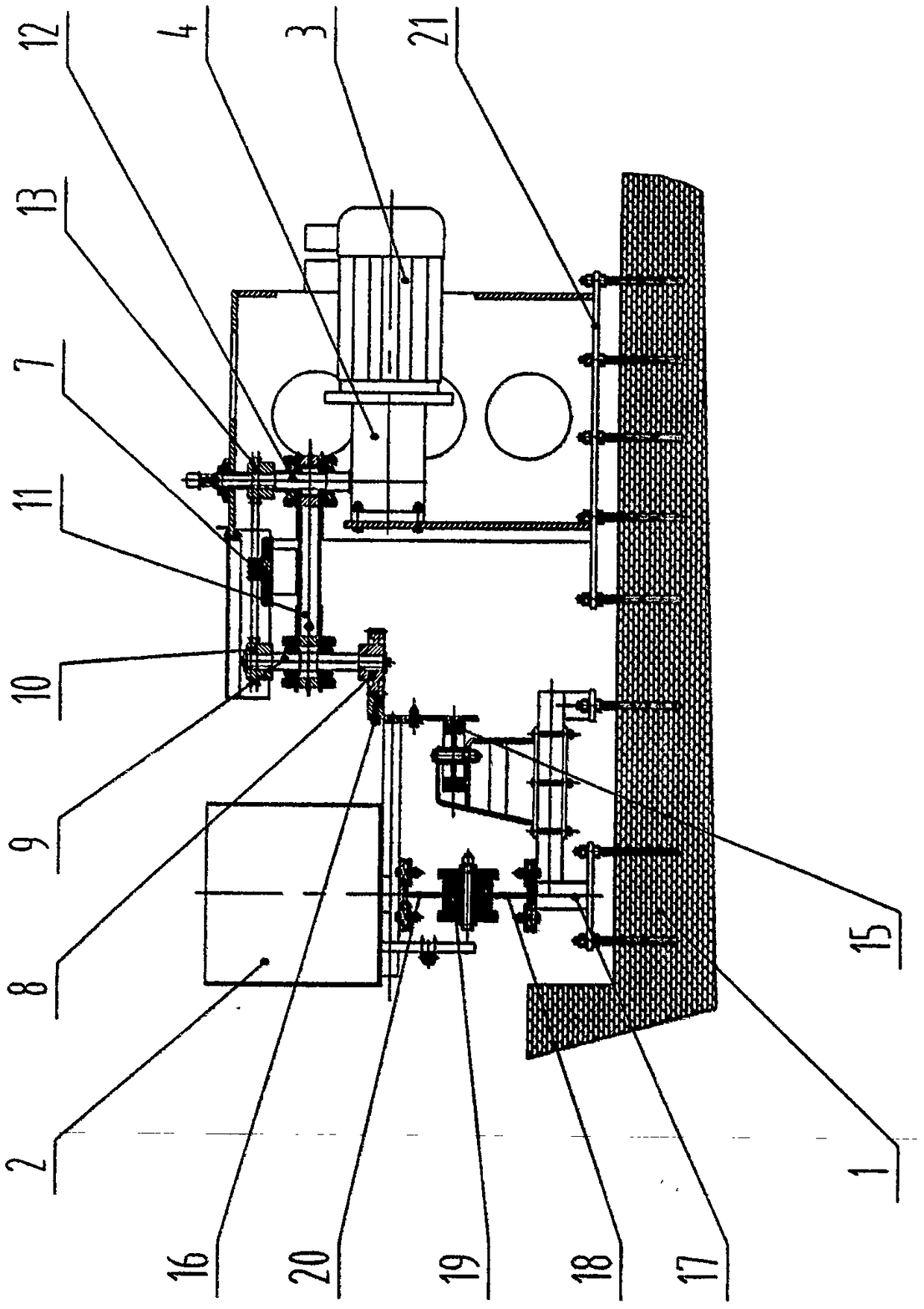

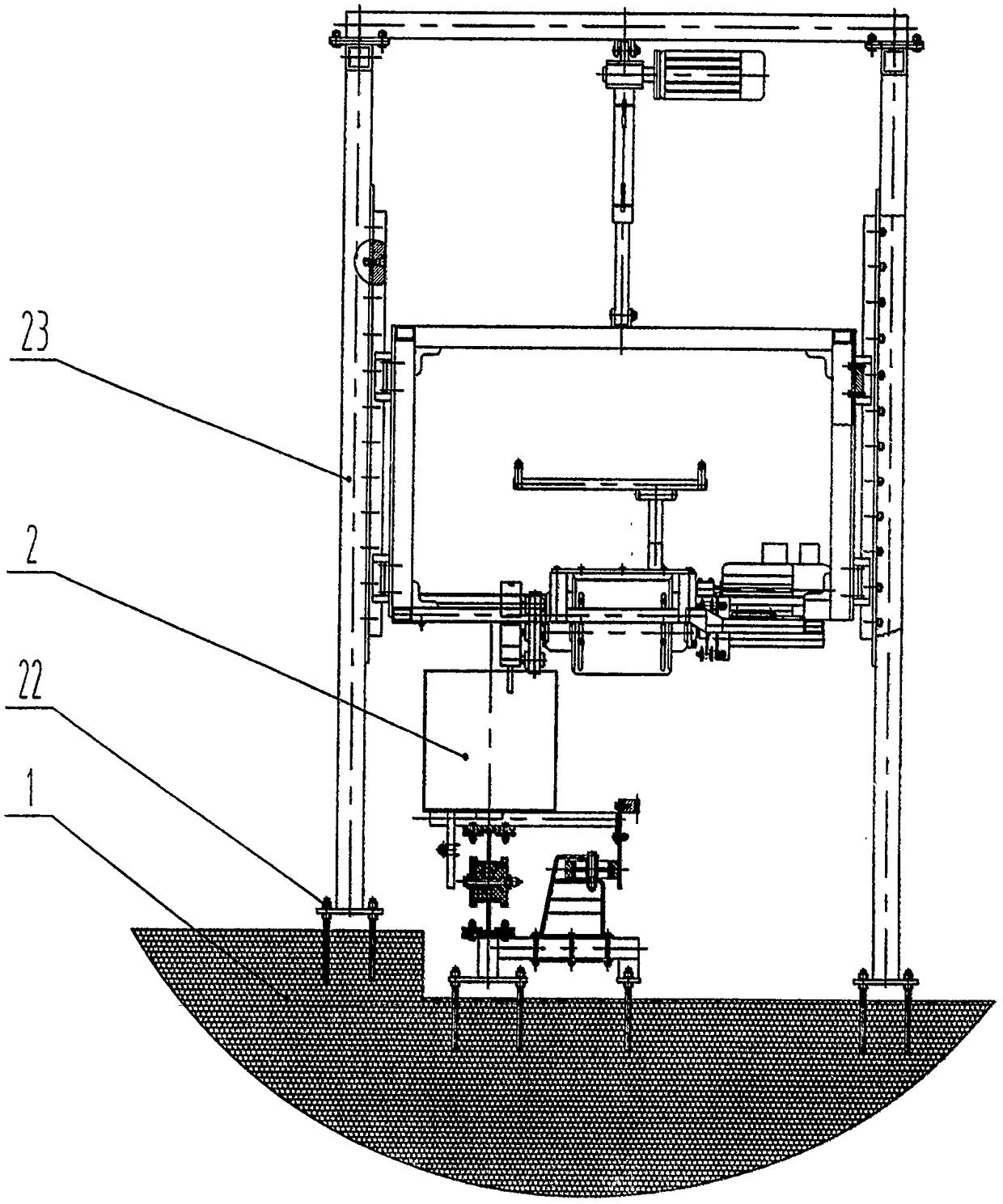

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A rotary annular soil tank test bench drive mechanism, a circular track support 17 is fixed on the outer edge of the base 1, and an annular lower track 18 with soil tank rollers 19 is fixed on the circular track support 17, The ring-shaped soil tank 2 is fixed on the ring-shaped upper track 20, the soil tank roller 19 is arranged on the position between the ring-shaped upper and lower tracks 20, 18, and the ring-shaped soil tank 2 is rotatably supported and installed on the ring-shaped lower track by the soil tank roller 19 18, the combined ring gear 16 is fixed on the annular inner part of the annular soil tank 2, and a plurality of center positioning rollers 15 are evenly distributed along the circumferential direction on the annular track support 17, and the center positioning The roller 15 is in contact with the cylindrical outer wall of the combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com