Multi-dimension optical fiber light permeation unit and manufacturing process thereof

A manufacturing process and multi-dimensional technology, applied in the field of materials, can solve problems such as low cement adhesion, difficulty in mass and rapid production, poor concrete dyeing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

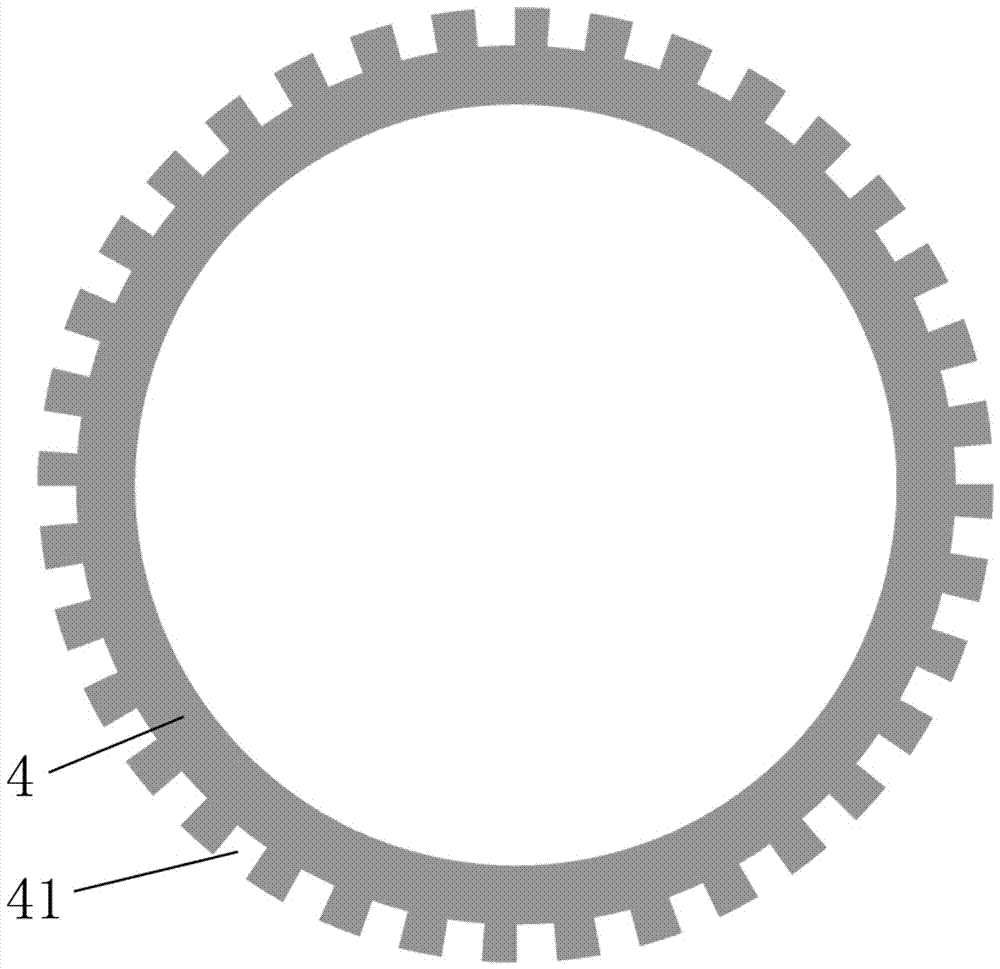

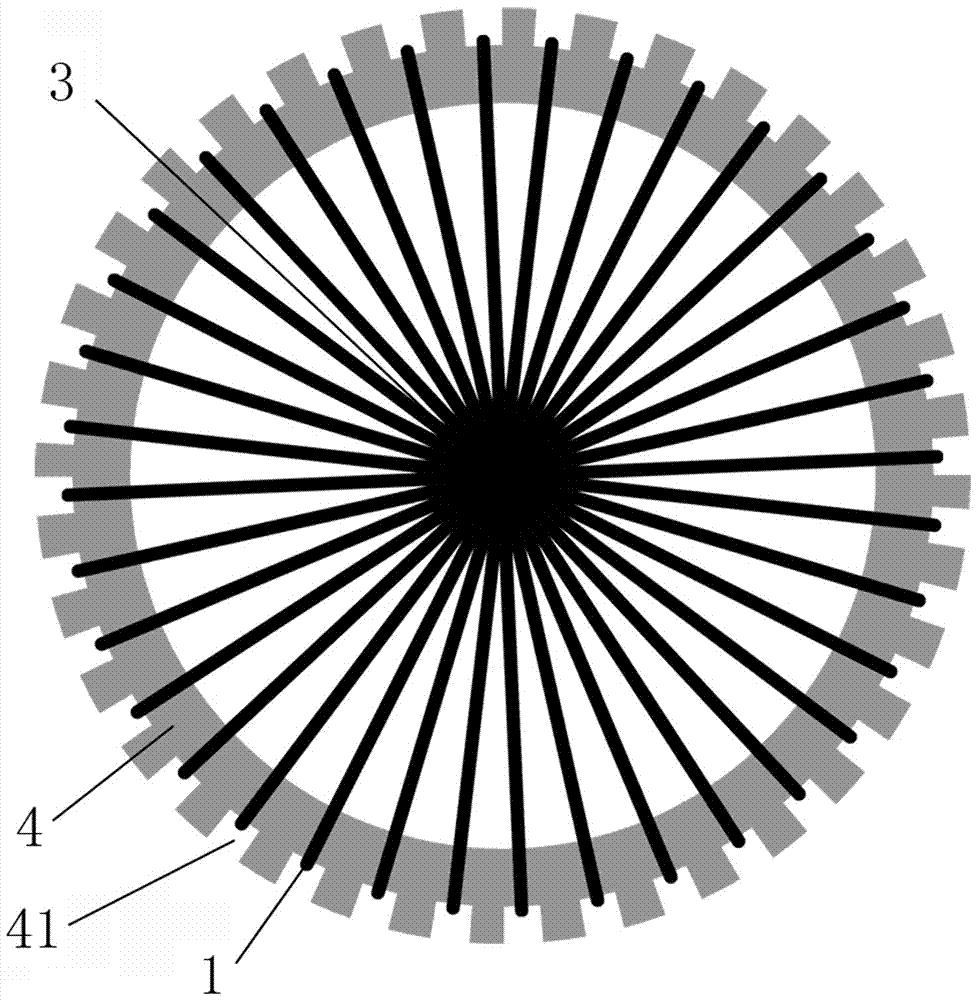

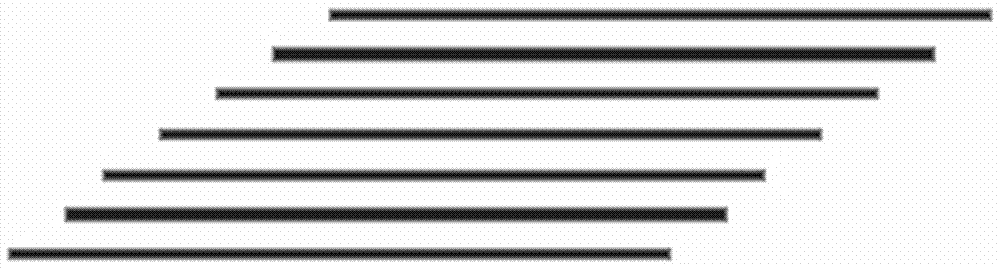

[0048] Such as Figure 1-7 As shown, the product of this embodiment is a multi-dimensional optical fiber 1 light-transmitting body, which includes a light-guiding optical fiber 1 and a light-transmitting carrier 2. Several optical fibers 1 form a sheet-shaped optical fiber fabric unit 3, and the optical fiber fabric unit 3 is layered They are arranged in the light-transmitting carrier 2 sequentially from bottom to top, and both ends of each optical fiber 1 are located at the outer edge of the light-transmitting carrier 2. The fiber fabric unit 3 layer by layer can customize the density and arrangement of each layer of optical fibers 1 to achieve multi-dimensional light transmission without dead ends.

[0049] The optical fiber fabric unit 3 of this embodiment is composed of several optical fibers 1 arranged in one direction, two directions or multiple directions, and they are woven on the same plane. Different from the traditional one-way light transmission, this product can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com