Generalized prediction control algorithm of continuous stirring tank reactor system

A generalized predictive control, reactor system technology, applied in the direction of adaptive control, general control system, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

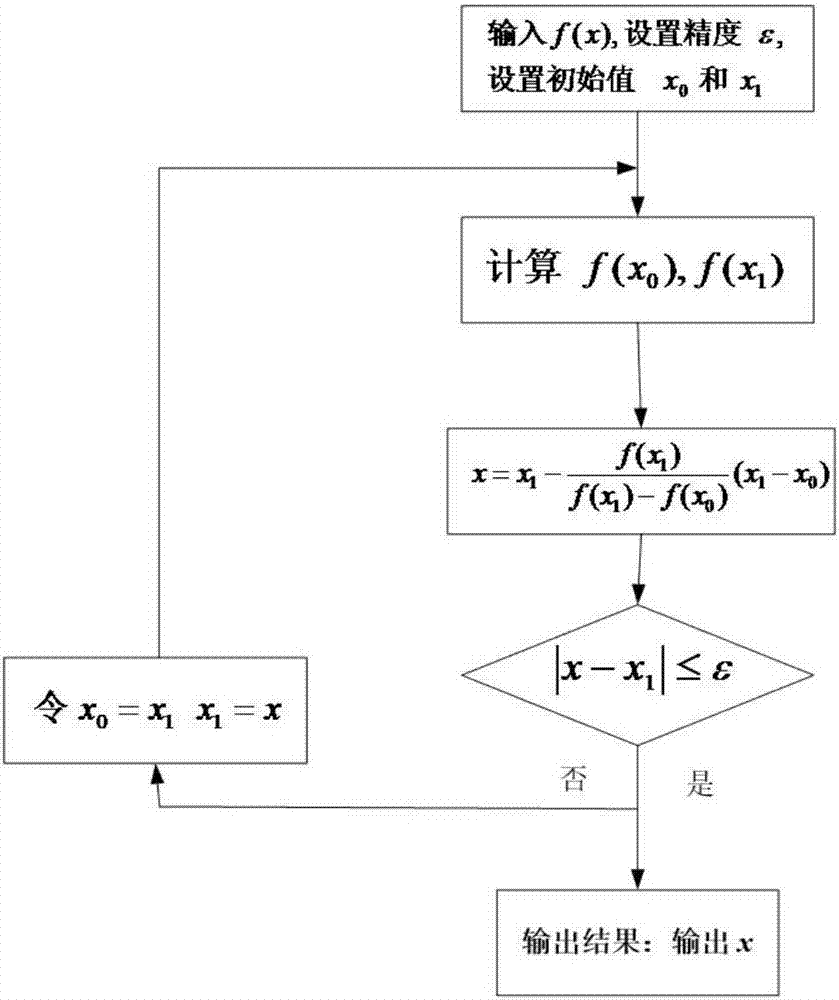

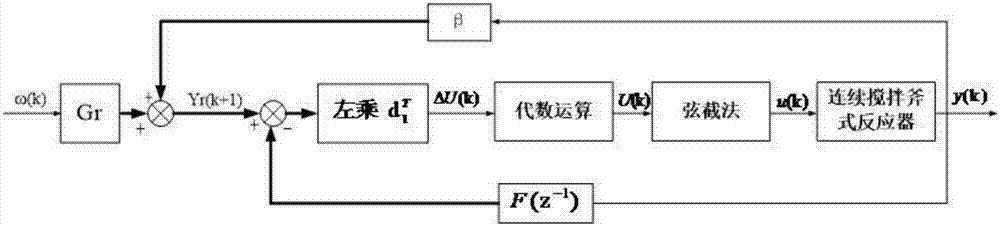

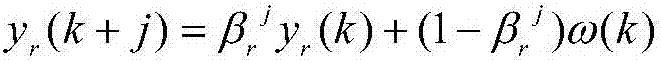

[0045] like figure 1 and figure 2 Shown, the present invention has designed a kind of generalized predictive control algorithm of continuous stirred tank reactor system (CSTR), in practical application, specifically comprises the following steps:

[0046] Step 1. Construct the nonlinear model structure corresponding to the continuous stirred tank reactor system (CSTR) as follows:

[0047]

[0048] Among them: y represents the concentration of a reactant in the continuous stirred tank reactor system (CSTR), as the output of the continuous stirred tank reactor system (CSTR); u represents the reactant entering the continuous stirred tank reactor system (CSTR ), as the input of the continuous stirred tank reactor system (CSTR), represents the controller output in the control system design.

[0049] Then, the Taylor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com