Fryer for river snail rice noodles

A frying pan and snail noodle technology, applied in the direction of oil/fat baking, etc., can solve the problems of time-consuming and labor-intensive scalding, and achieve the effects of saving oil consumption, saving costs, and avoiding food safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below with reference to the embodiments of the drawings:

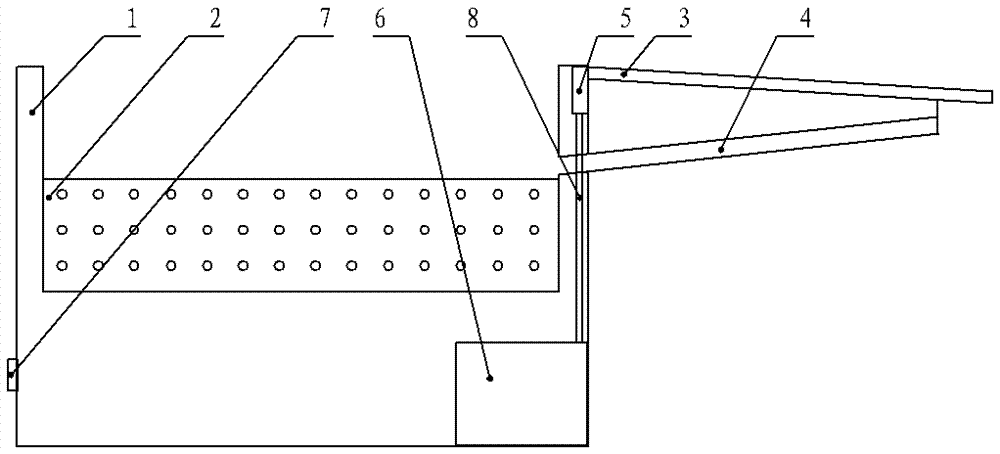

[0012] Such as figure 1 In the illustrated embodiment, the fryer for snail flour includes a casing 1, an oil-containing cavity 2, a frying basket, an oil filter rack 3 and an oil receiving groove 4 located below it, and a vibrator installed at the left end of the oil filter rack 5. Motor 6 and switch 7. The vibrator 5 is connected to the motor 6 through the shaft 8; the left end of the oil filter holder 3 is located on the upper part of the casing 1, and the right end is inclined downward so that the dishes can automatically vibrate to the right under the vibration of the vibrator; the left end of the oil tank 4 is connected to the machine Shell 1 is connected and leads to the oil containment chamber 2 at the position above the frying basket, and the right end is diagonally upward and connected to the oil filter frame 3, so that the oil dripped from the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com