Circular mould granulator with easily cleaned conditioner

A technology of conditioner and granulator, applied in the direction of die extrusion granulation, etc., can solve the problems of reducing work efficiency, increasing cleaning cost, wasting raw materials, etc., and achieving the effects of simple structure, convenient cleaning and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

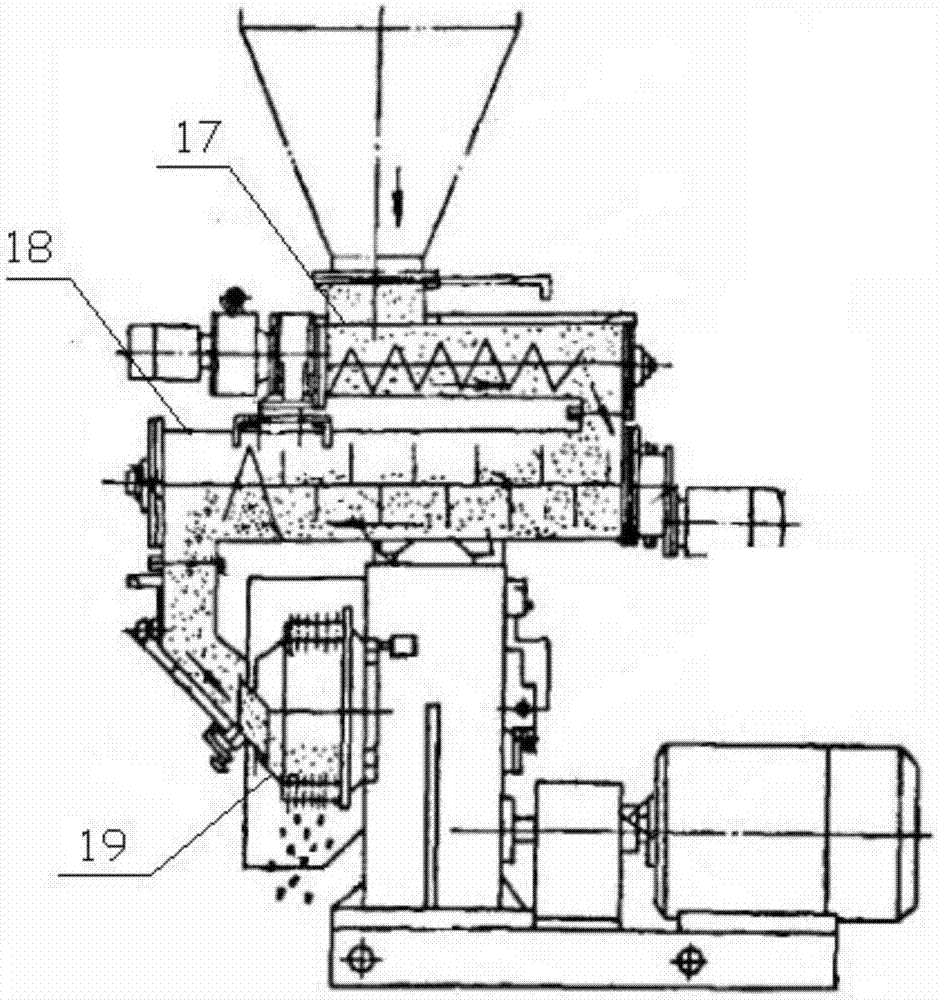

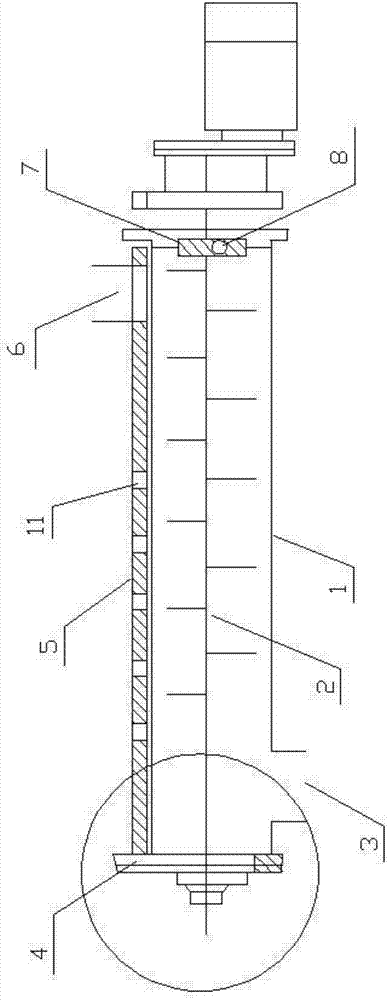

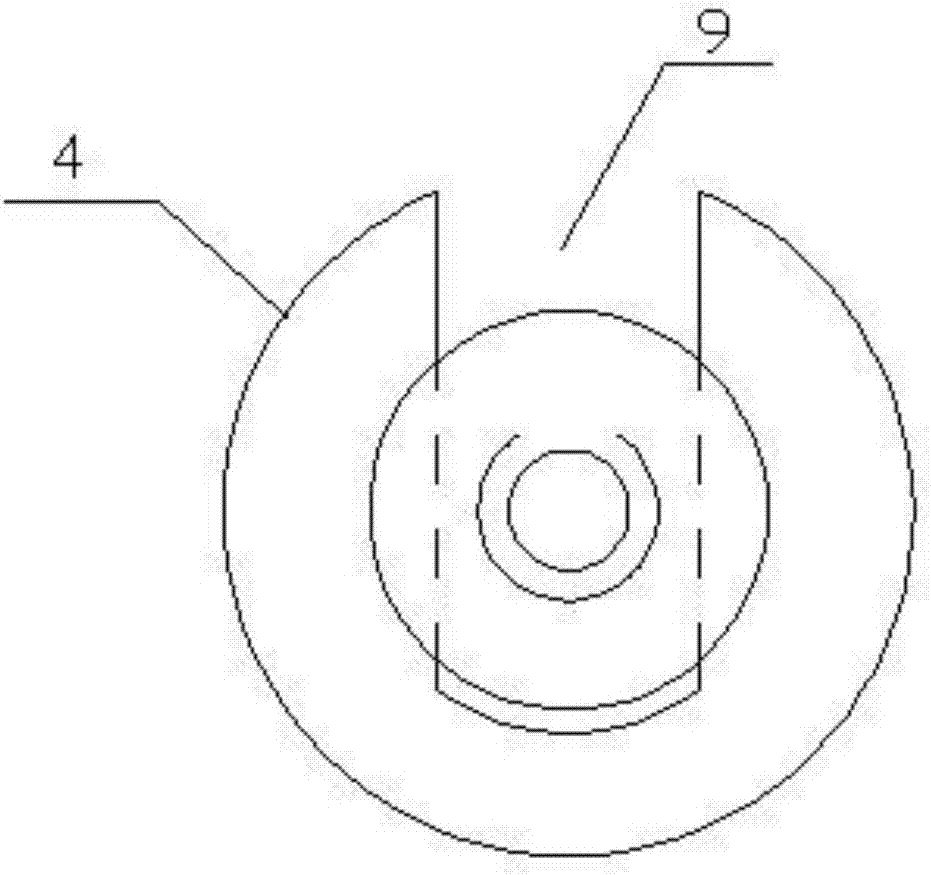

[0019] refer to Figure 1-5 , a ring die granulator with an easy-to-clean conditioner, including a feeding mechanism 17, a conditioner 18 and a granule maker 19, the conditioner includes a horizontal cylinder 1, the cylinder 1 One end is provided with a fixed end cover 4, the fixed end cover 4 is integrated with the cylinder body 1, the other end of the cylinder body 1 is provided with a movable end cover, and the top of the cylinder body 1 is provided with a strip-shaped opening 10 extending to the two ports of the cylinder body , the elongated opening 10 is provided with a top cover 5, the top cover 5 is provided with a feed port 6, the bottom of the cylinder 1 is located at the discharge port 3, the feed port 6 and the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com