Building construction hanging frame

A technology for building construction and hangers, which is applied in the direction of construction, building structure, scaffolding supported by house structures, etc., and can solve problems such as heavy installation workload, labor and material resources consumption, and delay in construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

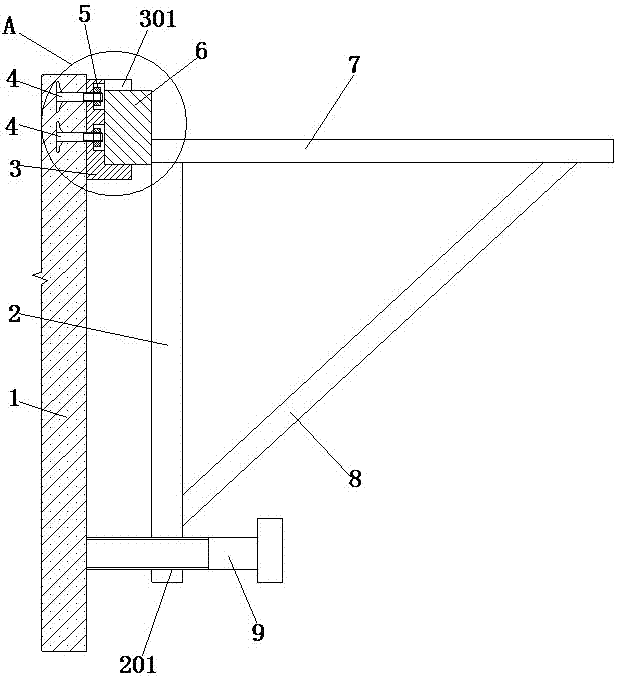

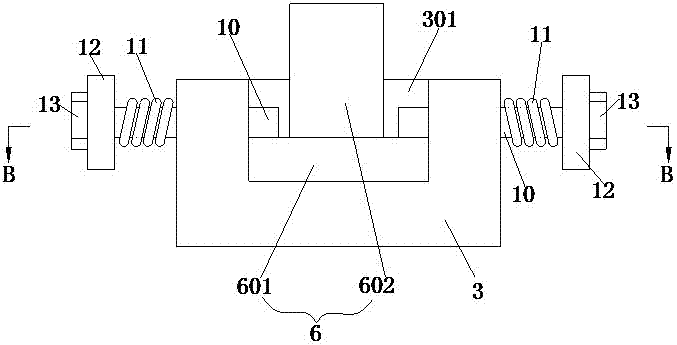

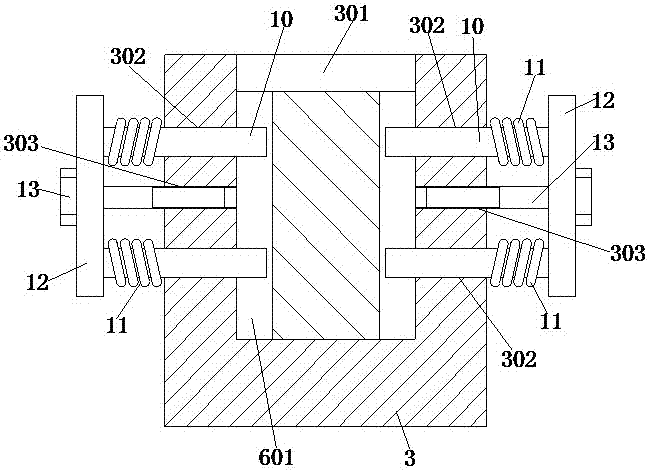

[0019] like Figures 1 to 4 As shown, a kind of building construction of the present invention is used hanger, and it comprises vertical beam 2, fixed block 3, embedded bolt 4, nut 5, connecting block 6, crossbeam 7 and oblique beam 8; One end of the beam 2 is fixedly connected to the bottom of one end of the crossbeam 7; one end of the inclined beam 8 is fixedly connected to the bottom of the other end of the crossbeam 7; the other end of the inclined beam 8 is fixedly connected to the side of the other end of the vertical beam 2; A triangular structure is formed between the vertical beam 2, the cross beam 7 and the inclined beam 8; the front end of the fixed block 3 is provided with an open slot 301; the bottom of the inner cavity of the open slot 301 is provided with several counterbores 301a; The rear end surface of the fixed block 3 is provided with a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com