Shield-tunnel lining segment T-shaped seam two-sealing-pad waterproof test device and method

A technology for gasket waterproofing and lining segments, which is applied in fluid tightness testing, measuring devices, and testing of machine/structural components, etc. It can solve problems such as the inability to scientifically simulate the waterproof effect of waterproof gaskets, and achieve high model accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

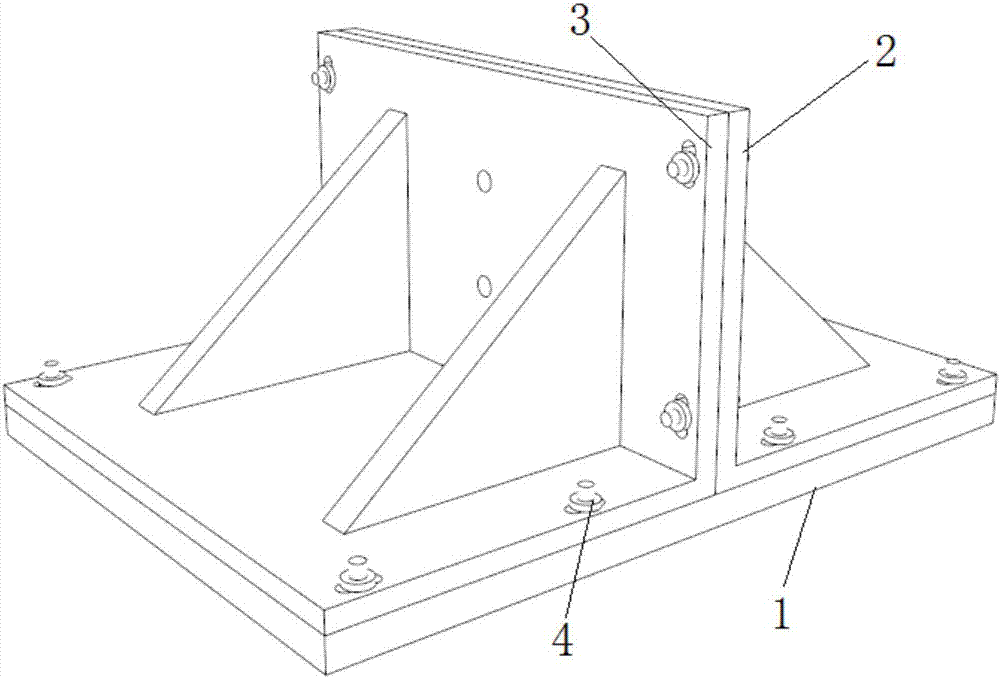

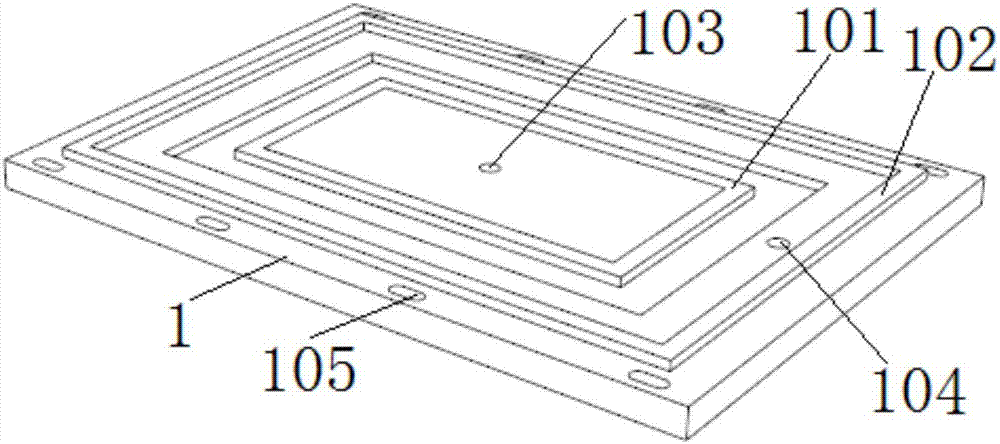

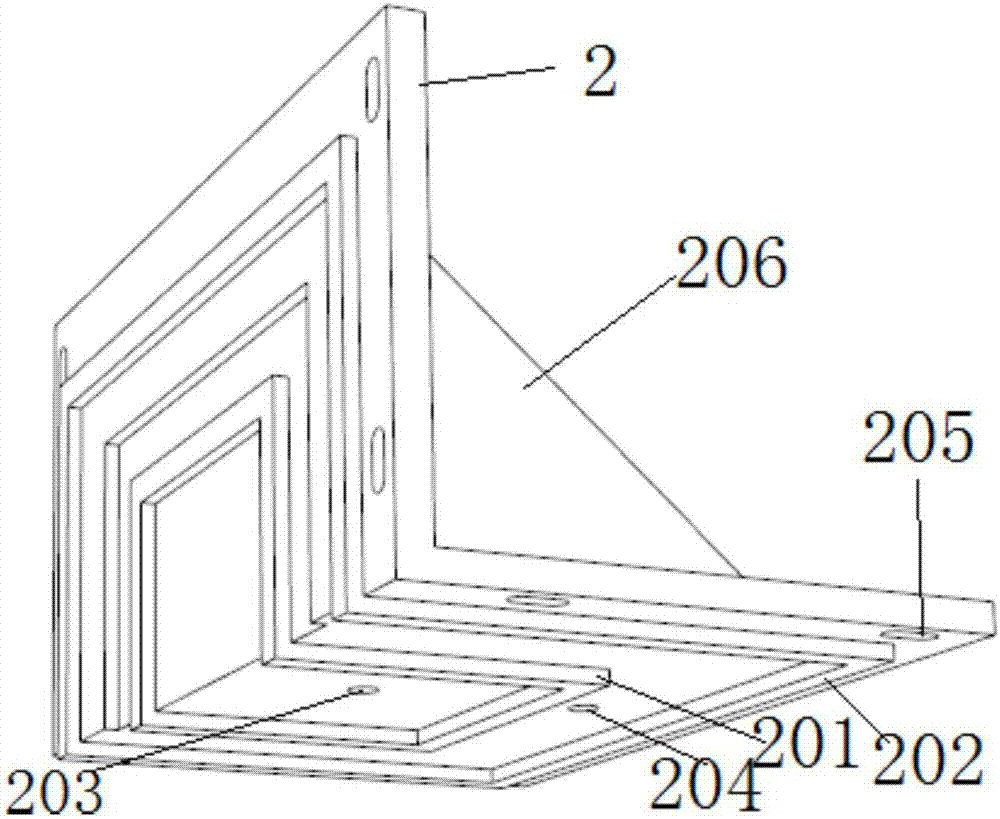

[0054] In this embodiment, a shield tunnel lining segment T-shaped seam waterproof test device with two gaskets, such as figure 1 As shown, by setting the inner and outer grooves of the lower trial mold and the upper right trial mold to different height differences, after installing two elastic gaskets, pressing the three trial molds tightly, the lower part of the T-shaped seam can be created The two waterproof sealing strips of the "一" seam and the upper "∣" seam respectively have a working condition where one opening is 0 and the other side has a certain opening, and then the water is injected and drained through two sets of water injection and drainage channels. 1. The air in the second sealing chamber is discharged, and finally passes through the water injection channel of the first sealing chamber, injecting water from the center, simulating the situation where high-pressure water breaks through two T-shaped elastic gaskets in turn, so as to achieve accurate measurement of...

Embodiment 2

[0073] In the shield tunnel lining segment T-joint waterproof test device for two seals in this embodiment, the inner ring of the upper left outer groove and the inner ring of the upper right outer groove on the T-shaped horizontal side are provided with rectangular grooves. , the inner ring of the lower outer groove is a plane; the inner ring of the upper left outer groove located on the vertical side of the T shape is provided with a rectangular groove, and the inner ring of the upper right outer groove located on the vertical side of the T shape is a plane. Other parts of the device are the same as in Example 1.

[0074]Using the test method of the shield tunnel lining segment T-shaped seam waterproof test device with two sealing pads in this embodiment, the method step 1) is:

[0075] Firstly, determine the opening value of the tension side of the two sealing pads in the lower "one" seam and the upper "∣" seam that need to be measured in the test, preferably, the lower "on...

Embodiment 3

[0078] In the shield tunnel lining segment T-joint waterproof test device for two seals in this embodiment, the inner ring of the upper left outer groove and the inner ring of the upper right outer groove on the T-shaped horizontal side are provided with rectangular grooves. , the inner ring of the lower outer groove is provided with a groove; the inner ring of the upper left outer groove located on the T-shaped vertical side is provided with a rectangular groove, and the inner ring of the upper right outer groove located on the T-shaped vertical side is provided with a groove. Has a rectangular groove. Other parts of the device are the same as in Example 1.

[0079] Using the test method of the shield tunnel lining segment T-shaped seam waterproof test device for two seals in this embodiment, the method step 1) is

[0080] Firstly, determine the opening value of the tension side of the two sealing pads in the lower "one" seam and the upper "∣" seam that need to be measured i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com