Prediction Method of Grinding Temperature in Ultrasonic Vibration Assisted Grinding of Brittle Materials

A grinding temperature and ultrasonic vibration technology, applied in computer-aided design, geometric CAD, design optimization/simulation, etc., can solve the problems of not considering ultrasonic vibration parameters and unable to reflect processing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

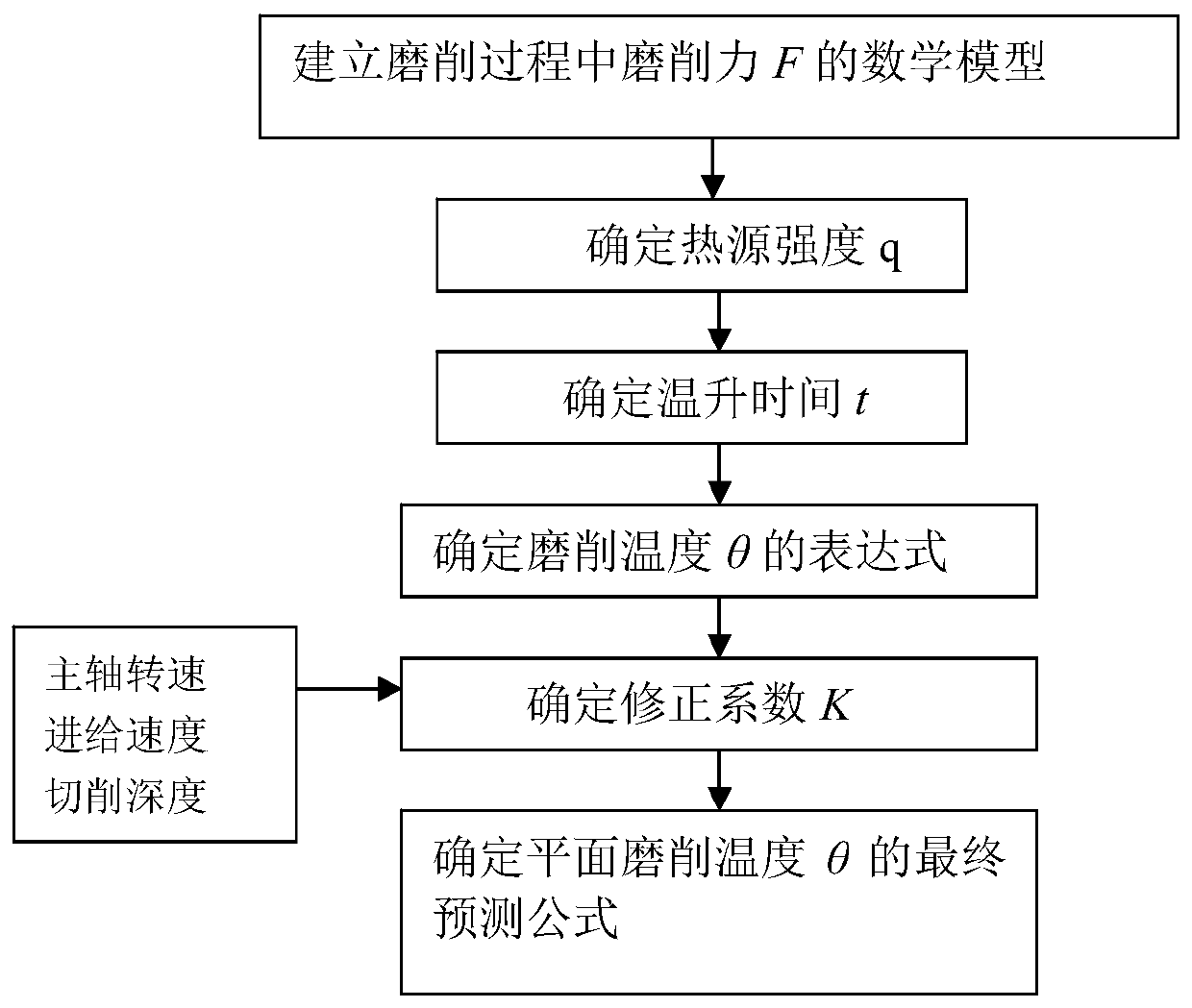

[0024] combine figure 1 , a method for predicting the grinding temperature of ultrasonic vibration-assisted grinding of brittle materials of the present invention, the specific steps are as follows:

[0025] Step 1, establish the mathematical model of the grinding force F in the grinding process; according to the relationship between the theoretical removal volume and the actual removal volume of the material, the mathematical model of the grinding force for ultrasonic vibration-assisted grinding of brittle materials is calculated as:

[0026]

[0027] In the formula, K is the correction coefficient; K 0 is a dimensionless constant; H V is the Vickers hardness of the workpiece; K IC Fracture toughness of workpiece; C 0 is a dimensionless constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com