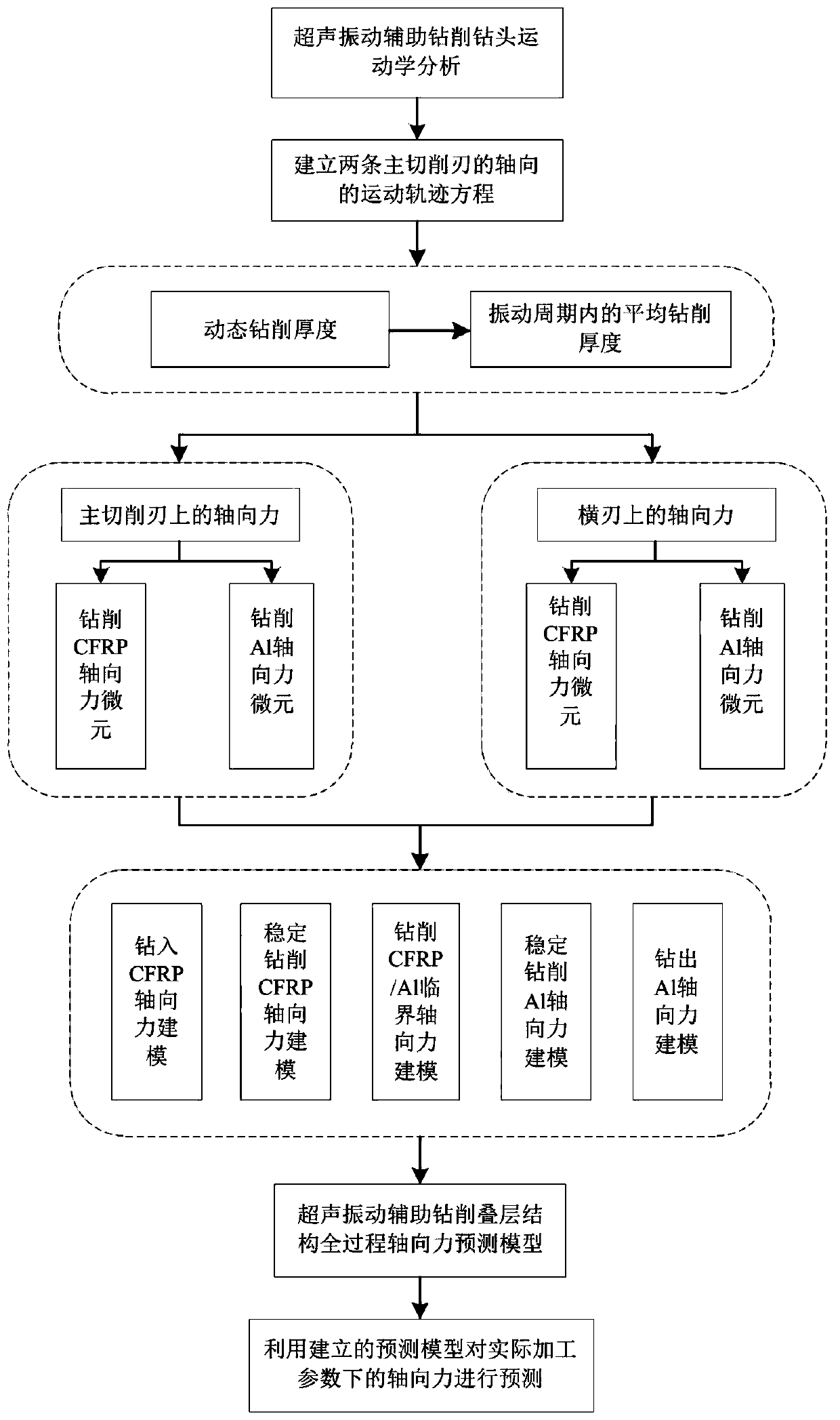

Whole-process axial force prediction method for rotary ultrasonic drilling of CFRP/Al

A technology of rotating ultrasound and axial force, which is applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate prediction accuracy and failure to take modeling into account, and achieve the goal of improving prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

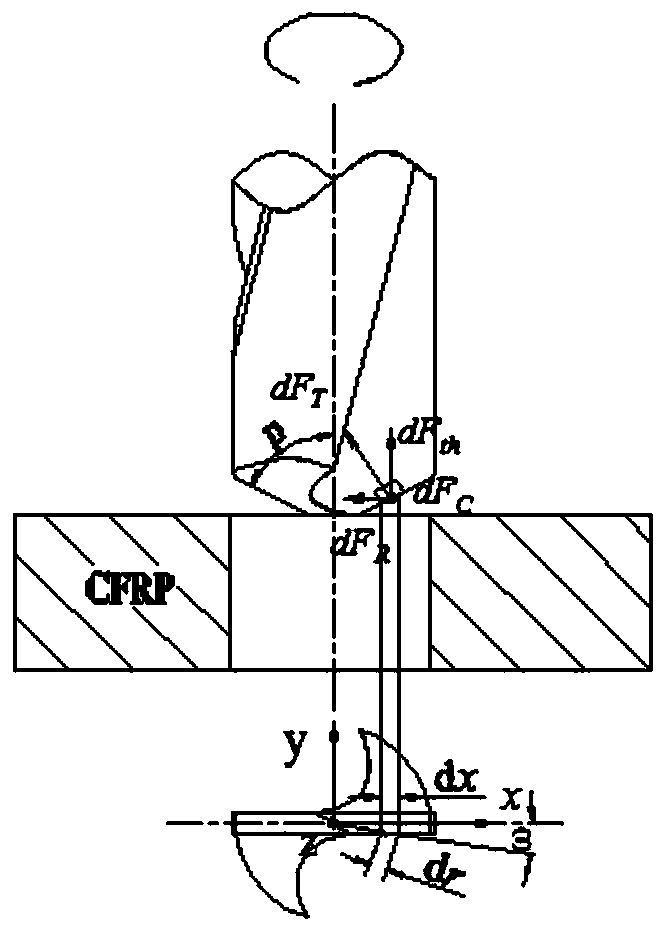

Method used

Image

Examples

Embodiment 1

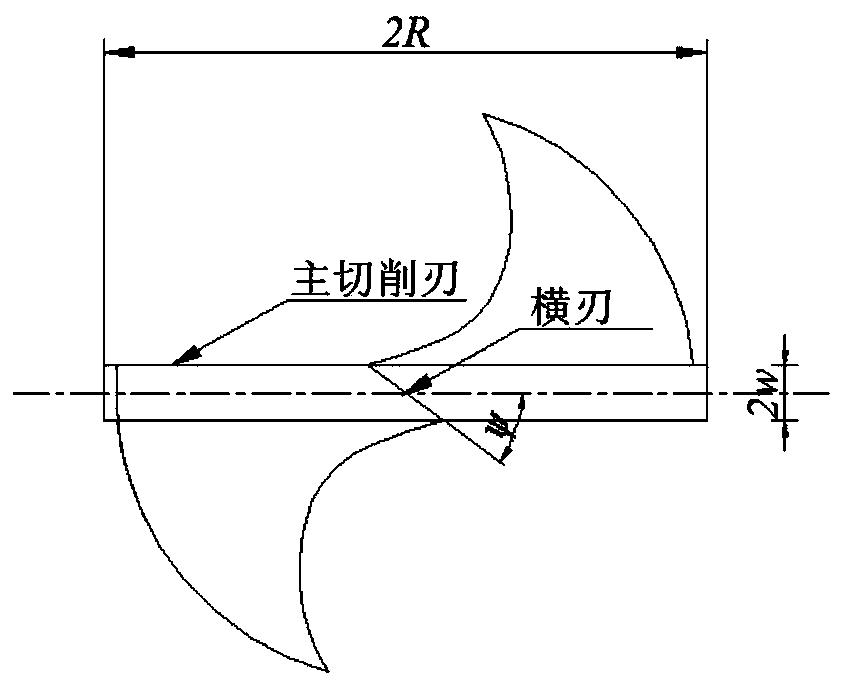

[0201] The experiment uses a CFRP material made of carbon fiber and epoxy resin orthogonally bidirectionally woven, and the elastic modulus E in the thickness direction 3 =3.32GPa, Poisson's ratio ν is 0.3, and the shear strengths perpendicular to the fiber direction and parallel to the fiber direction are 44.2MPa and 90MPa, respectively. The friction angle during drilling is set to 30 ° . The geometric parameters of the tool are shown in Table 1.

[0202] Table 1 Tool geometric parameters

[0203]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com