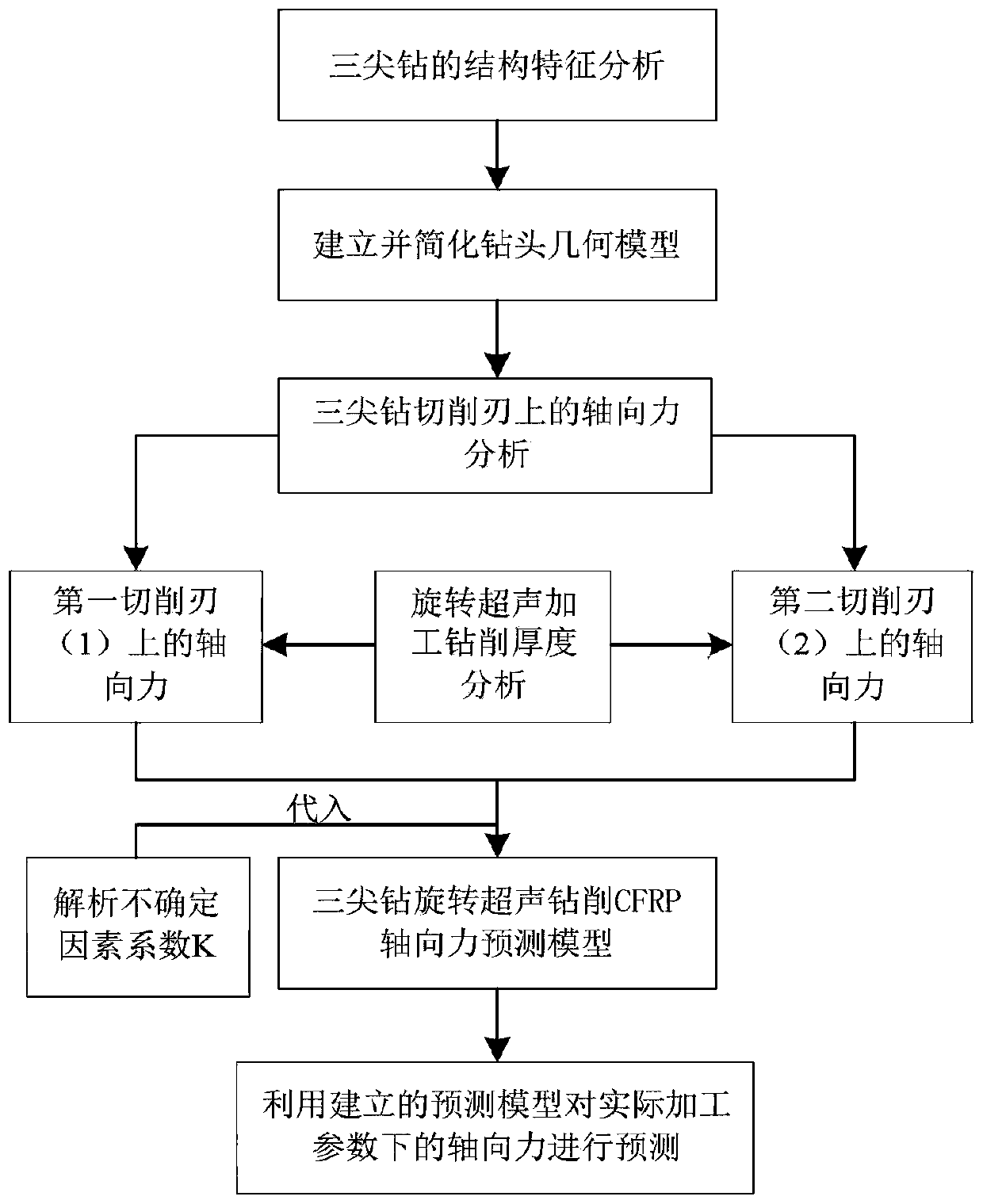

A method for predicting the axial force of carbon fiber composite materials by rotary ultrasonic drilling with three-tip drill

A technology of rotating ultrasonic and composite materials, applied in the direction of testing machinability, etc., can solve the problem of not using tri-point drills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

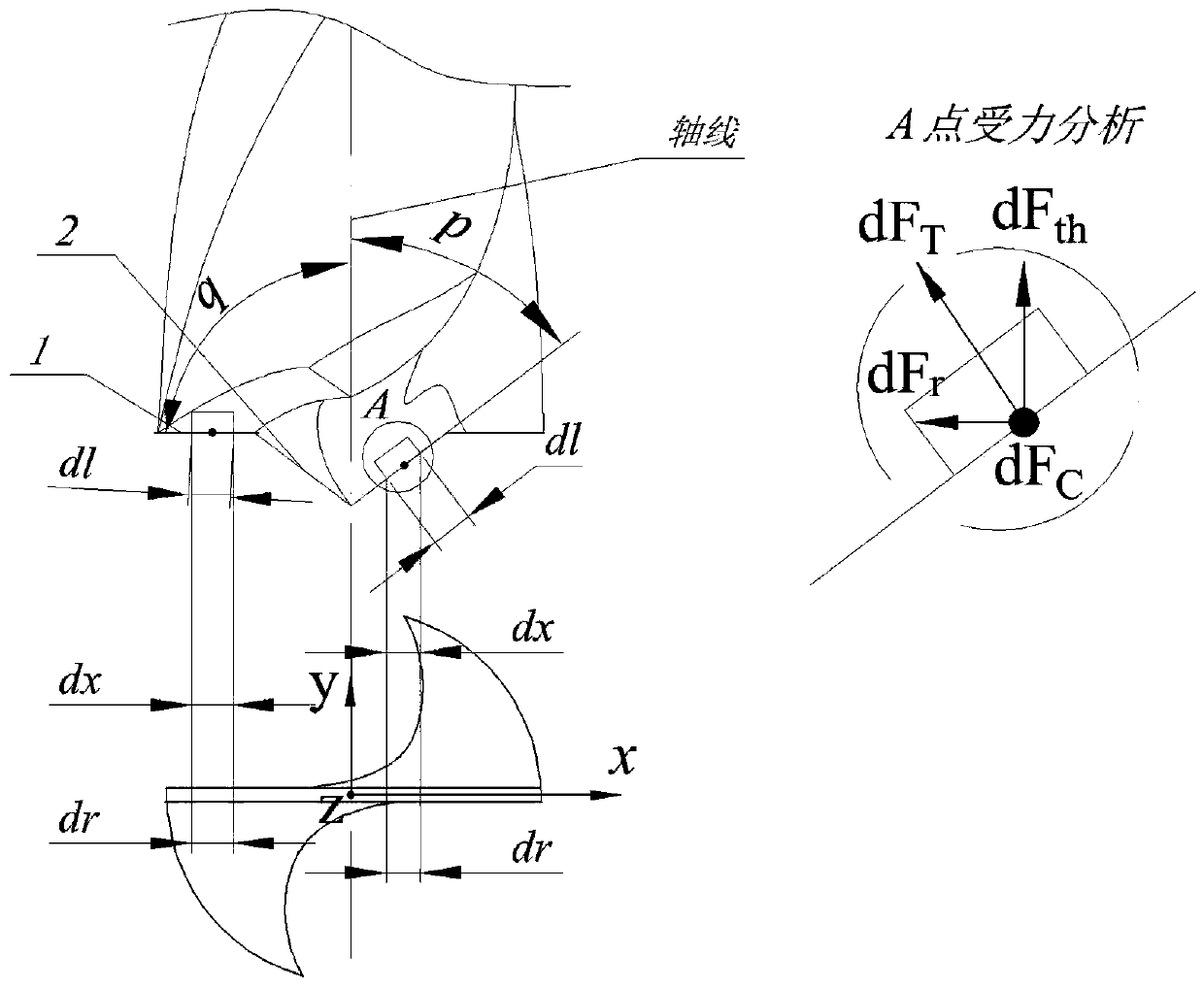

Method used

Image

Examples

Embodiment 1

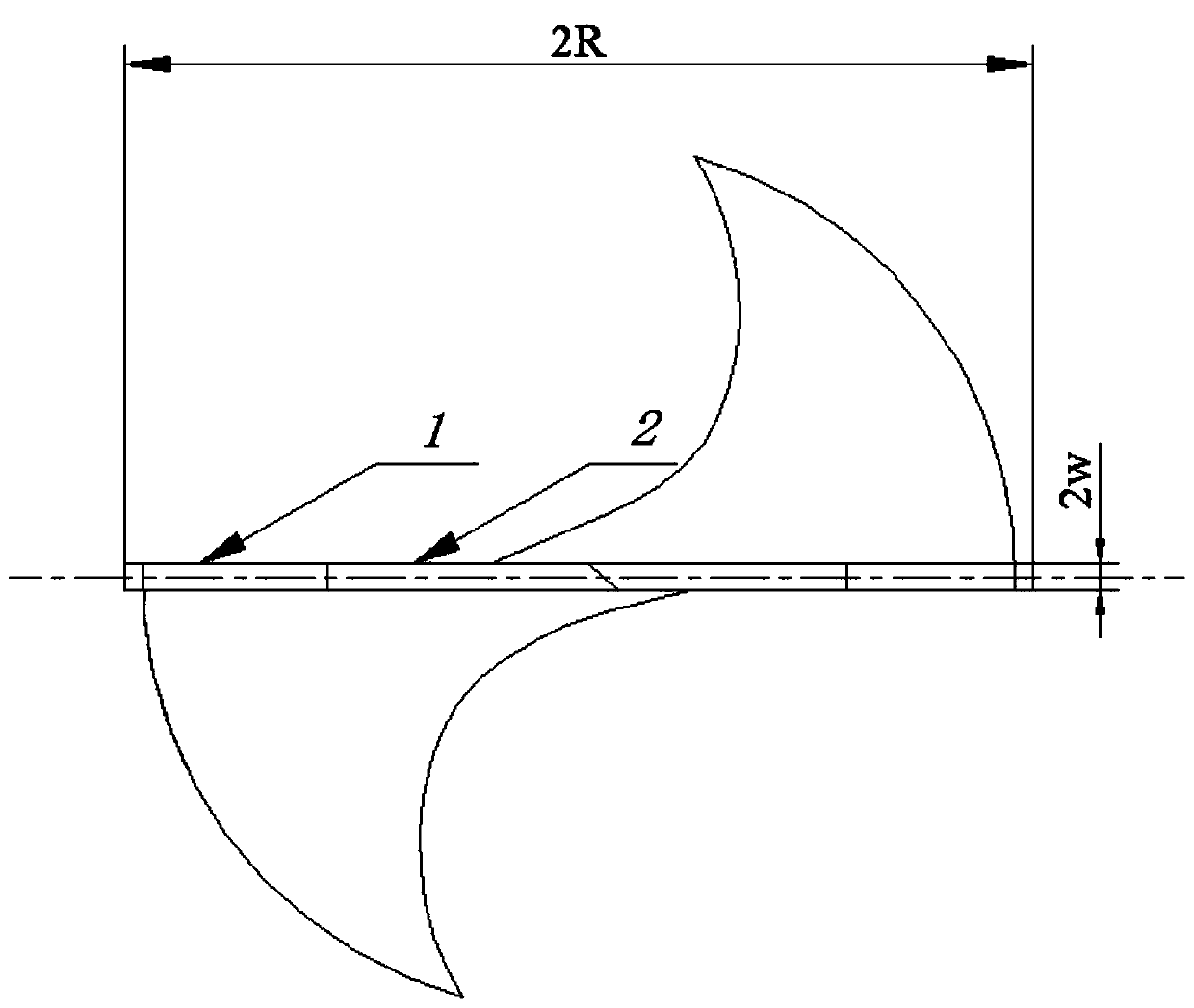

[0162] In the experiment, a CFRP material made of carbon fiber and epoxy resin orthogonal bidirectional weaving was used, and the shear strengths perpendicular to the fiber direction and parallel to the fiber direction were 44.2MPa and 90MPa, respectively. The friction angle during drilling is set to 30°. The geometric parameters of the tool are shown in Table 2.

[0163] Table 2 Geometric parameters of three-point drill

[0164]

[0165] Under the single factor experimental conditions, 12 groups of three-tip drill rotary ultrasonic drilling experiments were carried out. As mentioned above, the final prediction formula (21) can be used to predict the axial force under the drilling parameters. The comparison between the experimental value and the theoretical value of the drilling force is as Figure 5 shown. It can be seen from the comparison between the experimental value and the theoretical value that the change trend of the predicted axial force of rotary ultrasonic dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com