Insulator structure

A technology of insulators and ring structures, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve problems such as creepage phenomenon, and achieve the effect of preventing creepage phenomenon, significant effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

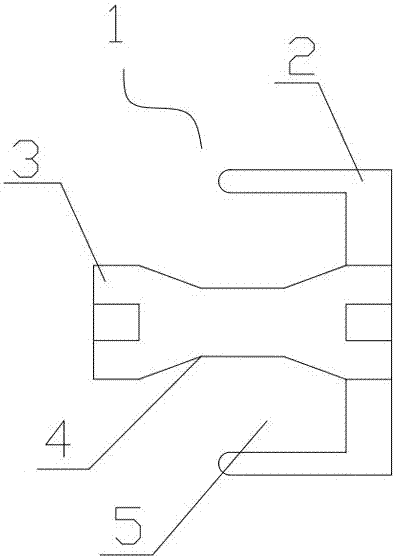

[0025] exist figure 1 , figure 2 In the described embodiment, an insulator structure includes: an insulator body 1, the insulator body 1 includes an insulator cover 2 and an insulator core 3; the insulator core 3 is arranged inside the insulator cover 2 and along the insulator cover 2 The center line of the center line extends out of the insulator cover 2, and the insulator core 3 is provided with an anti-creepage groove structure 4, and a cavity 5 is formed between the anti-creepage groove structure 4 and the inner wall of the insulator cover 2. The insulator cover body 2 and the insulator core body 3 are split structures.

[0026] The distance between the opening end of the insulator cover 2 and the anti-creepage groove structure 4 is set in an increasing structure.

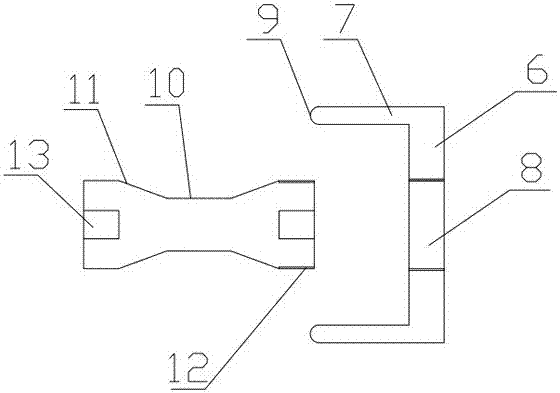

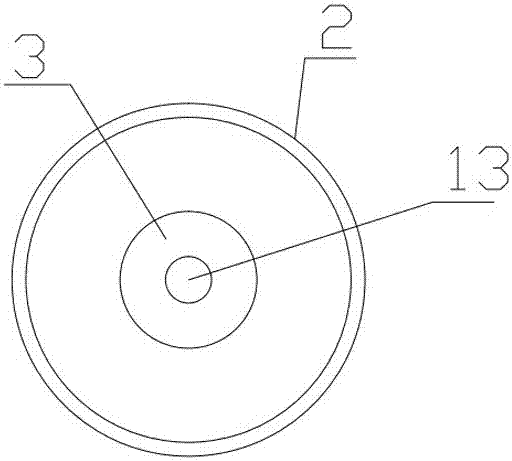

[0027] The insulator cover 2 includes a horizontal end surface 6 and a creepage cover 7 integrally provided. The horizontal end face 6 is a circular structure, and the creepage cover 7 is a ring structure (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com