Second-stage pedal sensing simulator and automotive brake pedal mechanism

A two-stage, simulator technology, applied in the direction of foot start device, etc., can solve the problems of high cost, difficult implementation, complex structure, etc., and achieve the effects of simple and reasonable structure, improved stability, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

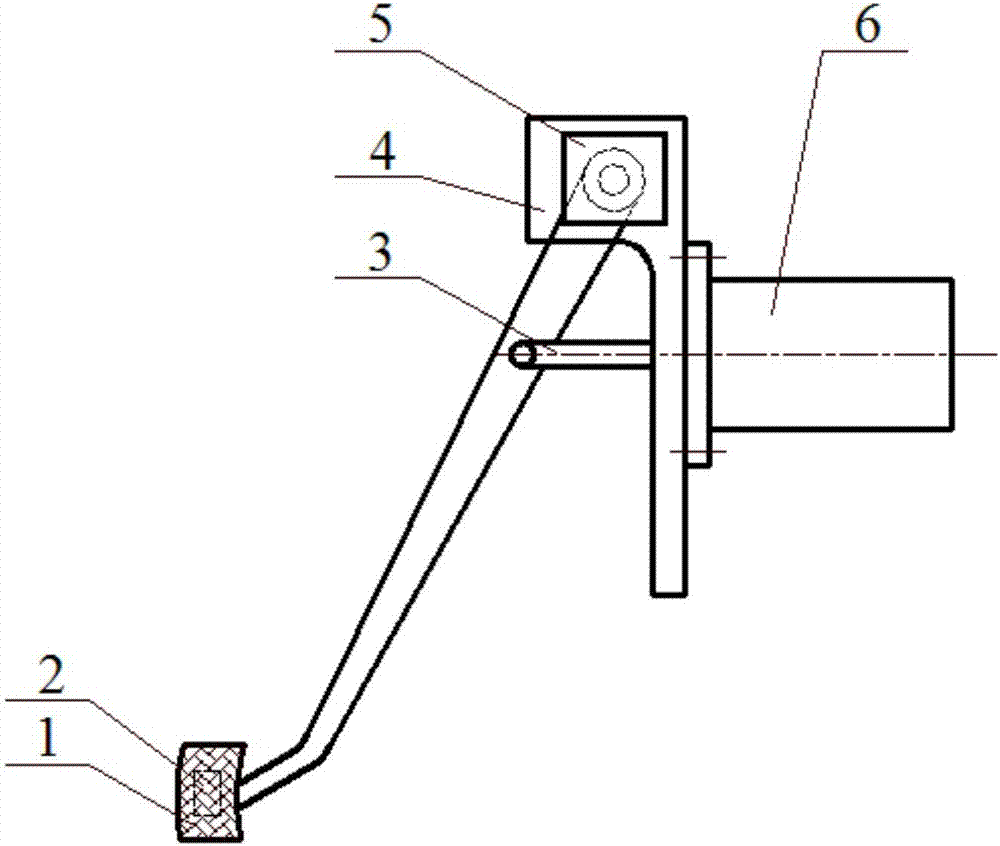

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In order to achieve the purpose of the present invention, a two-stage pedal feeling simulator is provided in one of the embodiments of the present invention, comprising:

[0039] shell;

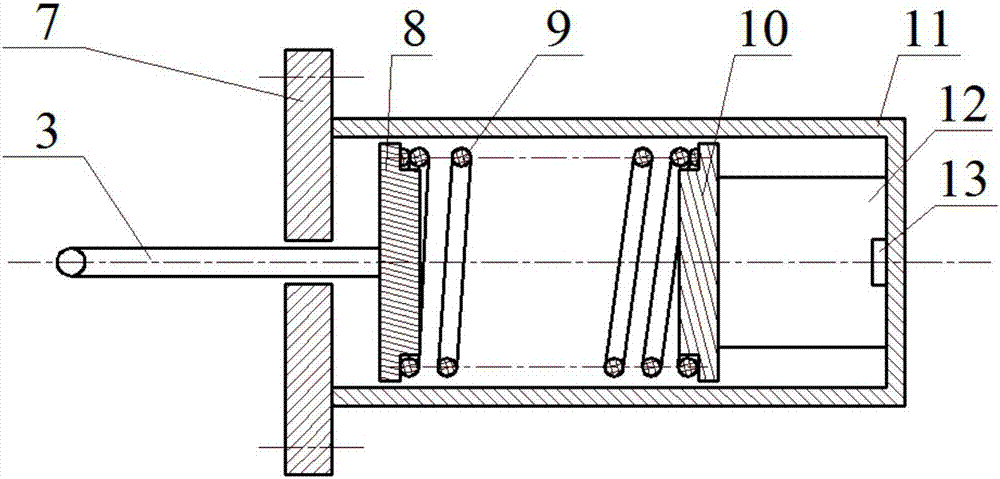

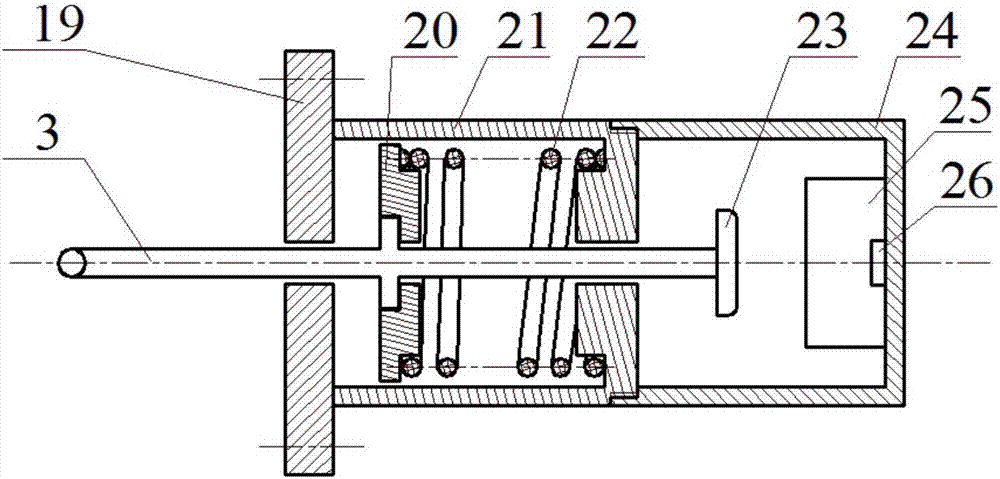

[0040] Two elastic mechanisms, including a first elastic assembly and a second elastic assembly, the first elastic assembly is arranged in the axial chamber of the casing along the axial movement of the casing, and the second elastic assembly is arranged on the rear end cover plate of the casing;

[0041] Brake push rod, the brake push rod moves along the axial direction of the shell at the axial center position of the shell and passes through the shell, the brake push rod is connected with the first elastic component, and is used to push the second elastic component after compression of the first elastic component Component deformation;

[0042]An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com