Aluminum alloy capillary and return pipe assembly with same

An aluminum alloy and capillary tube technology, applied in refrigeration and liquefaction, lighting and heating equipment, mechanical equipment, etc., can solve the problems of reducing the effective service life of refrigerators and electrochemical corrosion, so as to avoid the risk of electrochemical corrosion, prolong the service life, Effect of low price advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

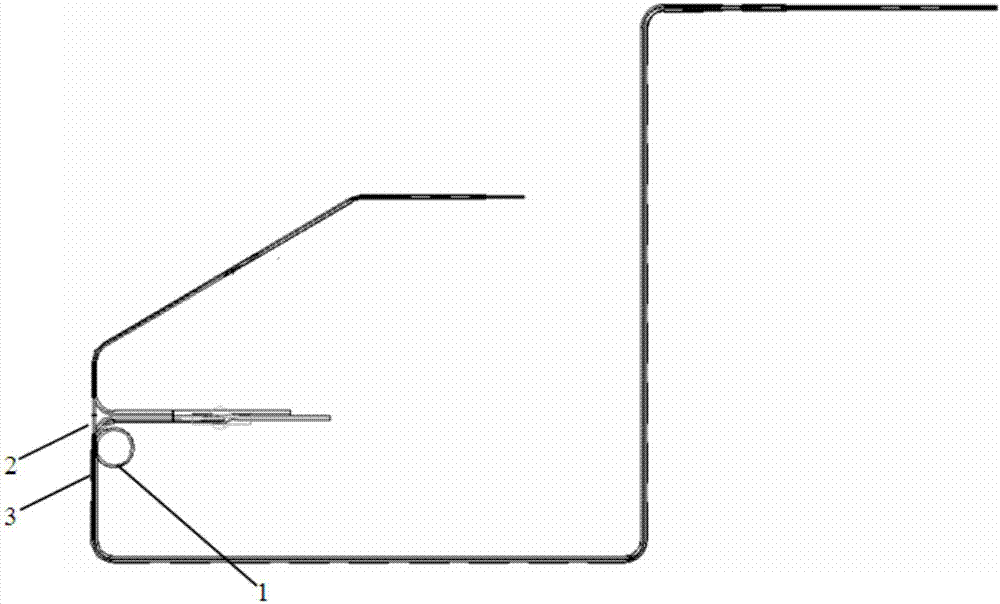

[0011] See attached figure 1 As shown, an aluminum alloy capillary tube 1 has an outer diameter of 1.8mm and a wall thickness of 0.6mm. It is made of 1060 aluminum tubes with a diameter of 5.9mm and a wall thickness of 0.9mm. The equipment is pulled out. One kind of air return pipe always becomes an aluminum alloy return air pipe 2 and the aluminum alloy capillary tube 1 which are wrapped by aluminum foil tape 3.

[0012] Compared with the copper capillary tube, the aluminum alloy capillary tube of the present invention has a low price advantage and a high-efficiency production method. The air return tube of the aluminum alloy capillary avoids the risk of electrochemical corrosion, and the air return tube is extended and the refrigerator using the return air tube life.

[0013] The above are only the preferred embodiments of the present invention, and are not intended to limit the present invention in other forms. Any person familiar with the profession may use the technical cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap