Probabilistic life prediction method for blade vibration fatigue

A vibration fatigue, probabilistic life technology, applied in geometric CAD, sustainable transportation, special data processing applications, etc., can solve the problem of low confidence level, distribution type assumptions and testing influence, and probability life prediction results without confidence interval estimation and other problems, to achieve the effect of high computational efficiency, computational accuracy and high confidence level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

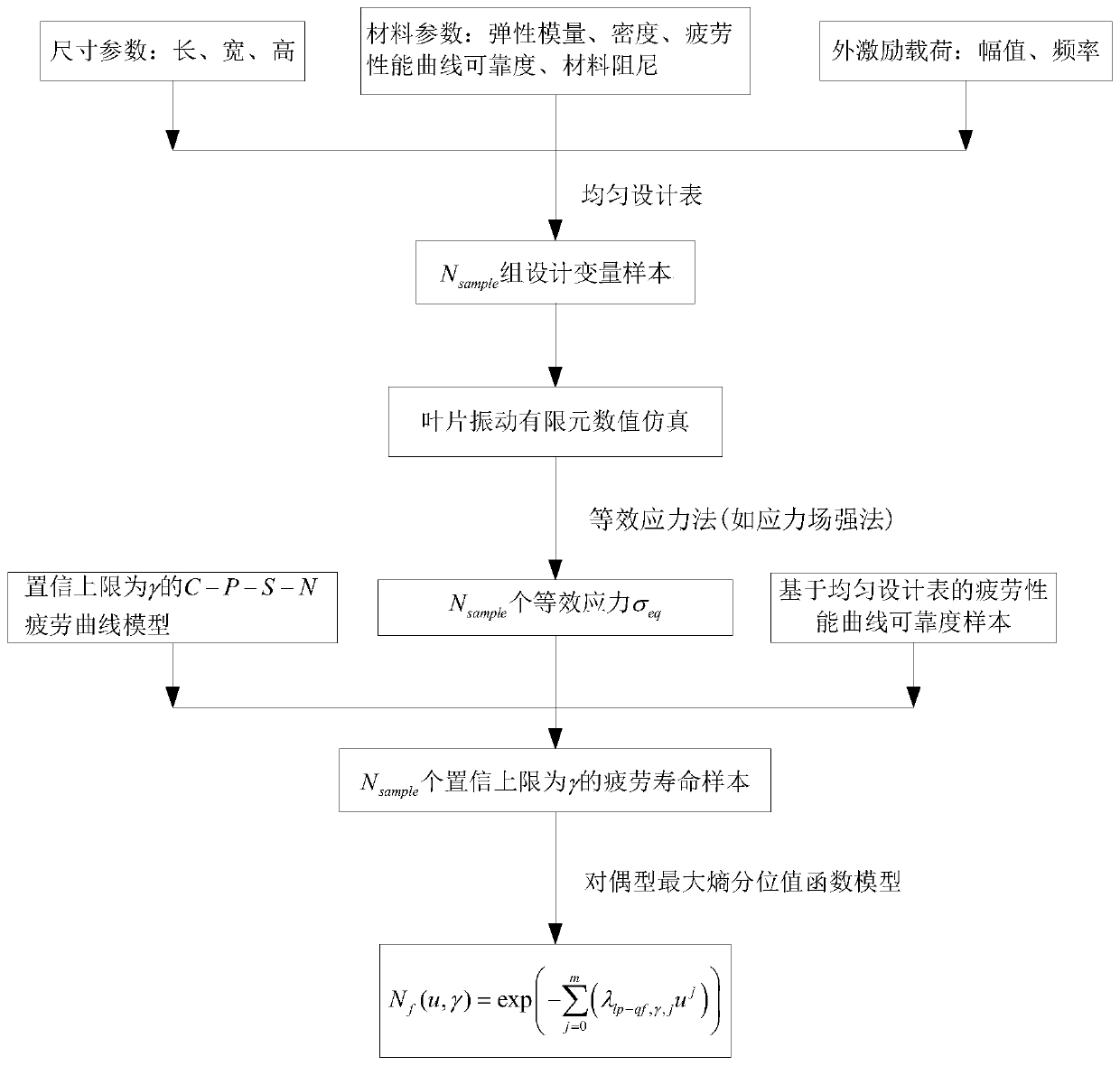

[0046] The blade vibration fatigue probabilistic life prediction model and method provided by the present invention comprise the following steps:

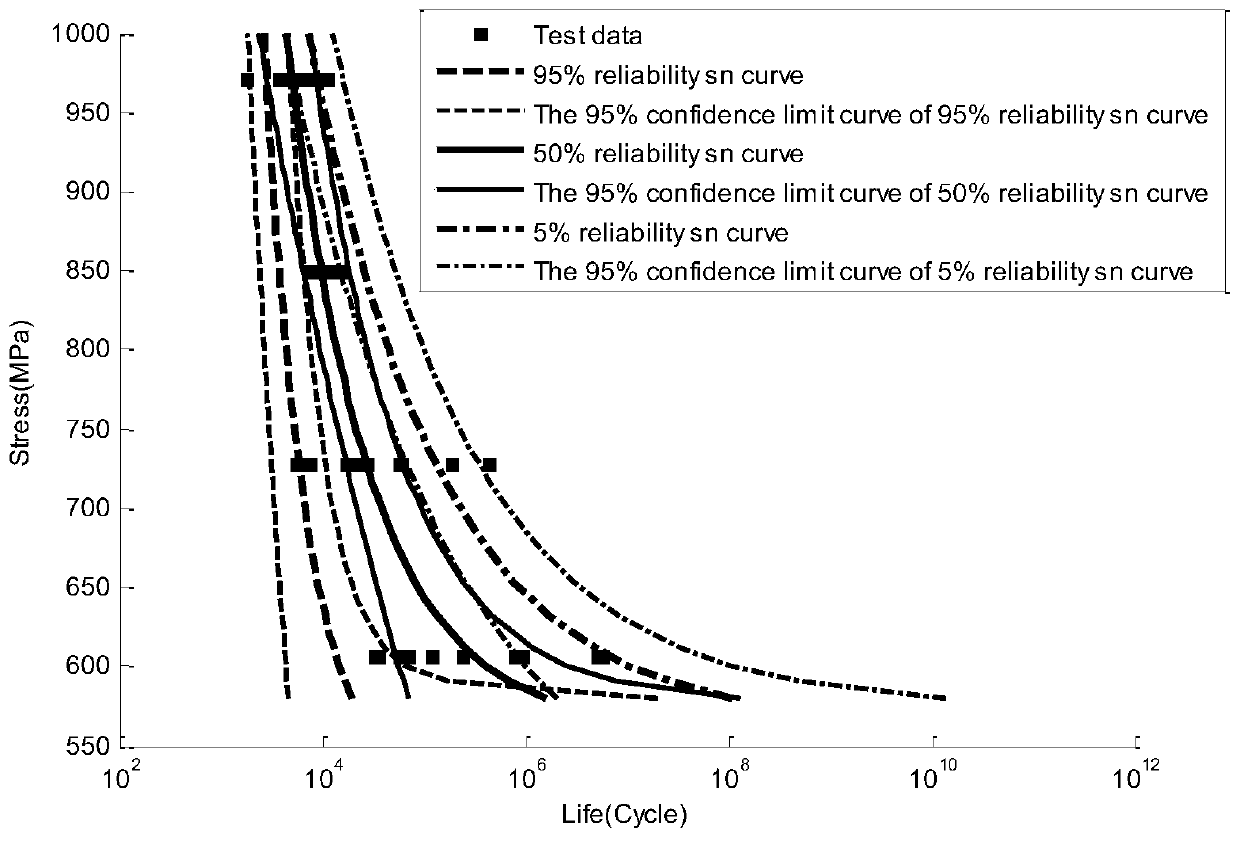

[0047] 1) Establish material C-P-S-N fatigue curve model

[0048] Due to the limited number of fatigue tests at the same stress level, the estimated probability distribution parameters (lognormal distribution parameters) are different from the parent distribution parameters. In order to improve the confidence level of fatigue life estimation, the dispersion coefficient method was introduced to establish the C-P-S-N fatigue curve model.

[0049] Assuming that the fatigue life sample group X of a certain stress level obeys the logarithmic normal distribution, then the random variable Y=lgX obeys the normal distribution N(μ Y ,σ Y ); define F- 1 (μ Y ,σ Y ,1-p) is the quantile value (F -1( ) is the inverse function of the cumulative distribution function of the random variable Y), then the fatigue life corresponding to the relia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com