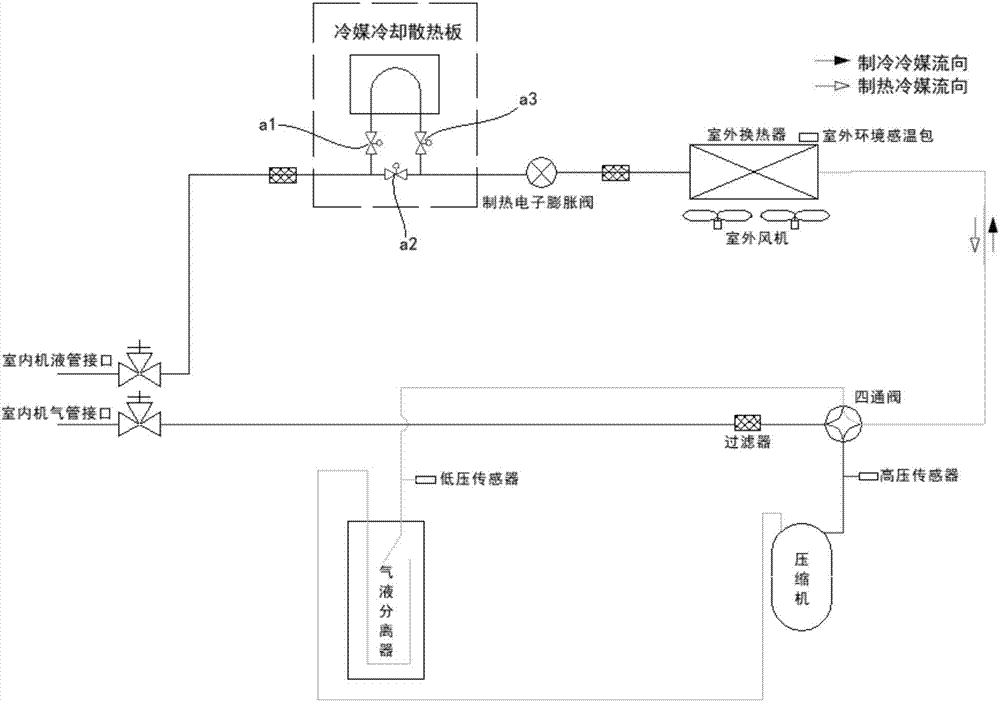

Refrigerant cooling main control board condensation preventing device and method and air conditioner unit

A refrigerant heat dissipation and main control board technology, applied in the field of air conditioners, can solve the problems of insignificant anti-condensation effect and slow temperature change process, and achieve the effect of remarkable anti-condensation effect, less refrigerant volume, and quick adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

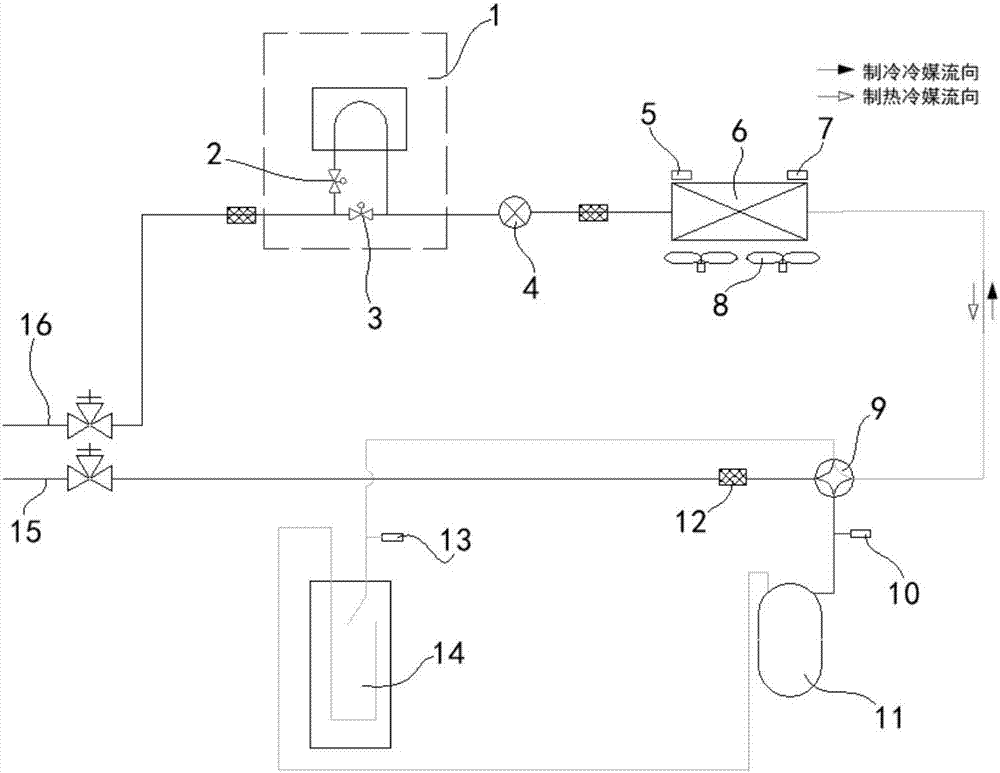

[0044] In the following, the first and second preferred embodiments of the anti-condensation device for the main control board of refrigerant heat dissipation are taken as examples to illustrate the first and second preferred implementation modes of the anti-condensation method for the main control board of refrigerant heat dissipation of the present invention as follows:

[0045] 1. The first preferred embodiment (such as Figure 4 shown, corresponding to figure 2 Shown embodiment) as shown in table 1:

[0046] Table 1

[0047]

[0048]

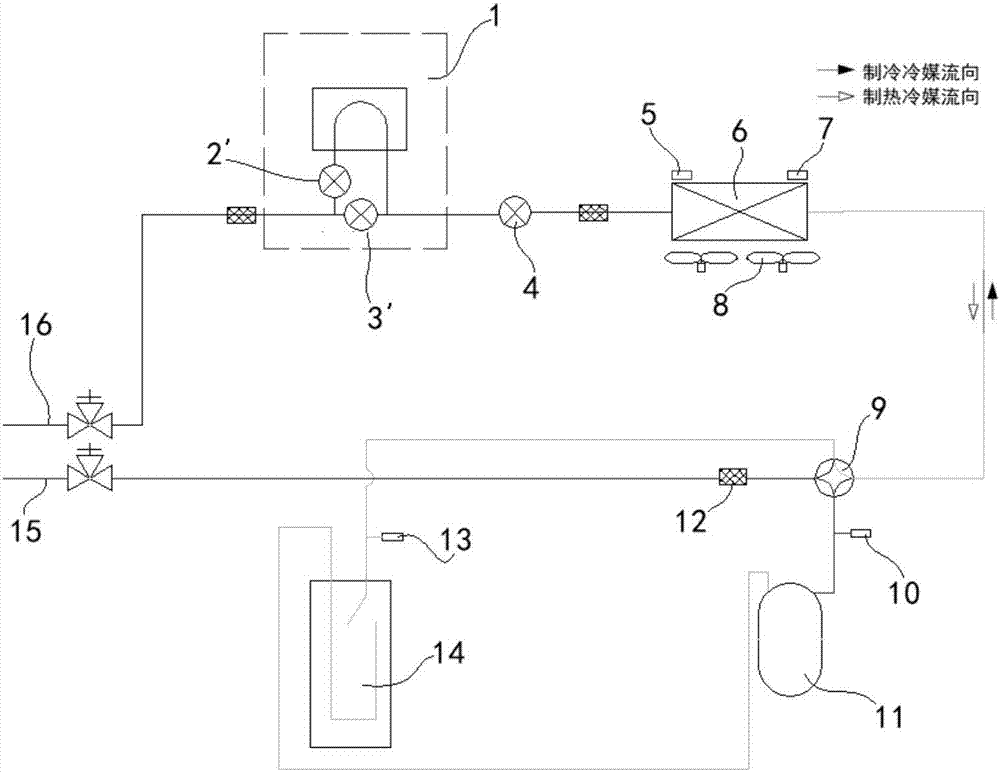

[0049] 2. The second preferred embodiment (such as Figure 5 shown, corresponding to image 3 Shown embodiment) as shown in table 2:

[0050] Table 2

[0051]

[0052] Among them, pls represents the measurement unit of the number of opening steps, T 1 Main control board temperature, T 0 For the corrected temperature value, T 2 is the dew point temperature; the corrected temperature value T0 is a configurable parameter, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com