Peripheral seam automatic sewing machine

A sewing machine and automatic sewing technology, which is applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve problems such as lowering the working efficiency of sewing machines, and achieve the effects of ensuring sewing efficiency, saving working time, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

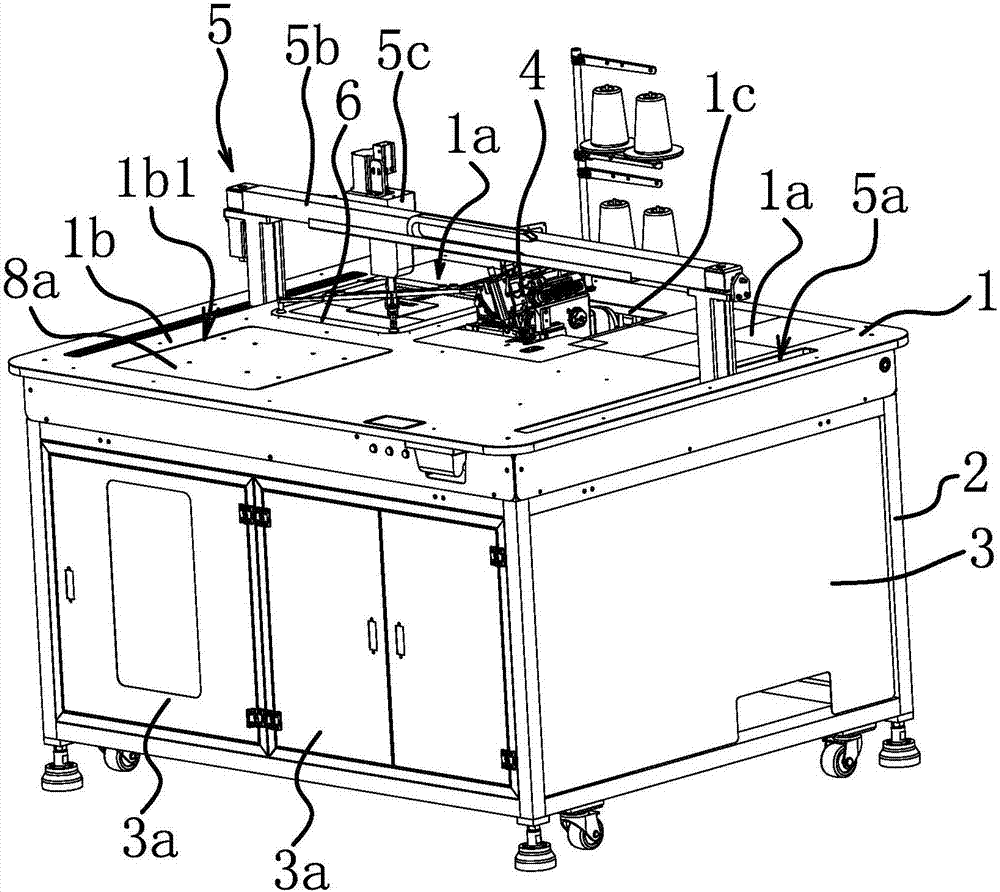

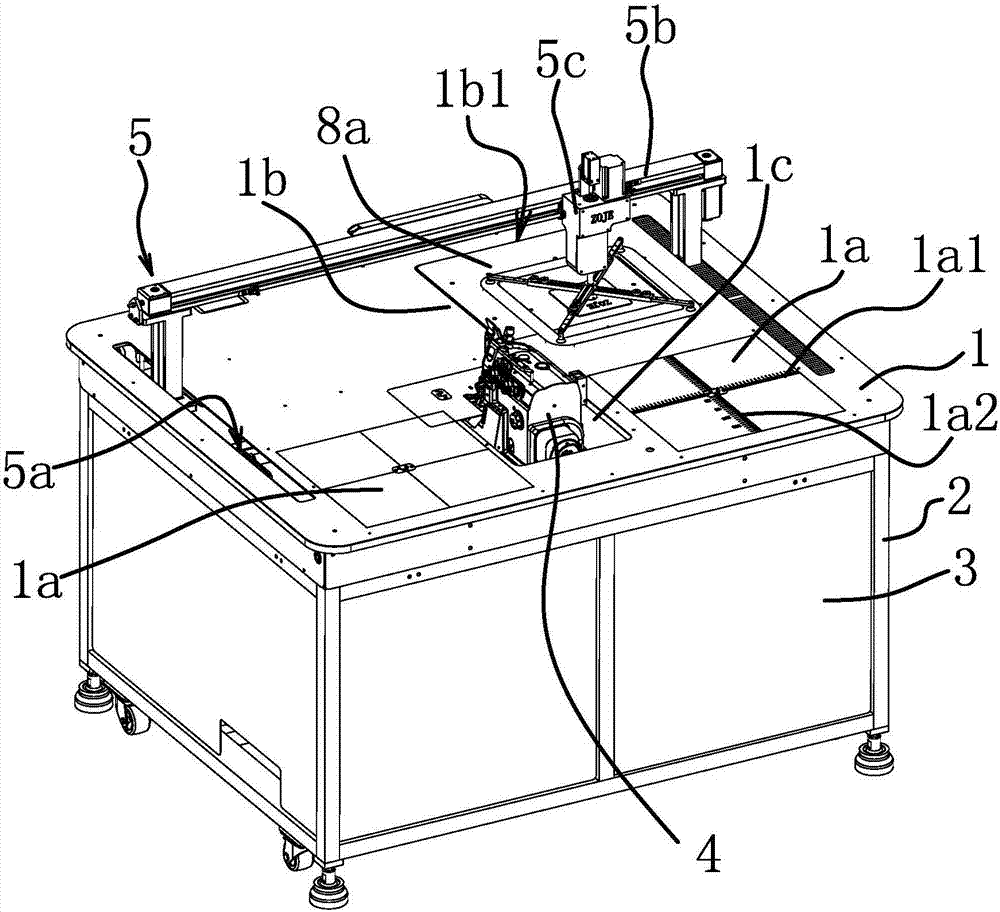

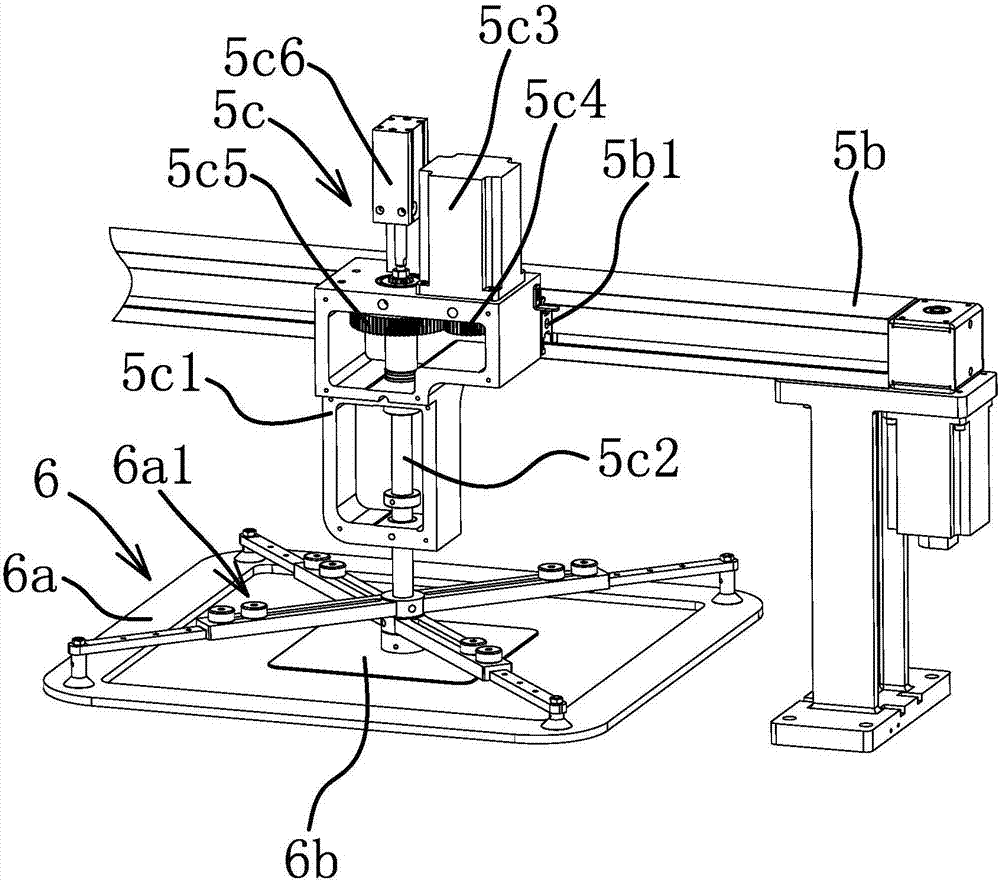

[0043] Such as figure 1 and figure 2 As shown, a peripheral sewing automatic sewing machine is used for sewing the peripheral of sewing materials, including an electric control system and a mechanical system. The mechanical system includes a platen 1 , a frame 2 is arranged under the platen 1 , and the platen 1 is fixed on the frame 2 . The deck 1 generally includes a deck 1 body and a deck 1 surface fixed on the deck 1 body. The upper surface of the deck 1 is a smooth metal surface, and the deck 1 is generally made of stainless steel, or it can be Made of aluminum alloy material. The four corners of the lower end of the frame 2 are provided with liftable feet, and the sides of each foot are correspondingly provided with casters, and the casters are hinged on the frame 2, and the setting of the feet and the casters is convenient for fixing and moving of the sewing machine. The frame 2 is provided with an outer cover 3 fixed with the frame 2, the outer cover 3 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com