Bypass type outer guiding gas injection valve with floating valve seat

A technology of gas injection valve and floating valve seat, which is used in engine components, combustion engines, machines/engines, etc., can solve problems such as affecting the normal use of the engine, engine performance, reverse leakage of the injection valve, insufficient gas supply, etc., to avoid Air flow interference, the effect of realizing the stability of the gas path, ensuring reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

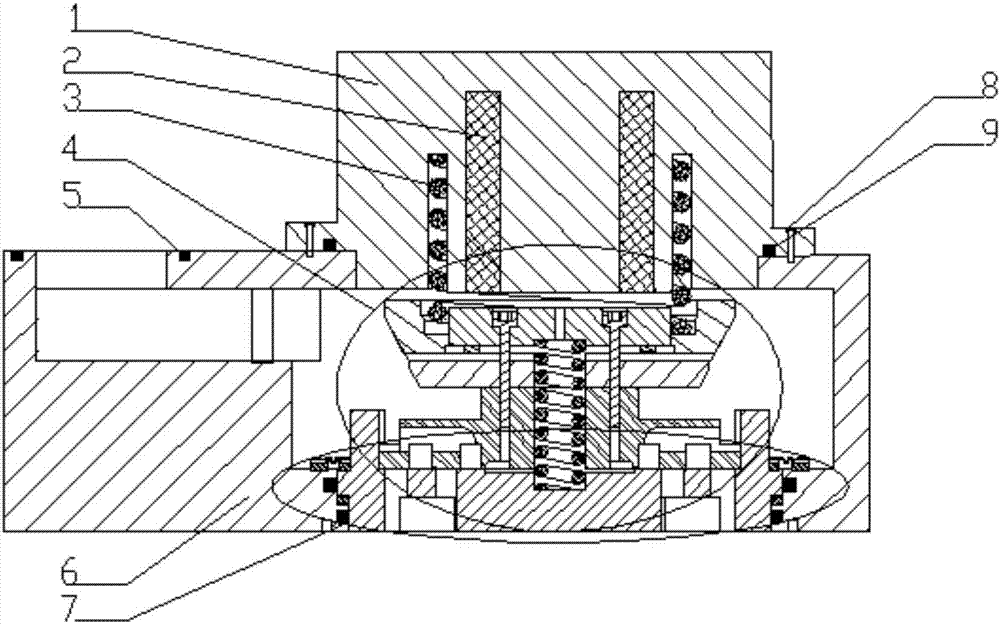

[0018] combine Figure 1-7 , figure 1 It is a schematic diagram of the overall structure of the bypass type externally guided gas injection valve with a floating valve seat of the present invention, which is mainly composed of an electromagnet 1, a coil 2, a return spring 3, a valve core assembly 5, a valve body 6 and a floating valve seat 7. The electromagnet 1 is fixed on the valve body 6 by the fixing bolt 8, the coil 2 is wound in the ring groove inside the electromagnet 1, and the valve core assembly 5 and the floating valve seat 7 are arranged sequentially under the electromagnet 1 from top to bottom.

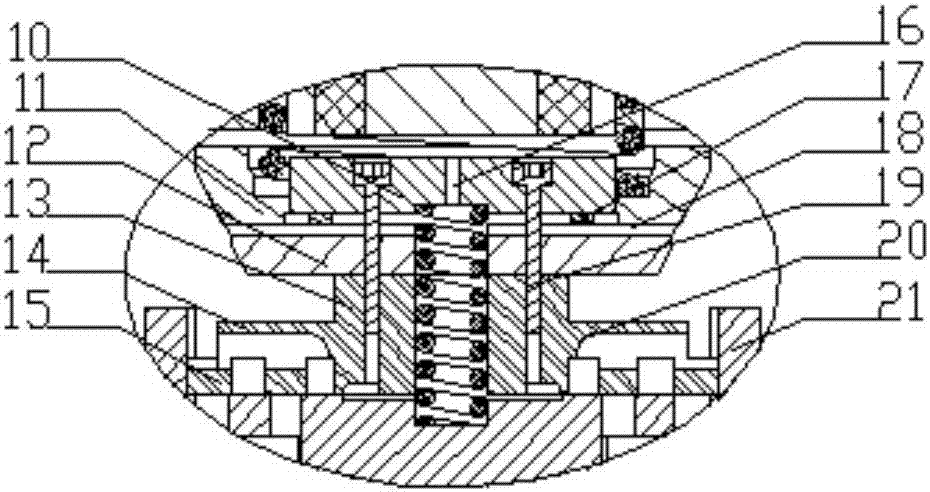

[0019] like figure 2 As shown, a valve core assembly 5 of a bypass type externally guided gas injection valve with a floating valve seat is mainly composed of an armature 10, a spring seat 11, a fastening bolt 19, a gasket 17, a bottom plate 12 and a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com