Direct-pass inner guide gas spraying valve with floating valve base

A technology of gas injection valve and floating valve seat, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as reverse leakage of injection valves, increase flow coefficient, increase intake air volume, and reduce flow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings:

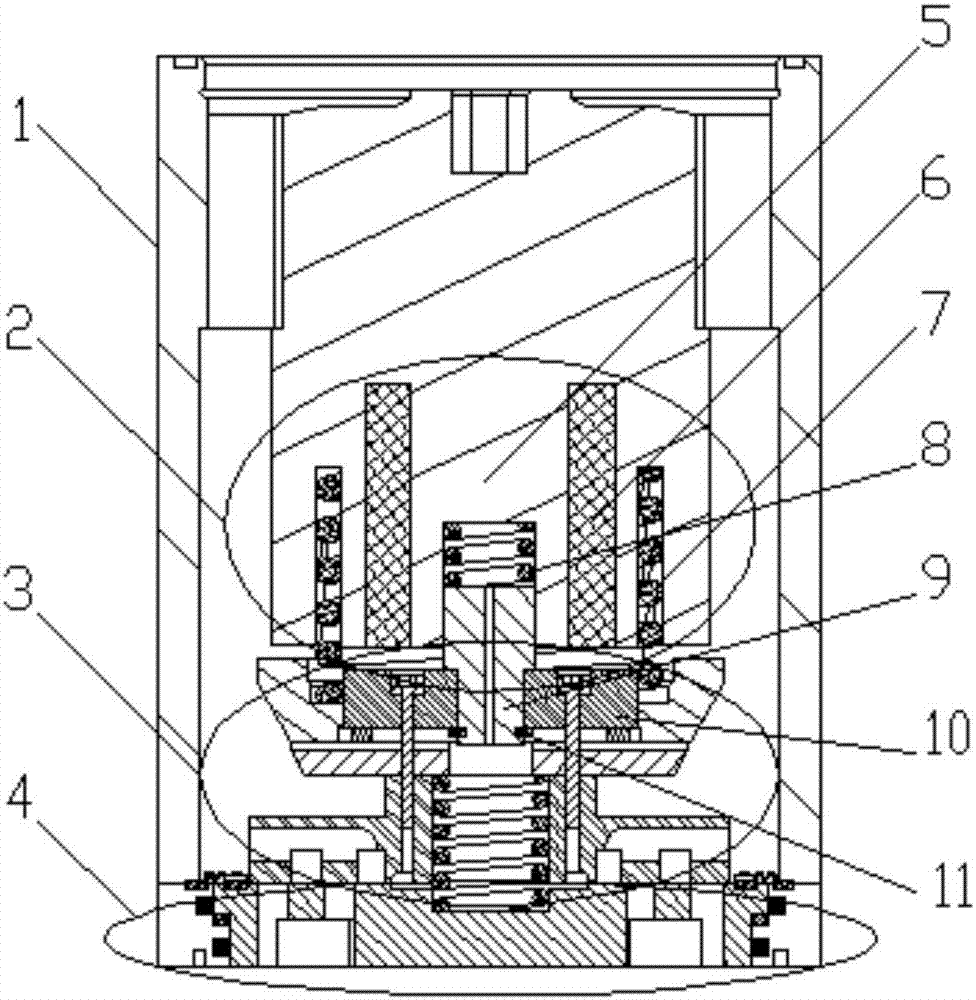

[0018] combine Figure 1-7 , figure 1 It is a schematic diagram of the overall structure of the straight-through inner-guided gas injection valve with a floating valve seat of the present invention, including four major parts: a valve body 1, an electromagnet 2, a valve core assembly 3, and a floating valve seat 4. The electromagnet 2 is connected with the valve body 1 through the upper thread. The electromagnet 2 is mainly composed of an iron core 5 and a coil 6 . There are annular grooves on both sides of the iron core 5 for arranging the main return spring 7, a straight groove with a certain depth is formed in the center of the iron core 5, and the guide pins 9 between the iron core 5 and the armature 10 are arranged inside the straight groove.

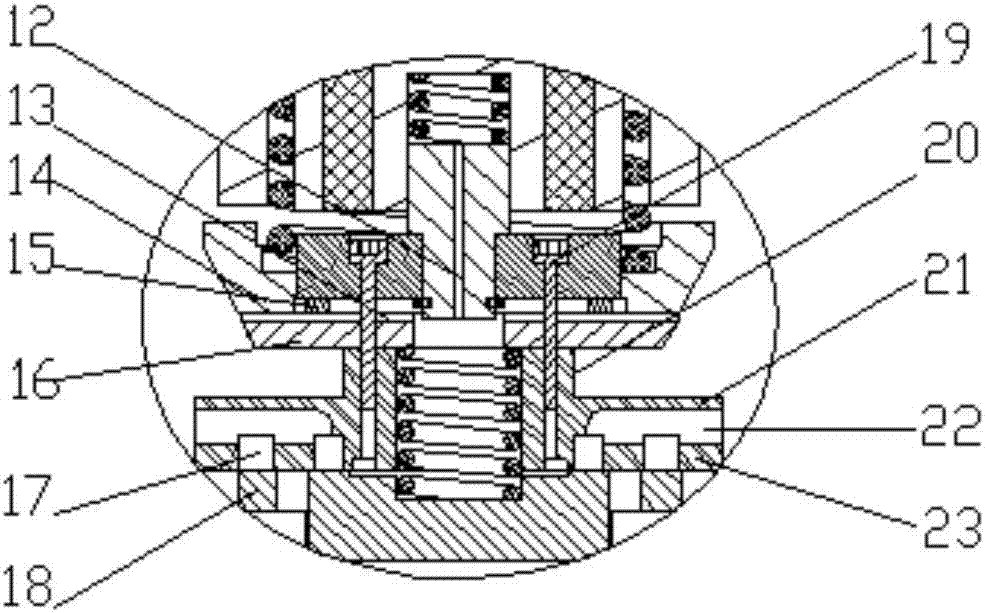

[0019] figure 2 The valve core assembly 3 is mainly composed of a guide pin 9 , an armature 10 , a spring sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com