A Noise Removal Method for NC Cutting Toolpath Data

A cutting tool, cutting tool technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problem that data characteristics cannot be further defined, data analysis and data mining, data mining and data analysis results are not satisfactory, data proportion It can reduce the quality risk, realize the early warning of failure, and meet the effect of denoising requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawings and examples.

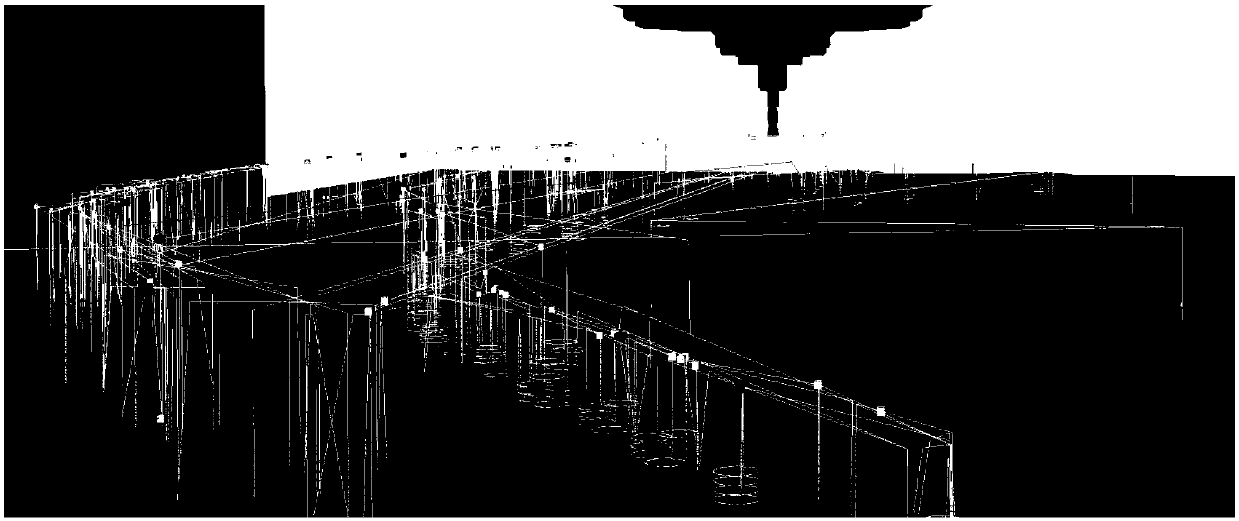

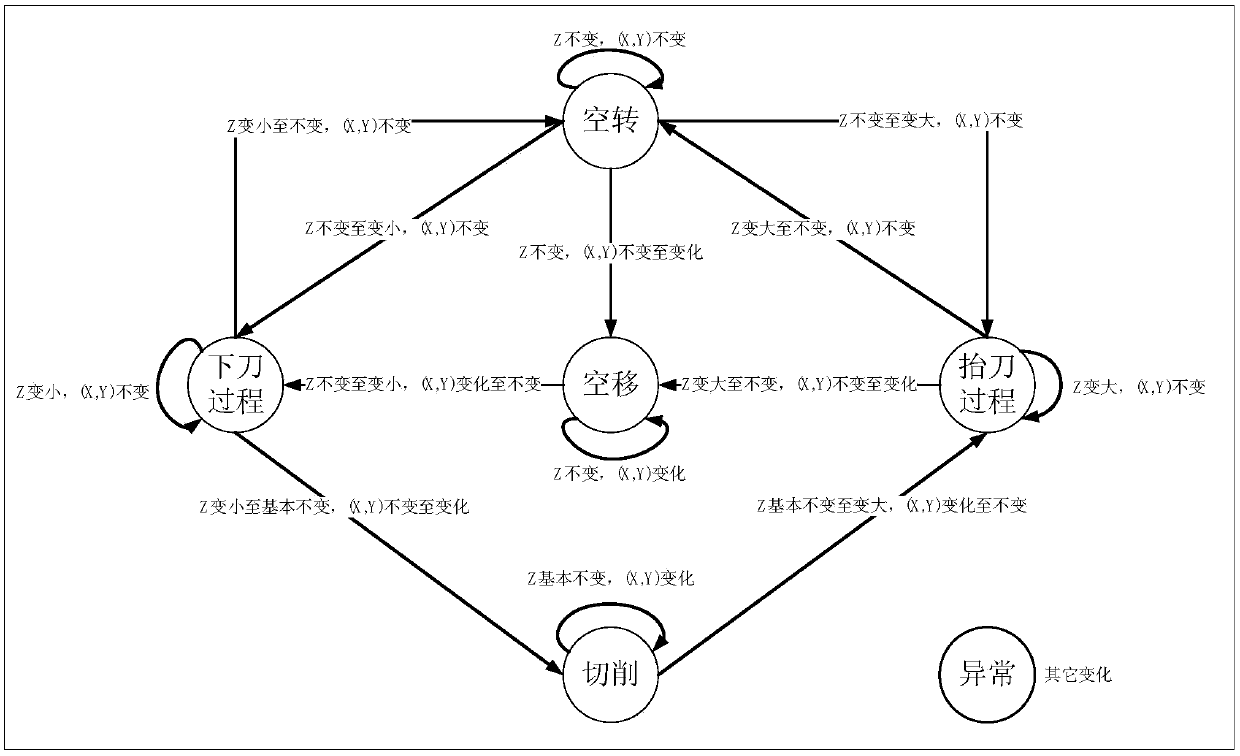

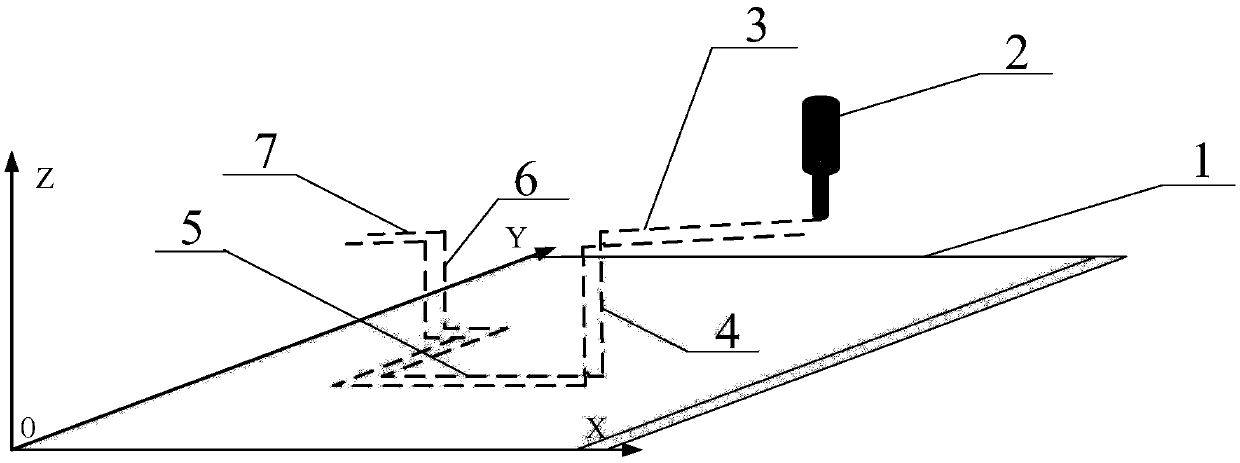

[0042] See figure 1 , figure 2 and image 3 :

[0043] For the part of the tool track generated during the cutting process of CNC machining, the upper surface 1 of the workpiece is used as the machining reference plane, that is, the (X, Y, 0) reference coordinate plane; the CNC cutting tool 2 moves during the machining process to form the tool track ( image 3 middle dotted line); under normal processing conditions, the tool is in an idling state at the beginning of processing (the three-dimensional coordinates of the tool do not change when the tool is idling, and its tool path is a fixed point), and then the tool enters the process of idling and cutting , Cutting, tool lifting process, idle state, the tool returns to the idling state at the end of the processing, and sequentially generates idle moving tool track 3, tool lowering process tool track 4, cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com