Fully automatic external scraper filter

An external, fully automatic technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of large wear and tear of the filter screen and scraper, and shorten the service life of the filter screen and scraper, so as to achieve thorough cleaning and increased use. longevity, effect of good filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

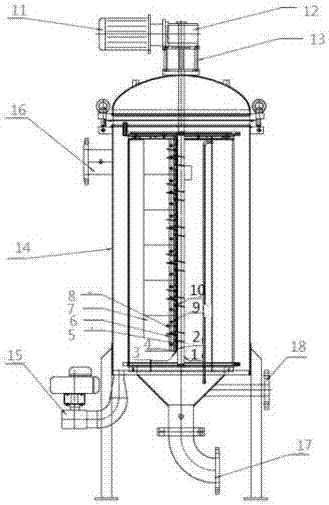

[0018] Such as figure 1 As shown, the present invention provides a fully automatic external scraper filter, including a motor 11 and a cylinder 14. The interior of the cylinder 14 is equipped with a main shaft 1, a fixed sleeve 2 and a rotating sleeve 5, and the top of the cylinder 14 is decelerated The machine support 13 is equipped with a reducer 12, the upper end of the cylinder 14 is provided with a feed port 16, the bottom of the cylinder 14 is provided with a discharge port 17, and one side of the lower end of the cylinder 14 is equipped with a blowdown valve 15, and the motor 11 passes through the deceleration. The machine 12 is in transmission connection with the main shaft 1, and the main shaft 1 is equipped with a plurality of evenly distributed scrapers 7 through the first scraper clamping plate 6 and the second scraper clamping plate 8.

[0019] There are 3 groups of scrapers 7 and they are evenly distributed at 120 degrees, and each group is equipped with 6 scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com