Objective table for clamping test specimen

A stage and clamping technology, applied in clamps, manufacturing tools, etc., can solve the problems of wasting space, increasing the space area of the stage, etc., and achieve the effect of reducing the space area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

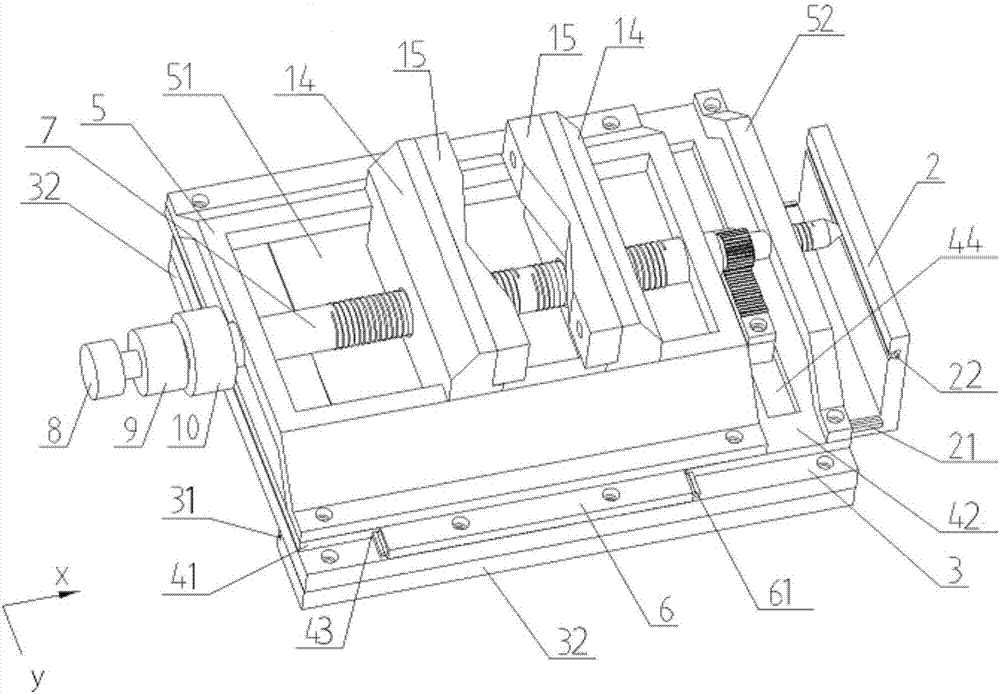

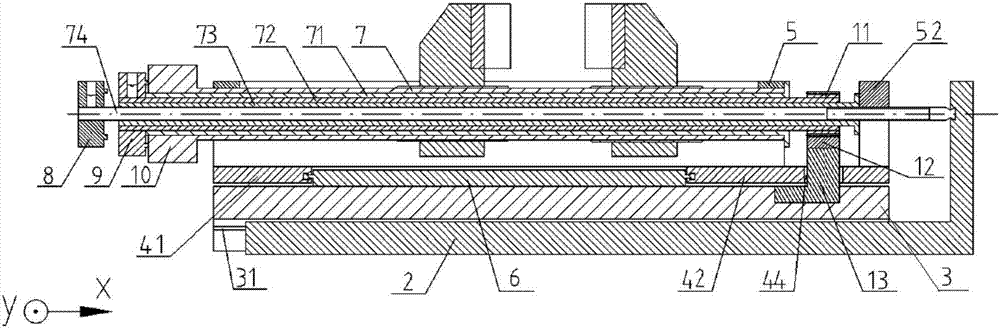

[0022] like Figure 1-2 As shown, the stage for clamping samples includes: a base 2, a first moving part 3, a second moving part, a sample holding bracket 5, a sub-support 52, a second moving part guide 6, an outer shaft 7. Intermediate shaft 72, inner shaft 74, V-shaped block bracket 14, V-shaped block 15;

[0023] Wherein, the side of the base 2 is L-shaped, including a horizontal plane and a vertical plane; on both sides of the top surface of the horizontal plane of the base 2, an X-axis guiding linear protrusion 21 extending along the X-axis direction is respectively provided. A Y-axis guide groove 22 extending along the Y-axis direction is provided at the top end of the inner surface of the vertical surface of 2;

[0024] The main body of the first moving part 3 is plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com