Bulbous bow and hull

A bulbous bow and hull technology, applied in the field of ship design, can solve the problems of the bulbous bow’s ability to reduce wave-making resistance, not being strong, and increasing ship operating costs, so as to reduce propulsion power, reduce wave-making resistance, and reduce operating costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

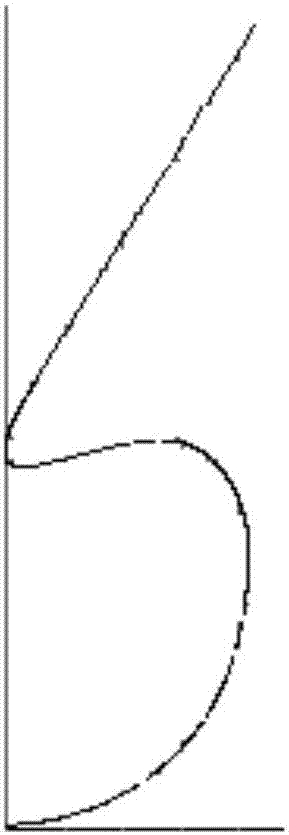

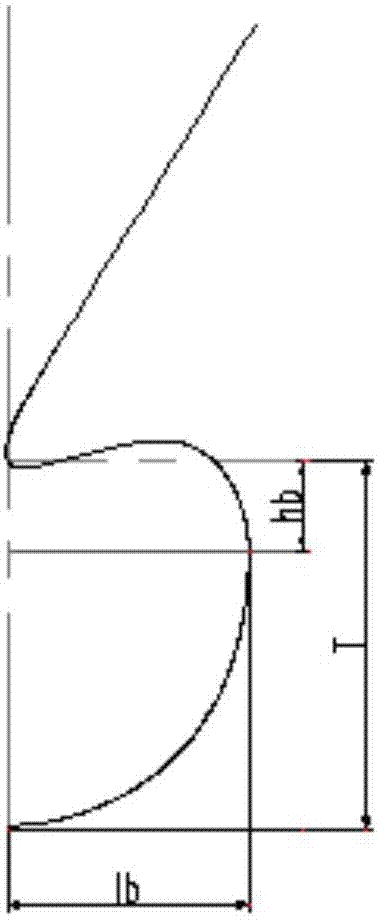

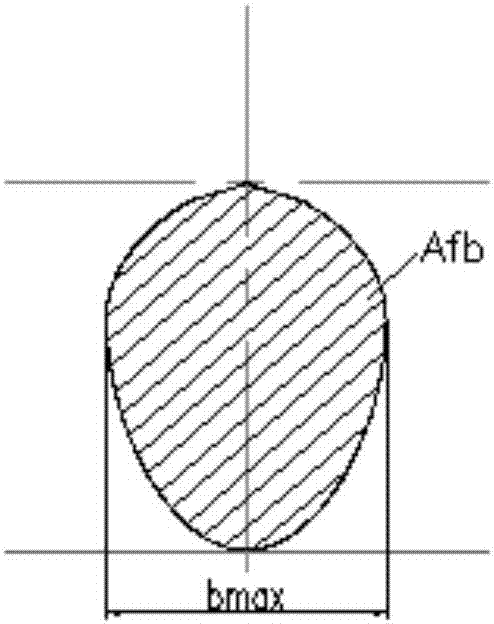

[0025] This embodiment provides a bulbous bow, such as figure 1 As shown, the height of the first end of the bulbous bow is greater than the height of the second end of the bulbous bow, so that the first end of the bulbous bow is upturned; and the height of the first end of the bulbous bow is higher than The full load line of the hull, so that when part of the bulbous bow is immersed in water, the additional resistance and wave breaking resistance are small.

[0026] see figure 1 , the upper surface of the bulbous bow is an arc surface, and the arc surface is concave from the first end of the bulbous bow to the second end of the bulbous bow, and the second end of the bulbous bow is in contact with the hull connected with the forward perpendicular line of the bow, so that the upper surface of the bulbous bow can form a diversion surface, so that the water flow to the stem of the hull has a downward component, which is more conducive to reducing the wave-making resistance of th...

Embodiment 2

[0035] Corresponding to Embodiment 1, this embodiment provides a hull, the hull is preferably a medium-speed ship, and the Fourier number Fr of the hull is 0.2-0.3. v is the speed of the ship, L is the length of the ship, and the bow of the hull is equipped with the bulbous bow provided by Embodiment 1, such as figure 1 As shown, the height of the first end of the bulbous bow is greater than the height of the second end of the bulbous bow; making the first end of the bulbous bow upturned; and the height of the first end of the bulbous bow is higher than The full load line of the hull, so that when part of the bulbous bow is immersed in water, the additional resistance and wave breaking resistance are small.

[0036] see figure 1 , the upper surface of the bulbous bow is an arc surface, and the arc surface is concave from the first end of the bulbous bow to the second end of the bulbous bow, and the second end of the bulbous bow is in contact with the hull connected with the...

Embodiment 3

[0045] In practical applications, the bulbous bow provided in Embodiment 1 can be applied to medium-speed ships, such as figure 1 As shown, the height of the first end of the bulbous bow is greater than the height of the second end of the bulbous bow; making the first end of the bulbous bow upturned; and the height of the first end of the bulbous bow is higher than The full load line of the hull, so that when part of the bulbous bow is immersed in water, the additional resistance and wave breaking resistance are small. In the present embodiment, the full load line of the hull is 6600WL.

[0046] see figure 1 , the upper surface of the bulbous bow is an arc surface, and the arc surface is concave from the first end of the bulbous bow to the second end of the bulbous bow, and the second end of the bulbous bow is in contact with the hull connected with the forward perpendicular line of the bow, so that the upper surface of the bulbous bow can form a diversion surface, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com