Pistons for hydraulic valves for camshaft phasers and hydraulic valves for camshaft phasers for camshafts

A technology of phase adjuster and camshaft, which is applied in the field of hydraulic valves and can solve problems such as high cost and high assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

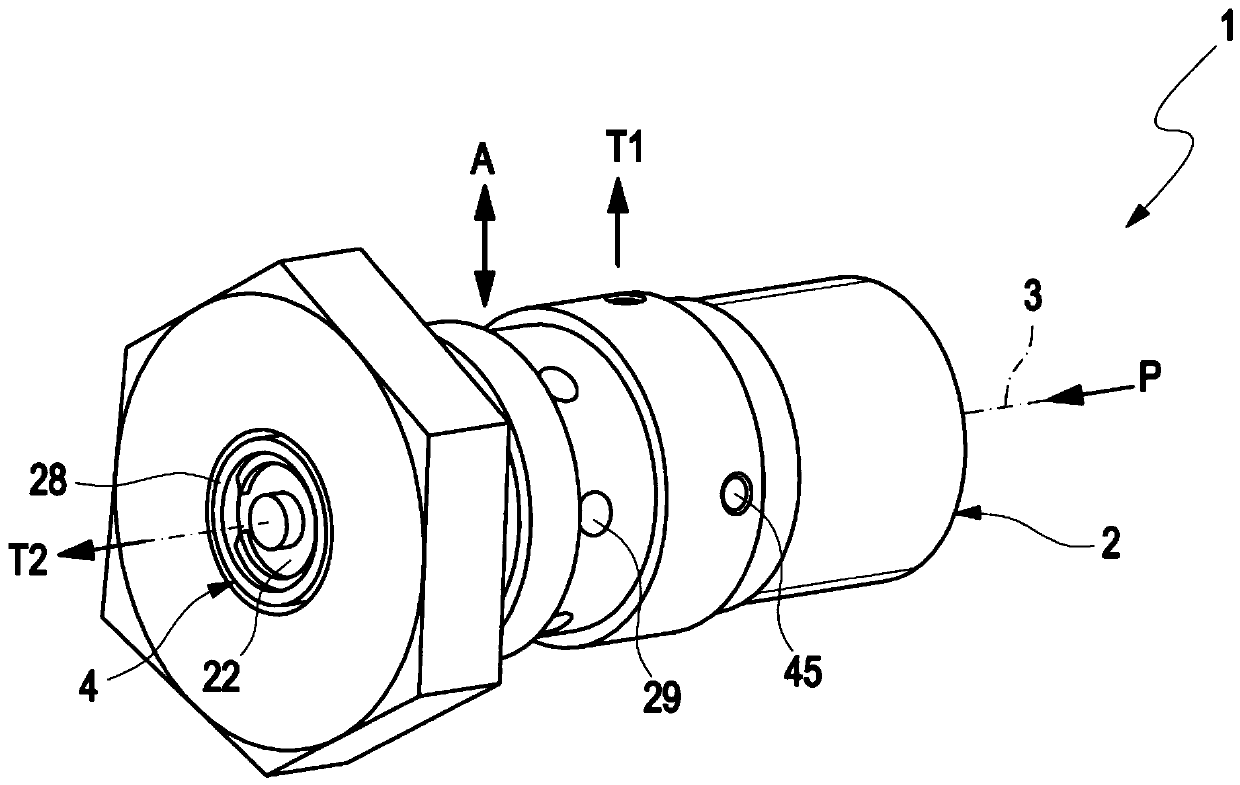

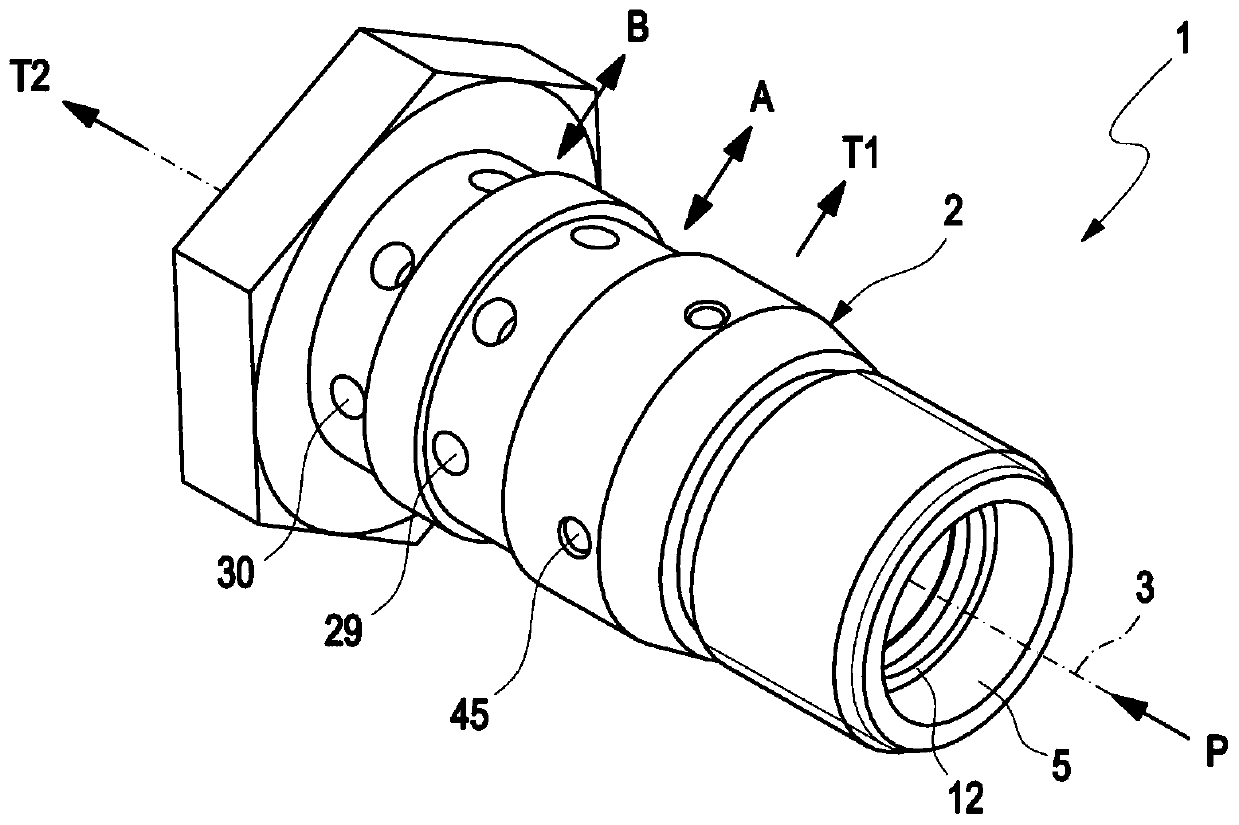

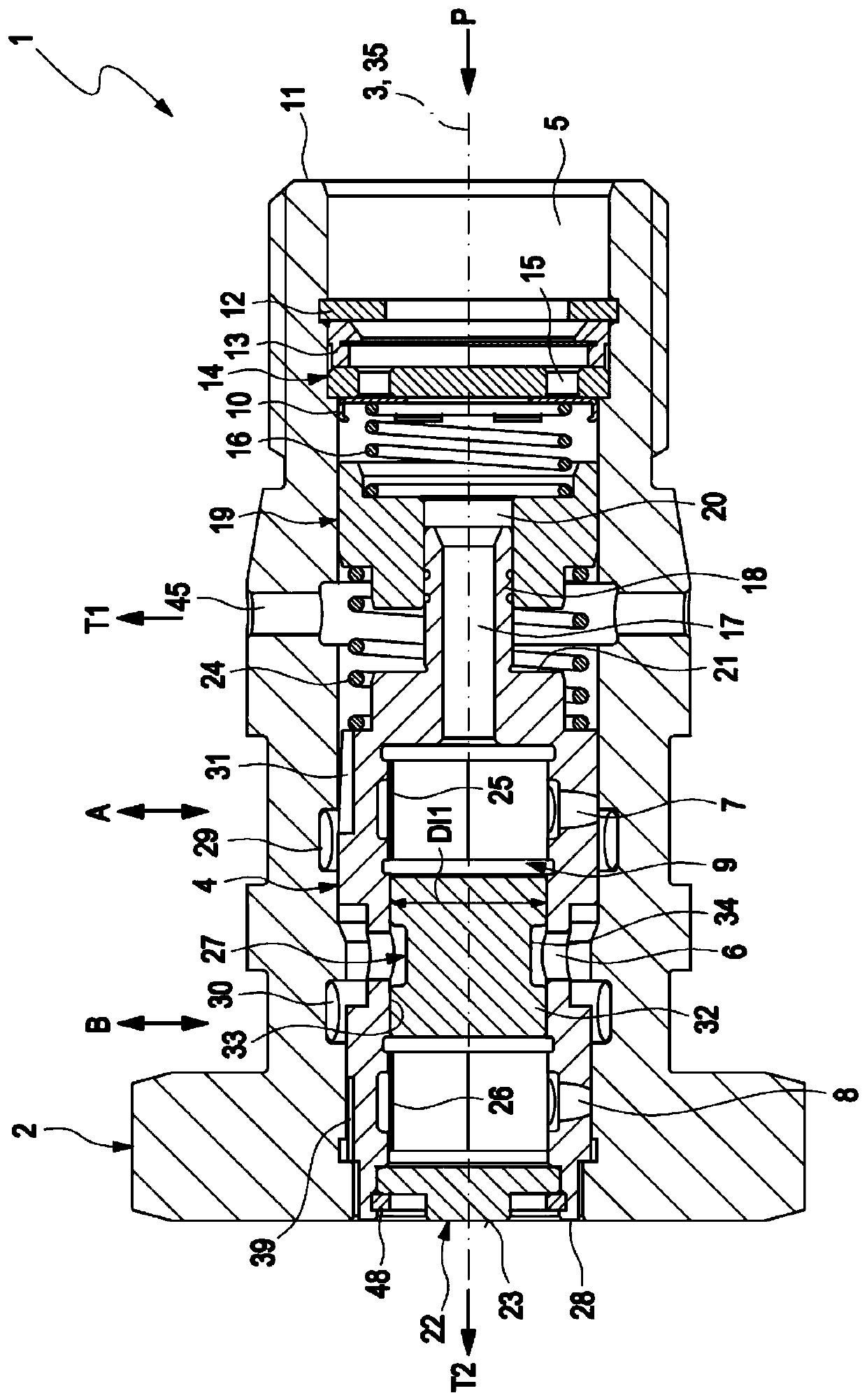

[0043] The hydraulic valve 1 according to the invention for a camshaft phase adjuster not shown in more detail for a camshaft not shown in more detail is designed in accordance with figure 1 in the first embodiment. The hydraulic valve 1 is designed to be accommodated as a central valve in a rotor of a camshaft phase adjuster, not shown in greater detail. In other words, hydraulic valve 1 is accommodated in the central opening of the camshaft phaser so that it is at least partially surrounded by said camshaft phaser.

[0044] The hydraulic valve 1 has a housing 2 designed to allow flow. A plurality of connections A, B, P, T1 , T2 are provided on the housing 2 for the hydraulic supply of the camshaft phaser. In the housing 2 , a piston 4 movable axially along the first longitudinal axis 3 of the hydraulic valve 1 is accommodated in a central opening 5 of the housing 2 . The housing 2 is in most cases of tubular design.

[0045] The camshaft phase adjuster allows, during ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com