Gear mechanism capable of automatically adjusting gap

A gear mechanism, automatic adjustment technology, applied in belt/chain/gear, mechanical equipment, components with teeth, etc., can solve problems such as increase, loud noise, reduce transmission accuracy, etc., achieve tight meshing, reduce noise , Improve the effect of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

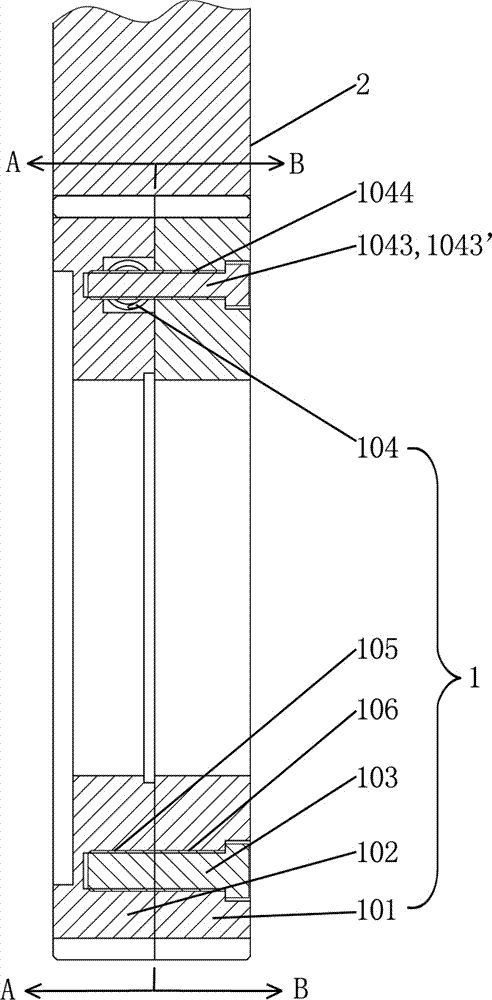

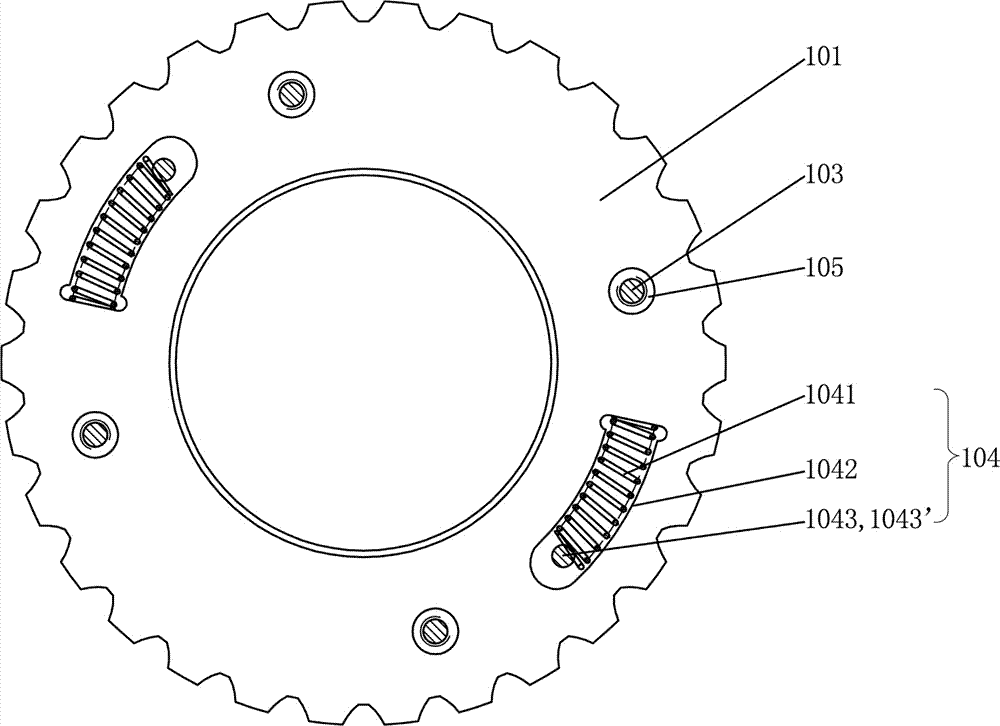

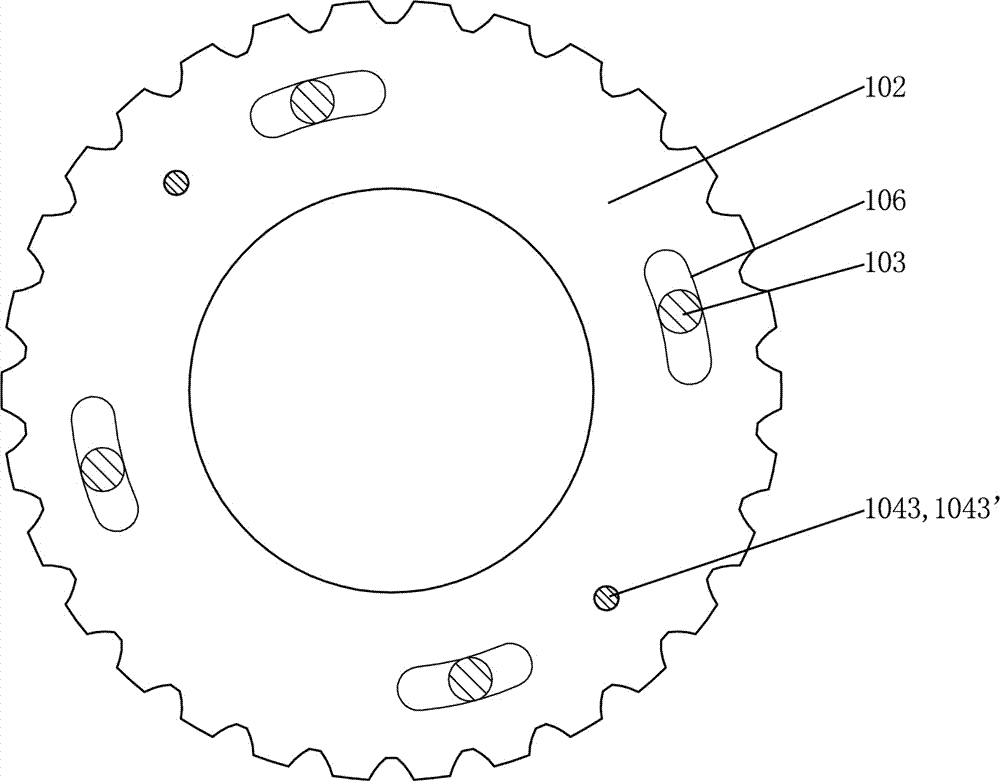

[0015] like figure 1 , figure 2 , image 3 As shown, this gear mechanism that can automatically adjust the gap includes a first gear 1 and a second gear 2 that are meshed; the first gear 1 includes a left minute gear 101, a right minute gear 102, a plurality of locking screws 103 and two An elastic mechanism 104; the left minute gear 101 is provided with a plurality of locking screw holes 105, and the right minute gear 102 is provided with a plurality of arc-shaped through holes 106, and the arc-shaped through holes 106 correspond to the locking screw holes 105 one by one. The left sub-gear 101 and the right sub-gear 102 are locked together by a plurality of locking screw rods 103, wherein the locking screw rods 103 pass through the corresponding arc-shaped through holes 106 and are in the corresponding locking screw holes 105; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com