Gap eliminating type magnetizing clamp

A magnetic fixture and gap-type technology, which is applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems affecting the linearity of sensor output signals, achieve the effects of improving sensor performance, ensuring sensor consistency, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

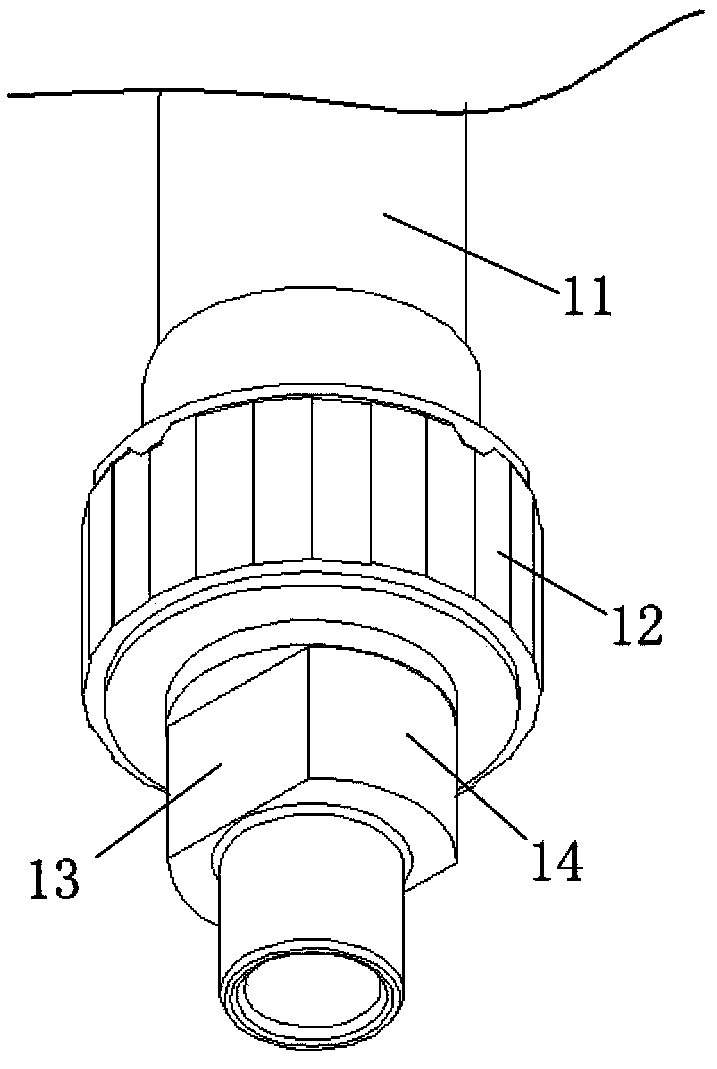

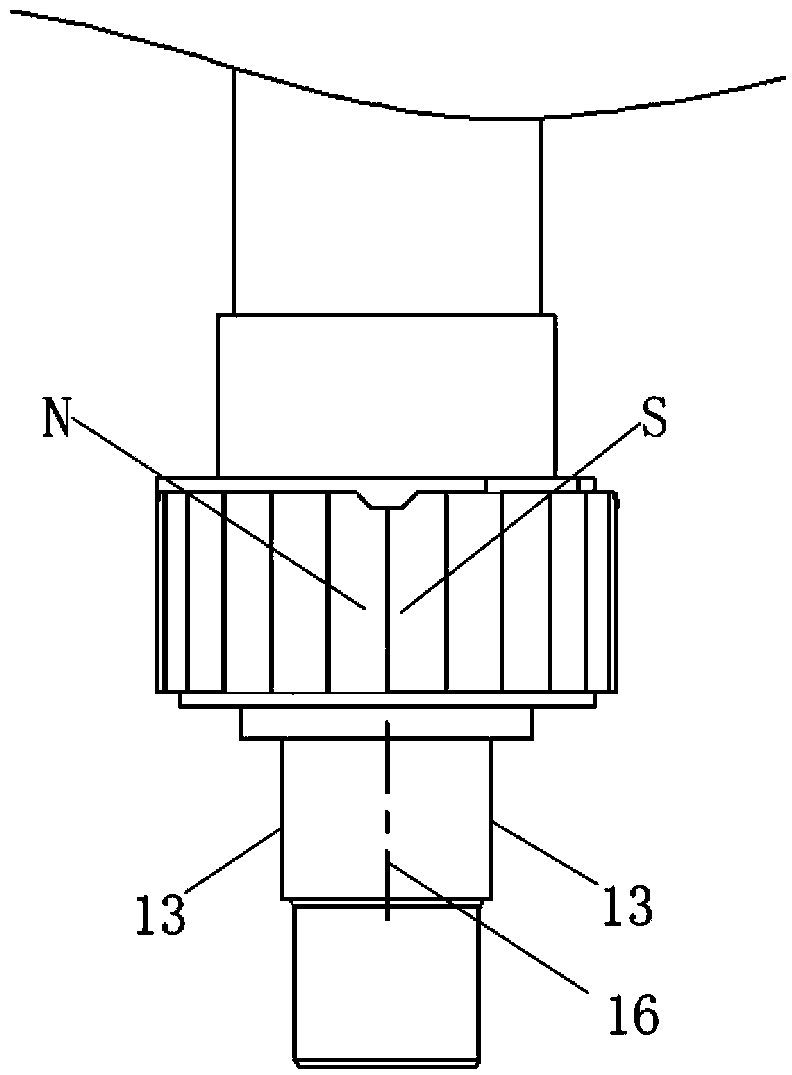

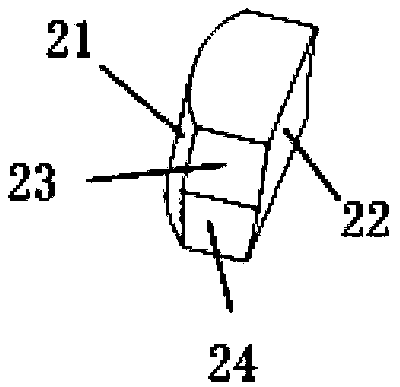

[0030] refer to Figure 3-13 : Gap-eliminating magnetizing fixture, comprising a slider 2, a support 3, and an extruded part 4, the support 3 has a cavity 31 for the input shaft 11 to extend into, and the upper end of the support 3 has a The slot 32 matched with the slider 2, the slot 32 includes a square slot 321 at the upper end and a dovetail slot 322 at the lower end of the square slot 321, the angle between the side and the bottom of the dovetail slot 322 is α, and the slot 32 matching slider 2, its side includes the upper vertical surface 23 and the lower inclined surface 24, the angle between the inclined surface 24 and the horizontal plane is α; the outer edge surface 21 of the slider 2 is from bottom to top and inward Inclined, the inclination angle of the outer edge surface 21 is θ, the extruded part 4 is supported on the upper end of the outer edge surface 21 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com