Rubber-tyred road roller and oil injection system thereof

A fuel injection system and tire-type technology, which is applied in the field of construction machinery, can solve problems such as high cost, difficult control, and rapid cooling of asphalt, and achieve the effects of reducing product manufacturing costs, improving construction quality, and reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

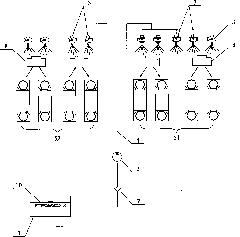

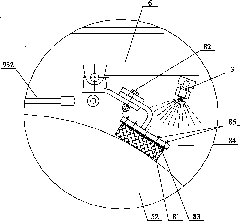

[0030] The core of the present invention is to provide an oil injection system for tire rollers. The system establishes the working pressure of the oil medium in the system pipeline by starting the pump device, and the formed oil medium is output to each spray head. In this way, under the action of pressure, the oil medium sprays oil evenly on the tire tread in the form of mist through the nozzle; as the road roller advances, there is always an oil medium between the tire tread and the road surface, which can ensure that the tire tread On the basis of anti-adhesion performance, the manufacturing cost can be effectively controlled. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

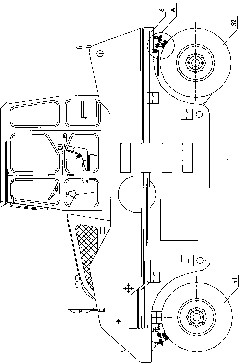

[0031] Without loss of generality, this embodiment uses figure 1 The tire-type road roller shown is taken as an example to describe this embodiment in detail, and the figure shows a schematic diagram of the overall structure of the tire-type roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com