Accessory attaching device

A technology for laminating equipment and accessories, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of inability to meet industrial needs, high labor intensity of operators, etc., to improve efficiency, reduce labor intensity, and reduce transfer. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

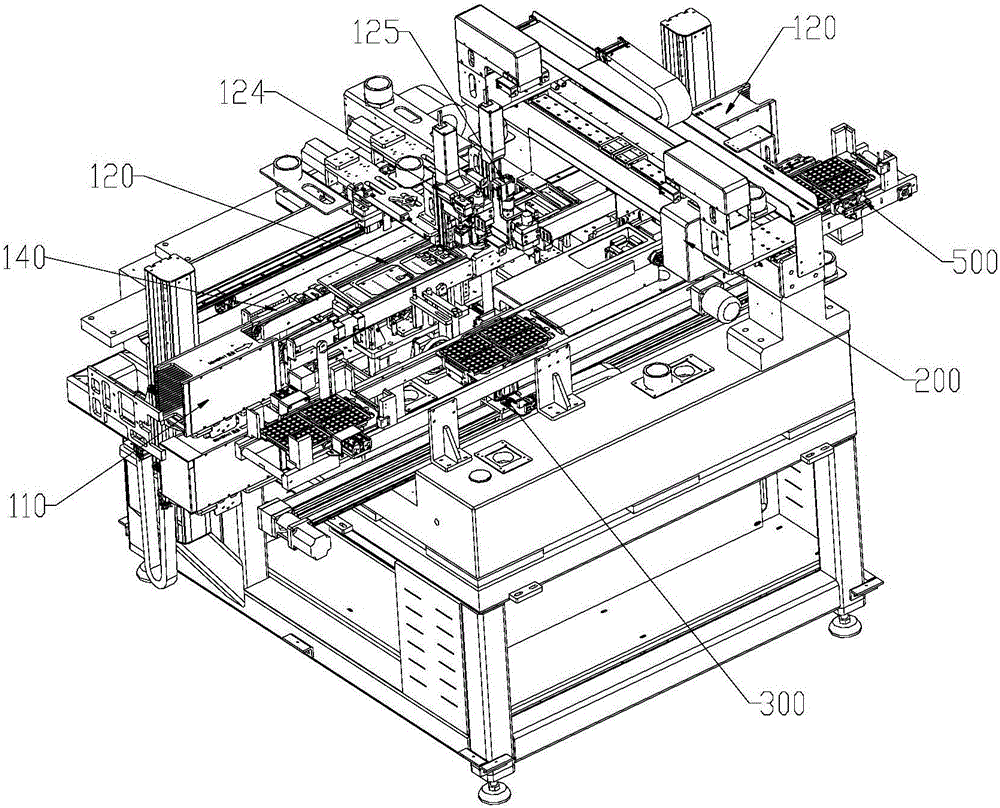

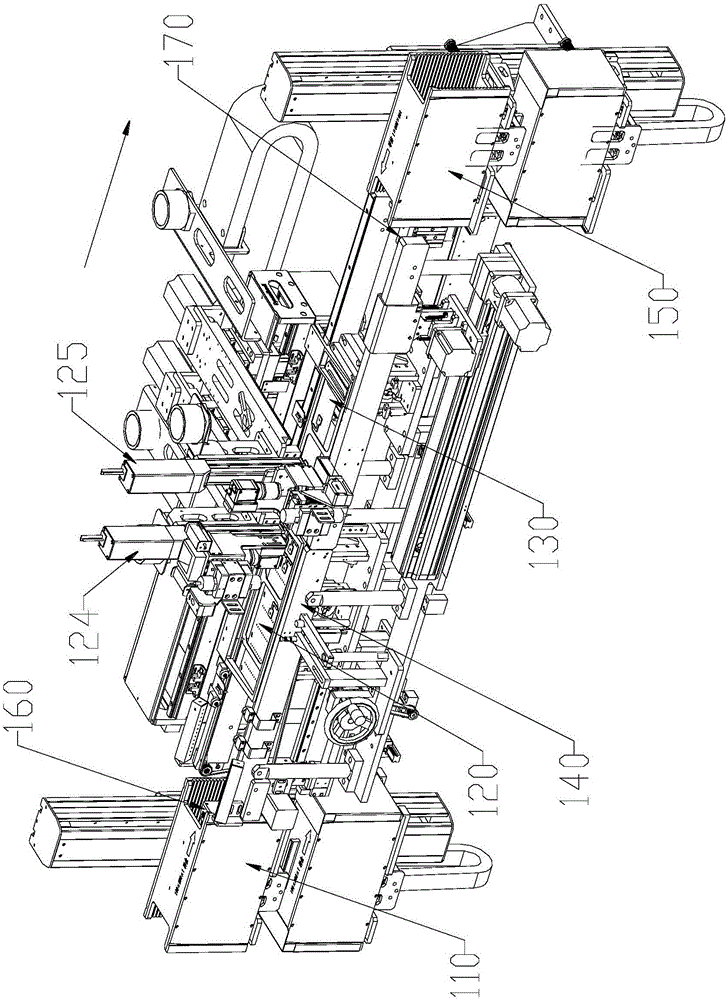

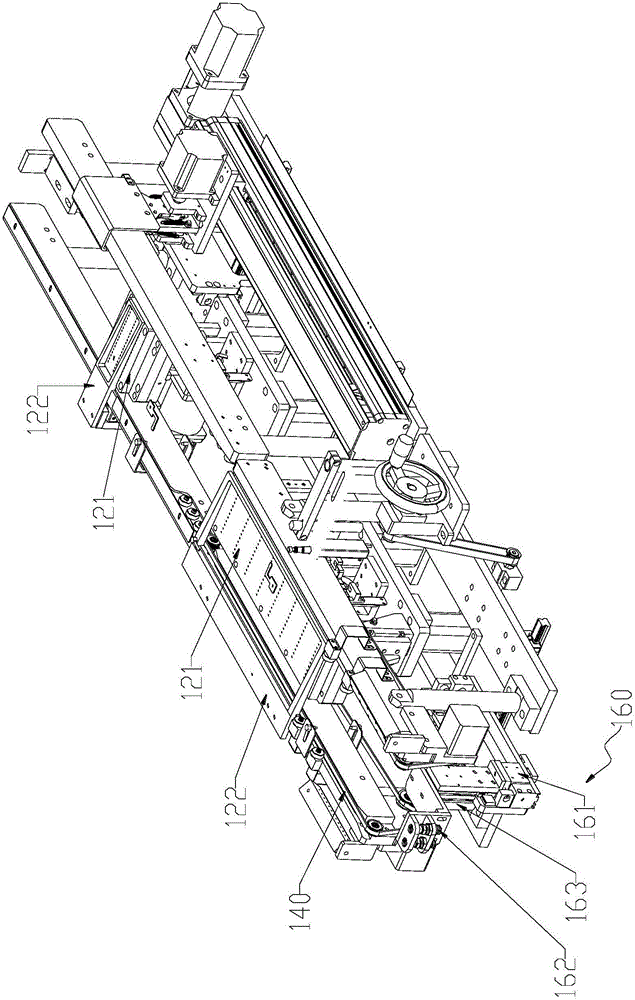

[0034] Such as Figure 1-9 As shown, accessories fit the device, including,

[0035] Circuit board dispensing station 120;

[0036] Fitting station 130;

[0037] Parts supply station for supplying parts;

[0038] A circuit board carrier for carrying circuit boards;

[0039] The circuit board conveying device 140 is used to convey the circuit board carrier and drive the circuit board carrier to pass through the circuit board dispensing station 120 and the bonding station 130 in sequence;

[0040] And the manipulator 200 is used to transfer the accessories from the accessory supply station to the circuit board at the bonding station 130 .

[0041] During the working process, the circuit board carrier tray loaded with circuit boards is first transported to the circuit board dispensing station 120 for dispensing via the circuit board conveying device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com