Film pasting method for 3D glass, tool used for 3D glass film pasting and film pasting device

A technology of glass film sticking and film sticking device, which is applied in the field of 3D glass film sticking tools and film sticking equipment. The effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

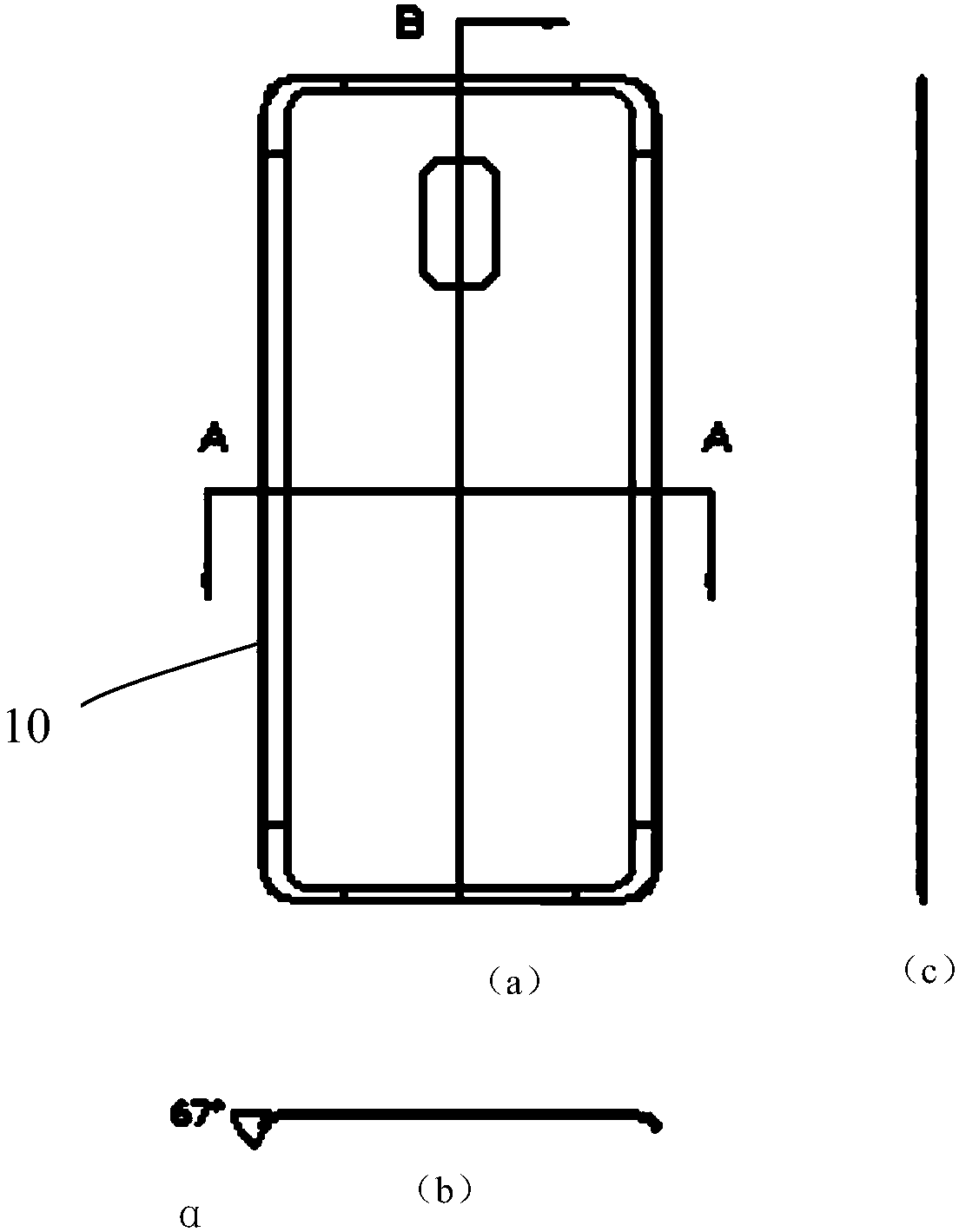

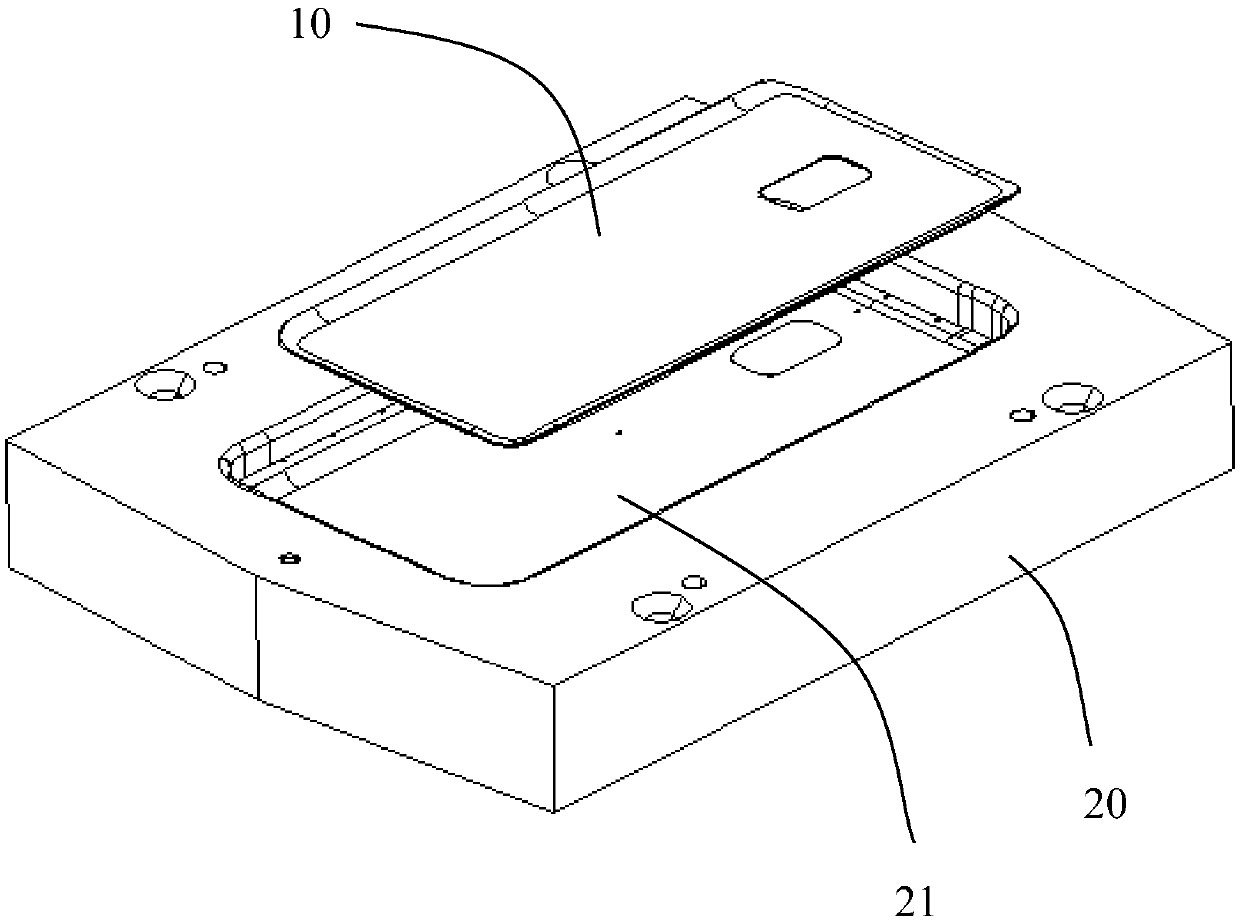

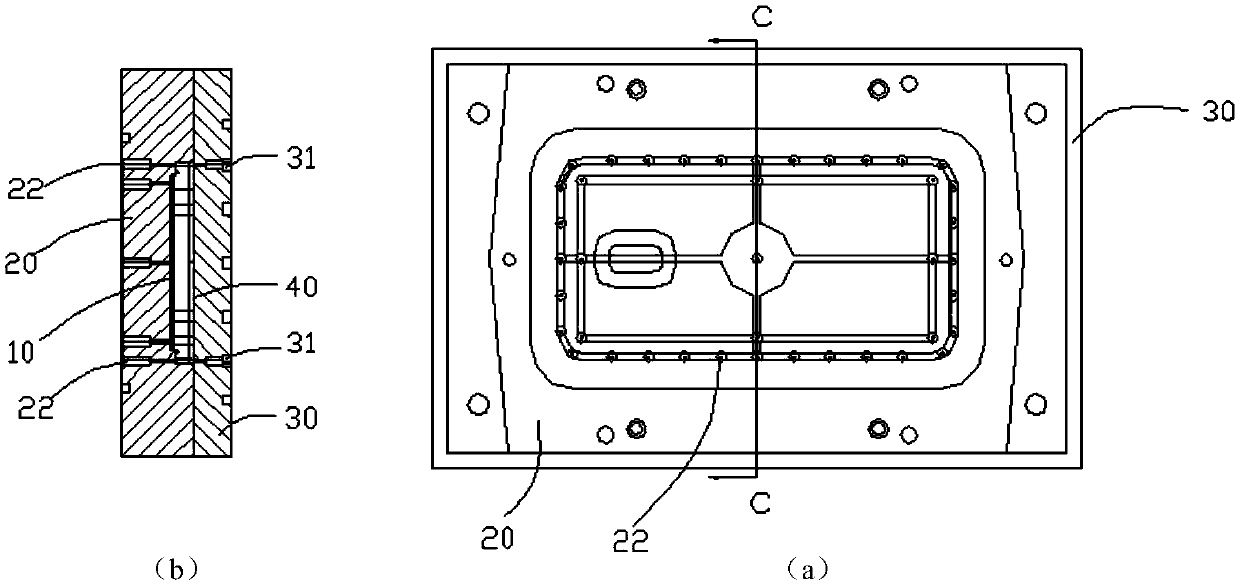

[0064] Such as Figure 2-Figure 4 As shown, this embodiment is a tooling tool for 3D glass film sticking, including a base plate 20 and a film absorbing plate 30 that is sealed with the base plate 20 and is used to absorb the decorative film 40 . The groove 21, the bottom plate 20 and the film suction plate 30 are all provided with ventilation holes.

[0065] The tooling tool for 3D glass film sticking provided by the present invention includes a base plate 20 and a film absorbing plate 30 for absorbing a decorative film 40. The base plate 20 is provided with a groove 21 for placing the 3D glass 10. The base plate 20 and the film absorbing plate 30 can be covered. After closing and covering, a closed space for accommodating the 3D glass 10 and the decorative film 40 will be formed in the middle. On the bottom plate 20 and the suction film plate 30, air holes are all arranged, and the evacuation process to the closed space can be realized through the air holes on the bottom pl...

Embodiment 2

[0072] This embodiment provides a method for attaching a film to 3D glass. The bonding equipment used in the method for attaching the film includes the tooling tool for attaching a film to 3D glass in Example 1, which specifically includes the following steps:

[0073] Step a) Loading: Lay the 3D glass flat in the groove of the bottom plate, and use the film-absorbing plate to absorb the decorative film; when absorbing the decorative film, use the CCD alignment method to grab the decorative film, and according to the decorative film and the film-absorbing plate Positioning holes on the suction plate to place it at a specific position;

[0074] Among them, the heat-resistant temperature of the decorative film is 120°C;

[0075] Step b) heating: using infrared heating to heat the decorative film to 110°C to soften the decorative film;

[0076] Step c) Vacuuming: After the film-absorbing plate is combined with the base plate, the 3D glass and the decorative film are located in t...

Embodiment 3

[0081] This embodiment provides a method for attaching a film to 3D glass. The bonding equipment used in the method for attaching the film includes the tooling tool for attaching a film to 3D glass in Example 1, which specifically includes the following steps:

[0082] Step a) Loading: Lay the 3D glass flat in the groove of the bottom plate, use the film absorbing plate to absorb the decorative film; when absorbing the decorative film, use the CCD alignment method to grab the decorative film, and according to the positioning hole on the decorative film Place it on the specific position of the suction film plate;

[0083] Among them, the heat-resistant temperature of the decorative film is 130°C;

[0084] Step b) heating: using infrared heating to heat the decorative film to 115°C to soften the decorative film;

[0085] Step c) Vacuuming: Then position according to the positioning holes on the decorative film, the bottom plate and the suction film plate, cover the suction film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com