System for filtering fluids

A technology for filtering fluids and fluids, applied in the direction of filtration and separation, membrane filters, fixed filter elements, etc., can solve the problems of difficult filtration process and high viscosity backwashing process, and achieve the effect of preventing idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

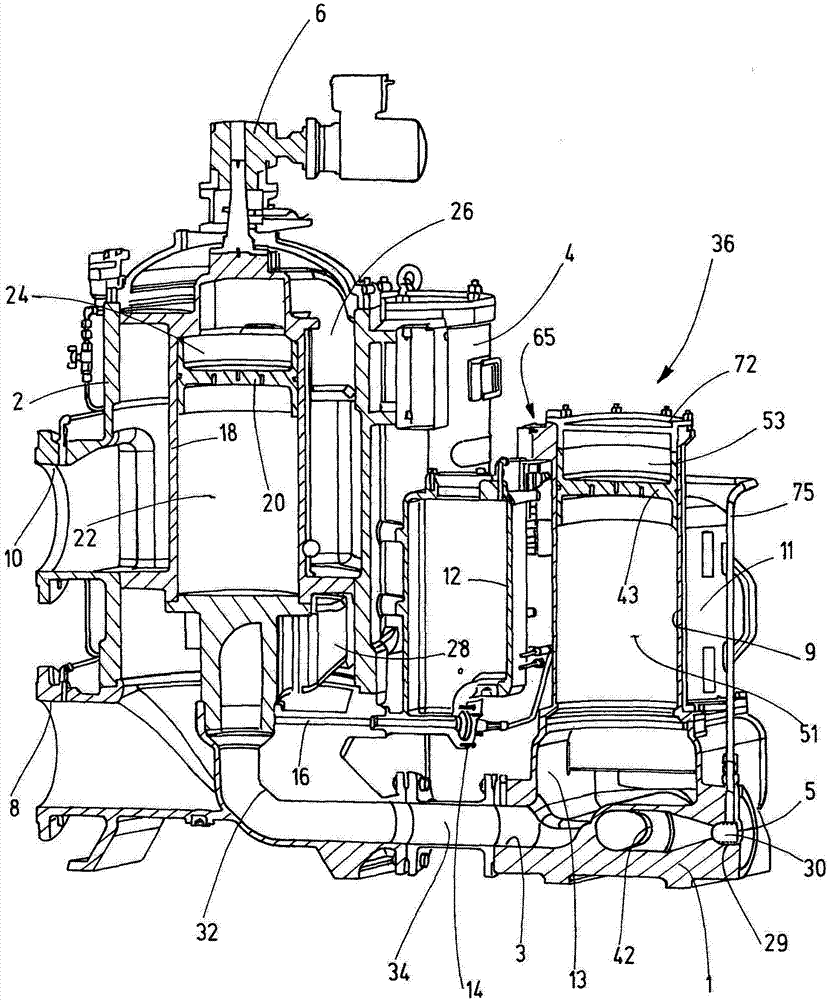

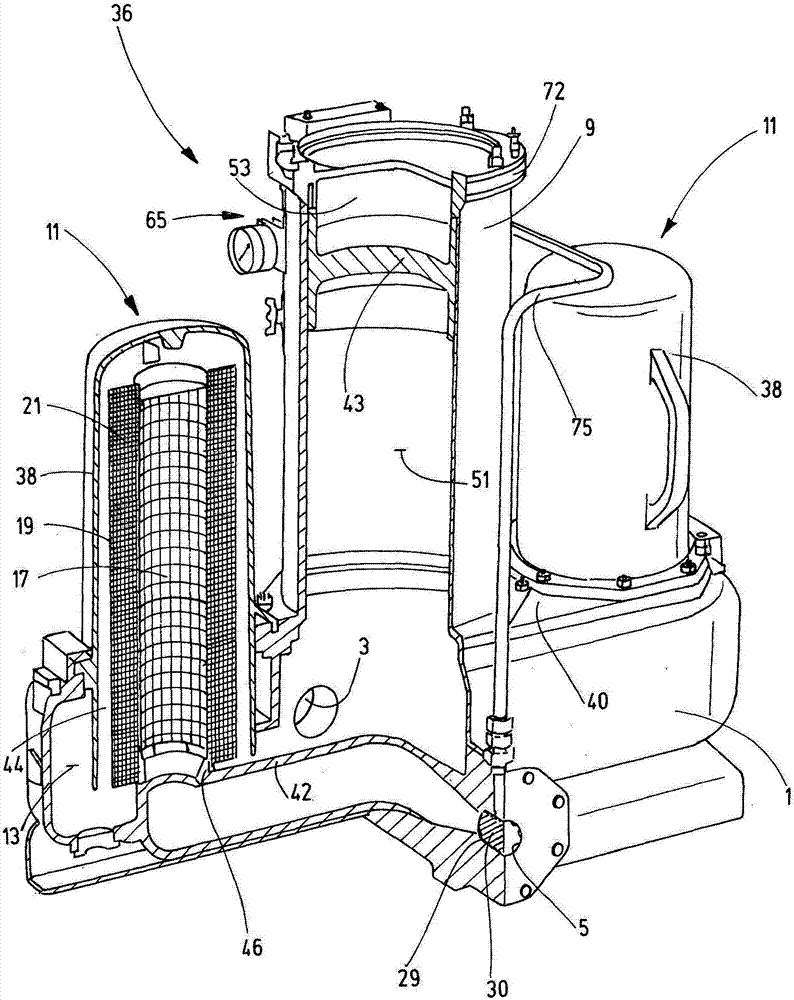

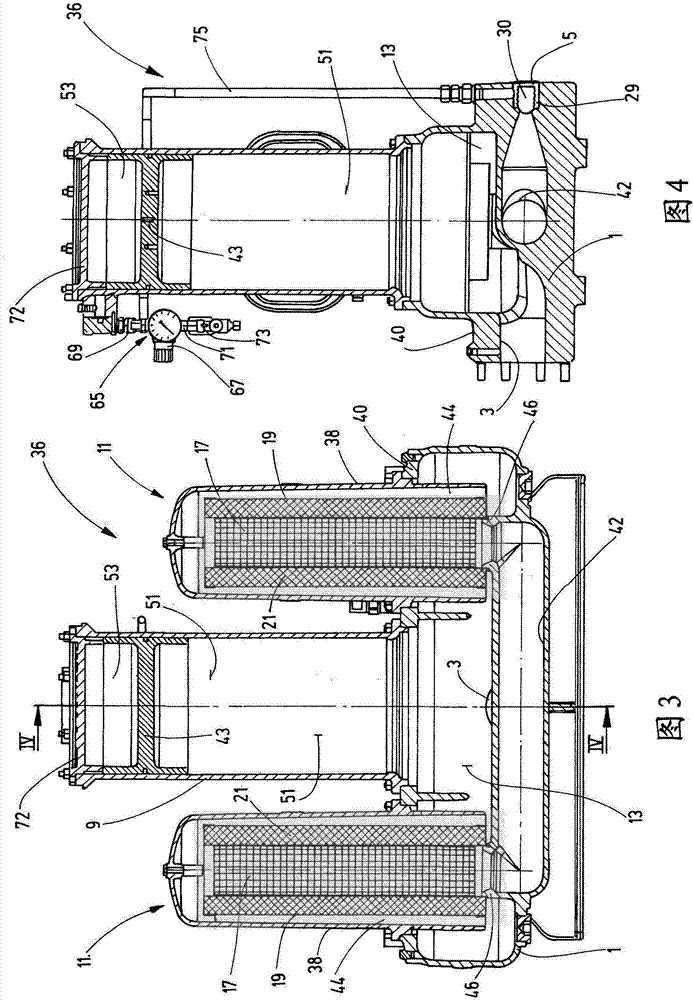

[0027] exist Figure 1 to Figure 4 In a first embodiment of the system according to the invention shown in , the primary filter (its main housing is in figure 1 Marked with 2 in ) corresponds to the backflush filter device described in the above-mentioned document WO 2012 / 150011 A1 and incorporated by reference. Thus, in figure 1 Not all details of the known device are shown in the simplified view of , but only the details of the backwash filter device which are important for understanding the system according to the invention are shown, as primary filter according to components of the system of the present invention. However, it is readily understood that different types of backflush filter devices can be provided as primary filters, for example the backflush filter device disclosed in the already mentioned document DE 10 2011 100 518 A1.

[0028] An inlet 8 for the non-filtrate to be cleaned and an outlet 10 for the cleaned fluid are provided on the main housing 2 and on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com