A Calculation Method for Back-to-Back Tapered Roller Bearing Arrangement

A technology of tapered roller bearing and calculation method, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of measurement difficulty, bearing load and life impact, cumbersome and other problems, so as to solve mass production problems, improve inaccuracy problems, solve problems Effects of preload problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

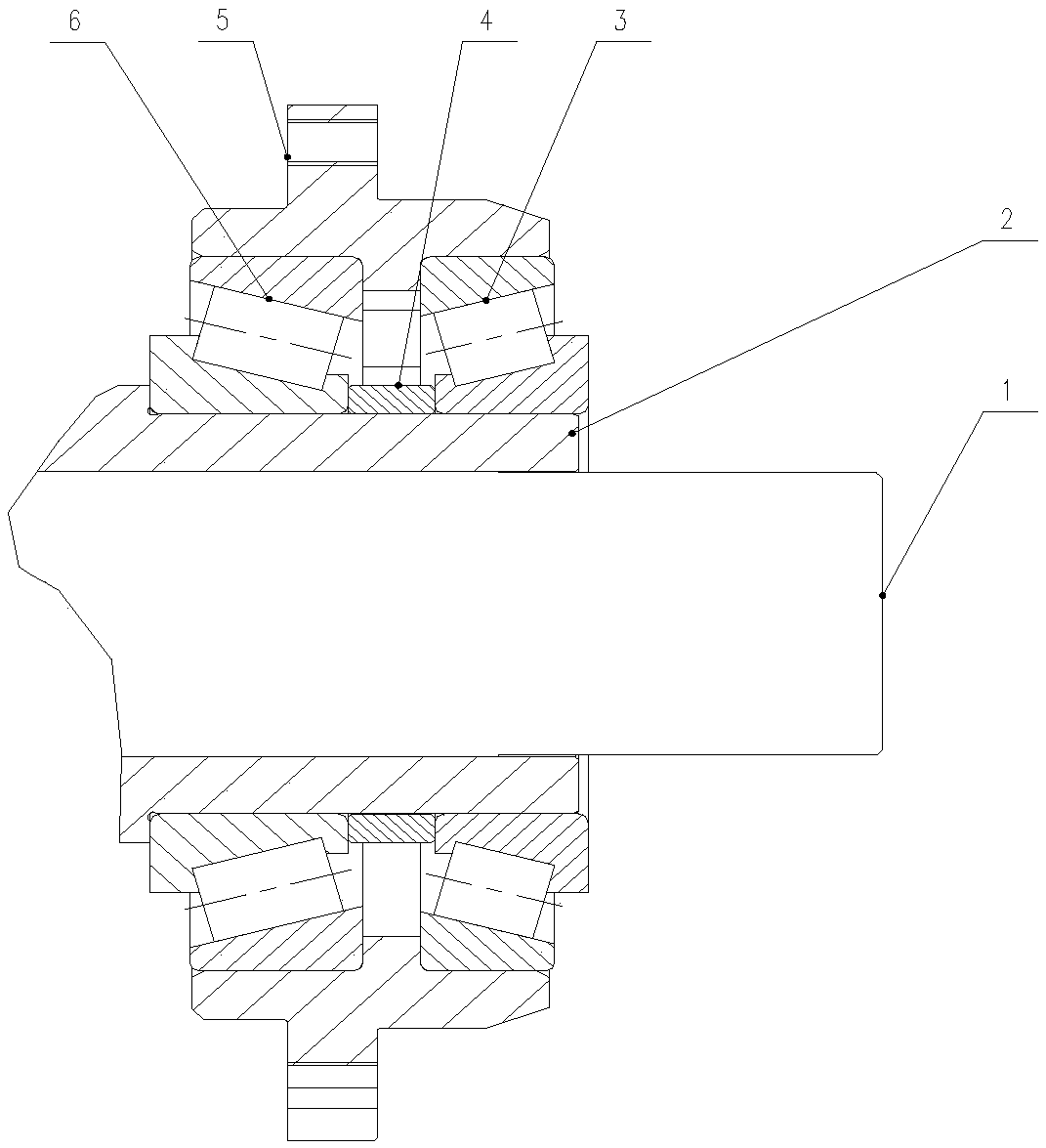

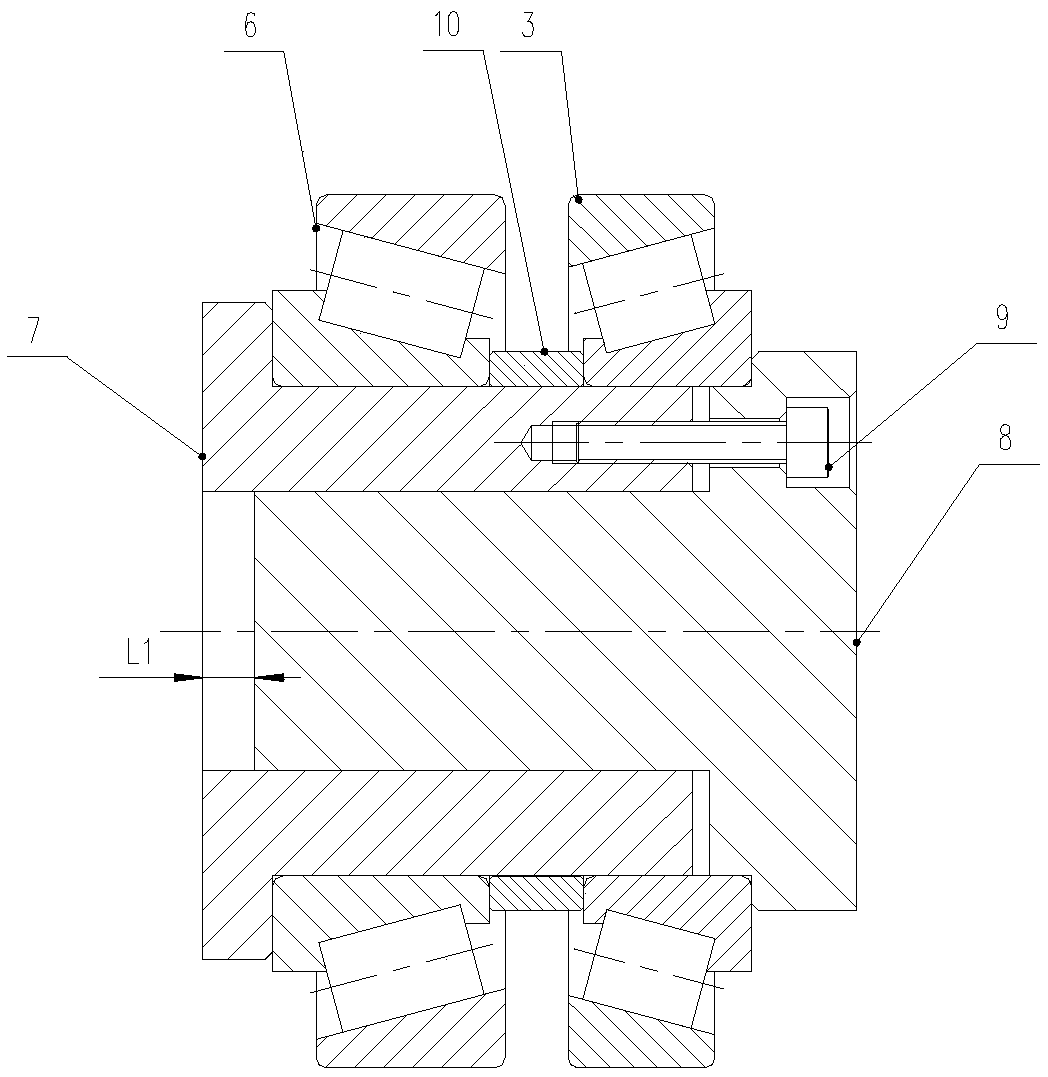

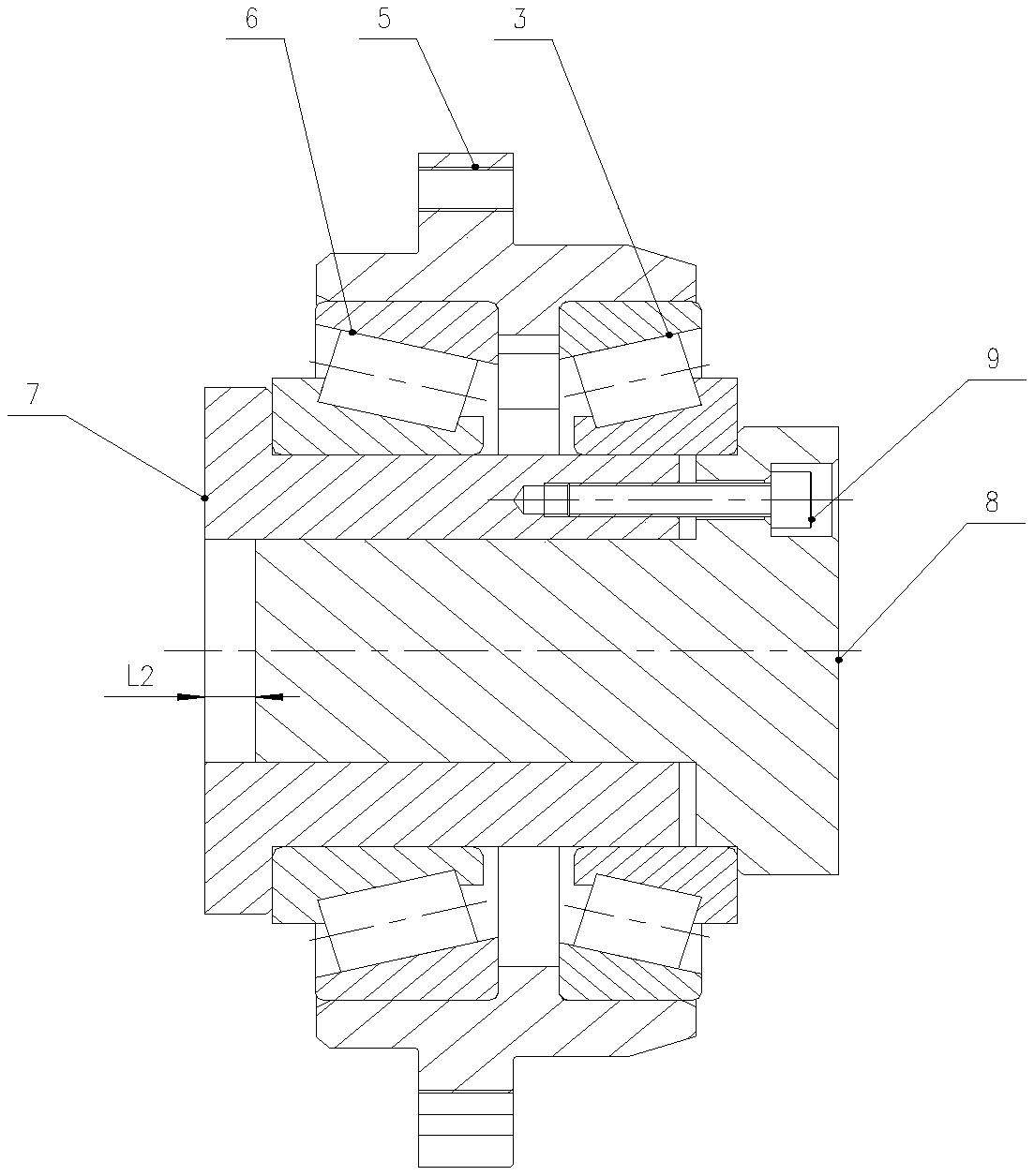

[0037] The method for calculating the arrangement of back-to-back tapered roller bearings in the present invention includes a set of measuring tooling and a reference inner spacer ring. Because the back-to-back tapered roller bearings are provided with various types of outer spacers and inner spacers, the present invention only describes one structural form, and the others are similar. The invention also relates to an outer bearing housing, a bushing and a shaft. Assemble the inner ring of the tapered roller on the measuring tool, in order to pre-tighten the bearing, the tightening torque of the screw is 1Nm, and the difference of the size of the inner ring on the measuring tool is L1, assemble the outer ring of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com