Concrete stirring and transporting all-in-one vehicle

A mixing and transporting integrated technology, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of low safety, high labor intensity, affecting production efficiency and benefits, and achieve the goal of avoiding U-turn operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

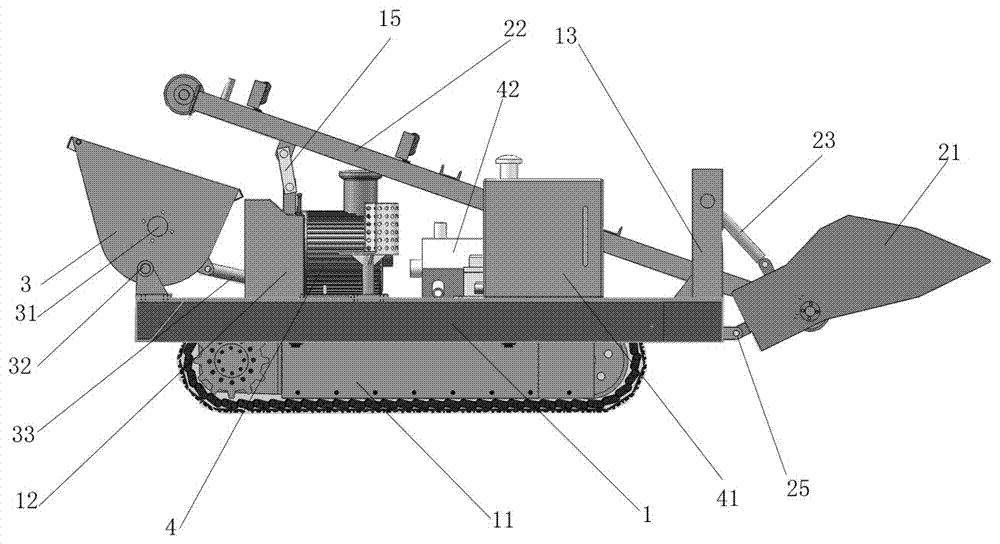

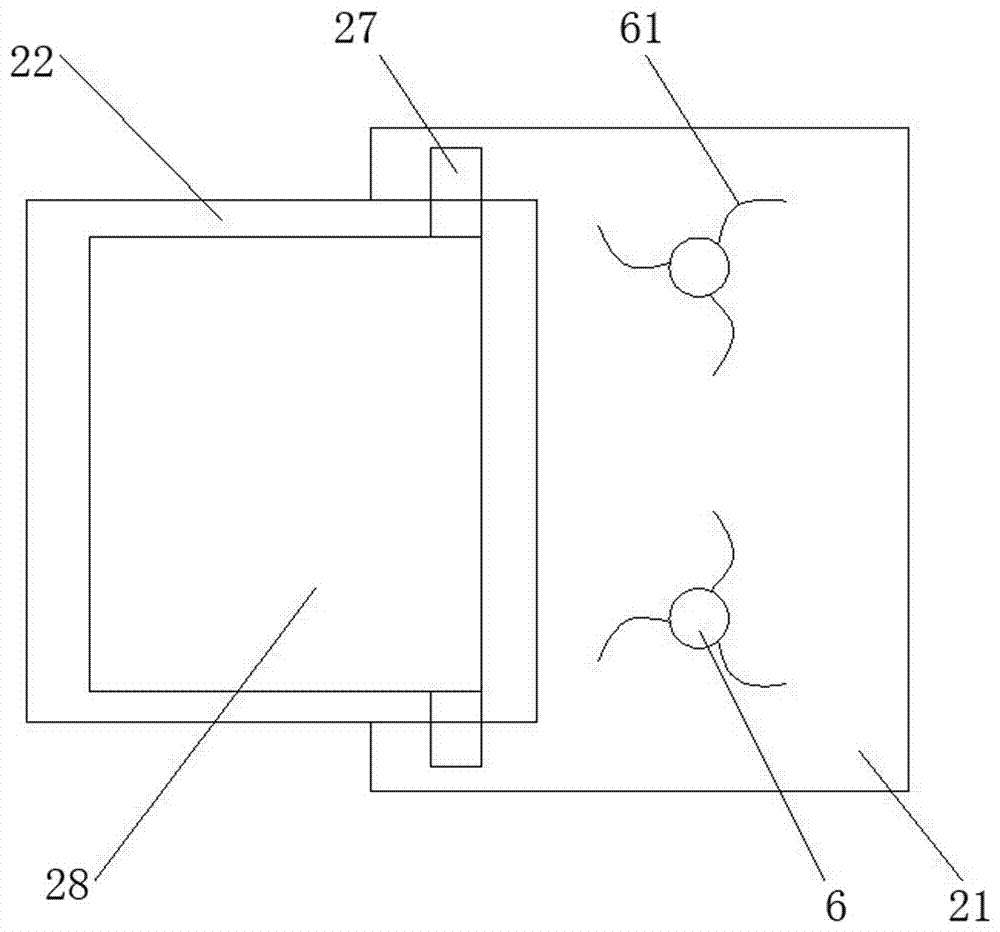

[0013] as attached figure 1 , figure 2 As shown, a concrete mixing and transporting integrated vehicle includes a bearing platform 1, a fixed crawler running device 11 under the bearing platform, a fixed oil cylinder support frame 13 at the front end above the bearing platform, and a hinged bucket 21 at the front end (see reference numerals for the hinge points 25), the bucket 21 is hinged to one end of the bucket cylinder 23, and the other end of the bucket cylinder 23 is hinged to the cylinder support frame 13.

[0014] The rear end above the bearing platform 1 is hinged to the bottom of the stirring bin 3 opened above (the hinge point is referred to reference numeral 32), and the stirring bin 3 is provided with a stirring device (not shown in the figure), and the stirring bin 3 is hinged to the mixing cylinder 33 One end, the other end of the mixing cylinder is hinged on the carrying platform 1 .

[0015] A transmission belt device is provided between the bucket 21 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com