A detection method for complex multi-pipeline system

A detection method and pipeline system technology, which is applied in the detection field of complex multi-pipeline systems, can solve problems such as the inability to obtain complex multi-pipeline detection, and achieve the effects of rich results, easy operation, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

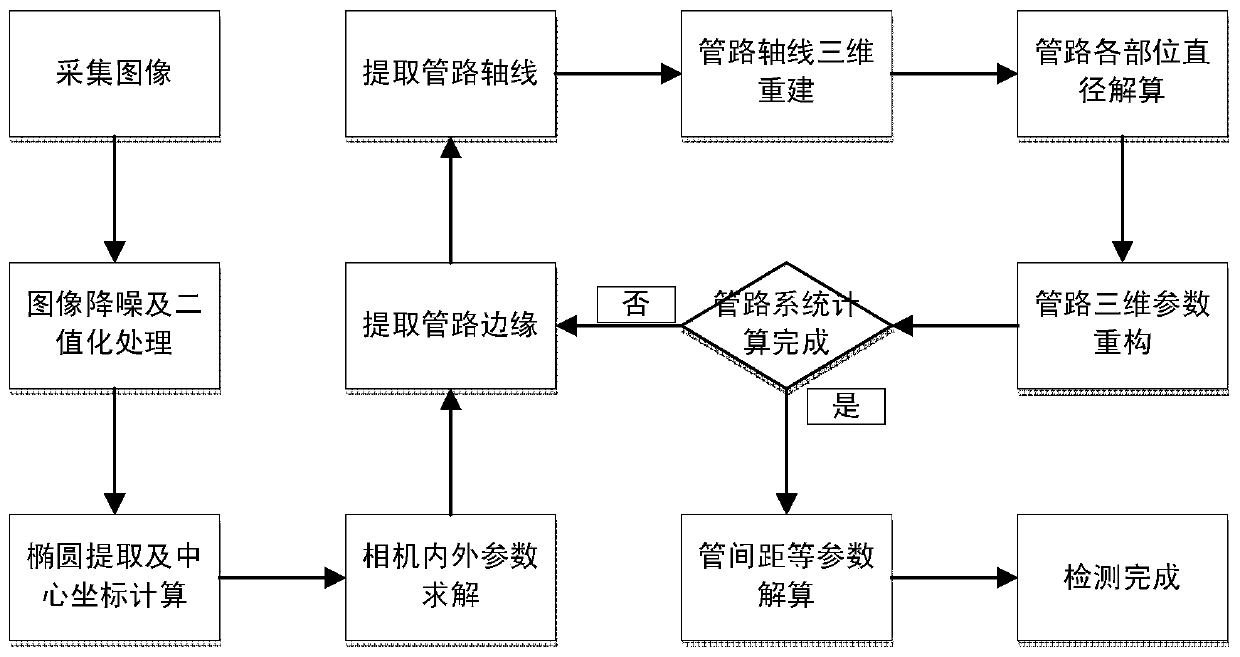

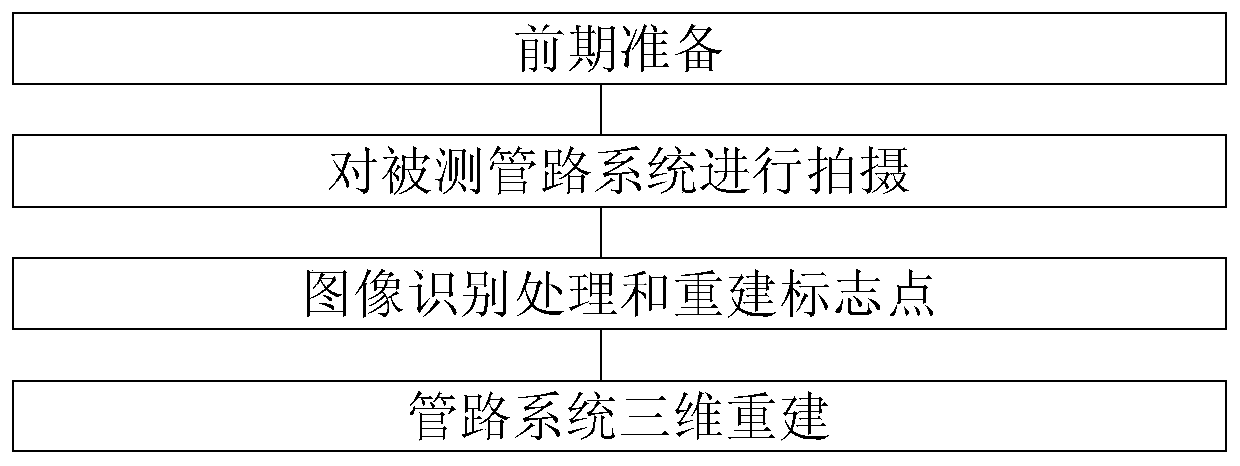

[0041] This embodiment is a detection method for a complex multi-pipeline system, comprising the following steps:

[0042] The first step: preliminary preparation.

[0043] The preparatory preparations include pasting markers and placing rulers.

[0044]On the surface of the accessories in the pipeline system to be tested, according to the principle requirements of photogrammetry, mark points are pasted according to the size of the pipeline system to be tested and the measurement requirements; the accessories are other components in the pipeline system except the pipeline, including Valves, pumps, connections and fixtures. The marker points used include coded marker points and non-coded marker points, and the total number of coded marker points in each image is not less than 5, and the number of common coded marker points contained in two adjacent images is greater than 3; the said The image of is a picture of the surface of the pipeline system to be tested taken by the came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com