Cable feeding apparatus for fireproof cable of device

A fire-resistant cable and equipment technology, applied in the field of equipment fire-resistant cable inlet device, can solve the problems of destroying the original appearance of equipment, equipment factory warranty conflicts, long cycle, etc., to achieve convenient plugging of cables, long solution cycle, and overcome space shortage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

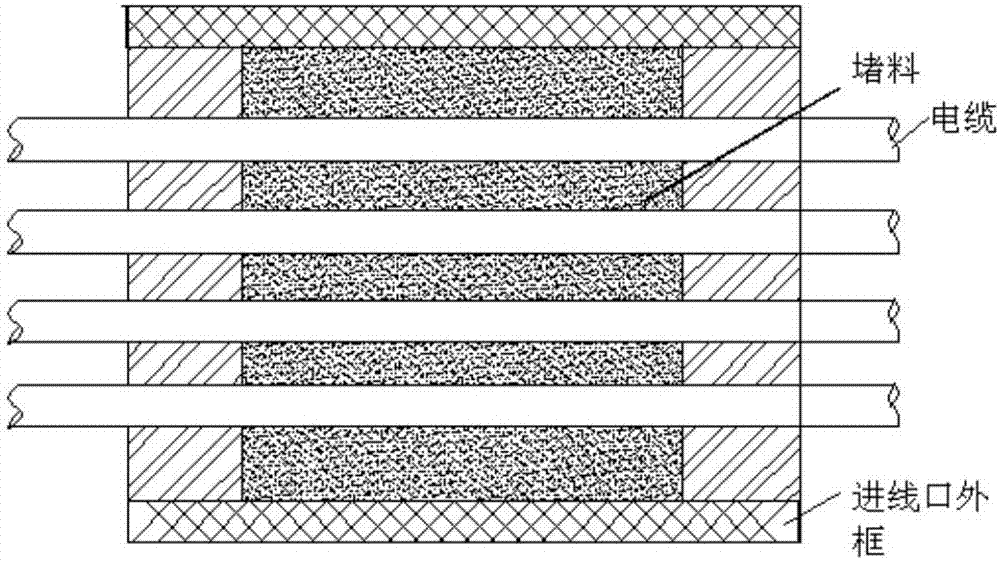

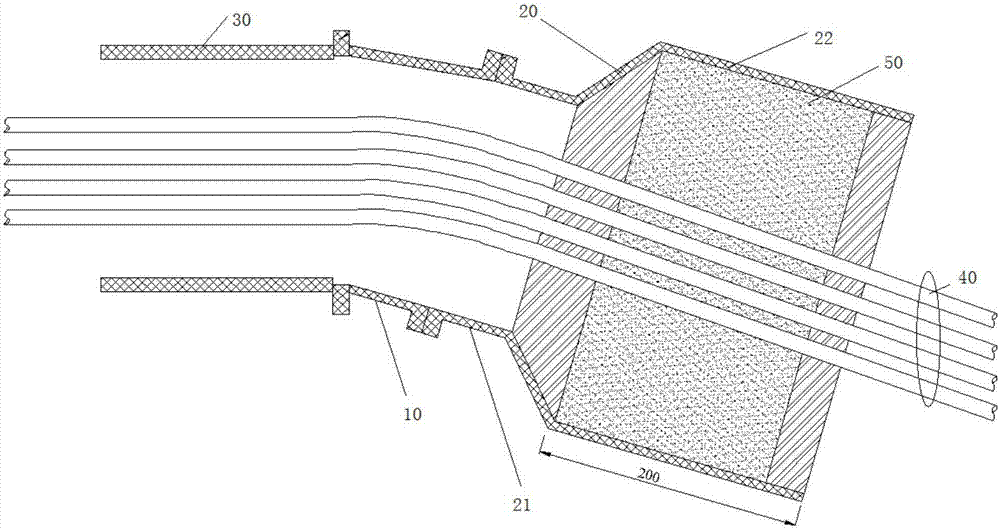

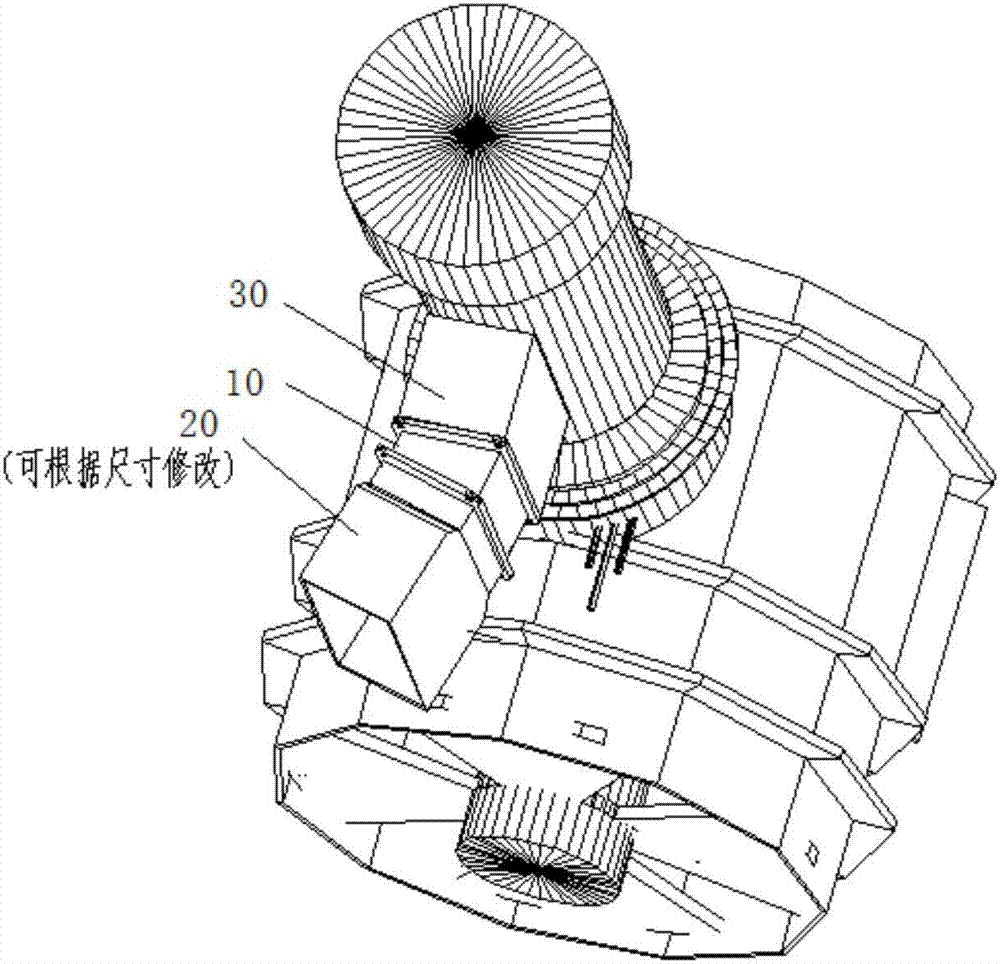

[0021] Please refer to figure 2 , the embodiment of the present application provides an incoming device for equipment fire-resistant cables, which is applied to the connection of ship fire-resistant cables, and the device includes:

[0022] transfer elbow 10;

[0023] The widening joint 20 includes a connecting end 21 and a widening end 22, the connecting end 21 is fixedly connected to one end of the transfer elbow 10, and the inner diameter of the widening end 22 is larger than the inner diameter of the equipment inlet 30;

[0024] When the inner diameter of the equipment inlet 30 is smaller than the preset inner diameter corresponding to the fire-resistant cable bundle 40, the other end of the transfer elbow 10 is used for fixed connection with the equipment inlet 30, and the fire-resistant The cable bundle 40 is inserted into the equipment inlet 30 from the inside of the widening joint 20 and the transition elbow 10, and the inner cavity of the widening end 22 is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com