Automatic dispensing system for new medicine research and development

A technology for automatic dispensing and new drugs, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. and other problems, to achieve the effect of improving the titration efficiency and shortening the research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

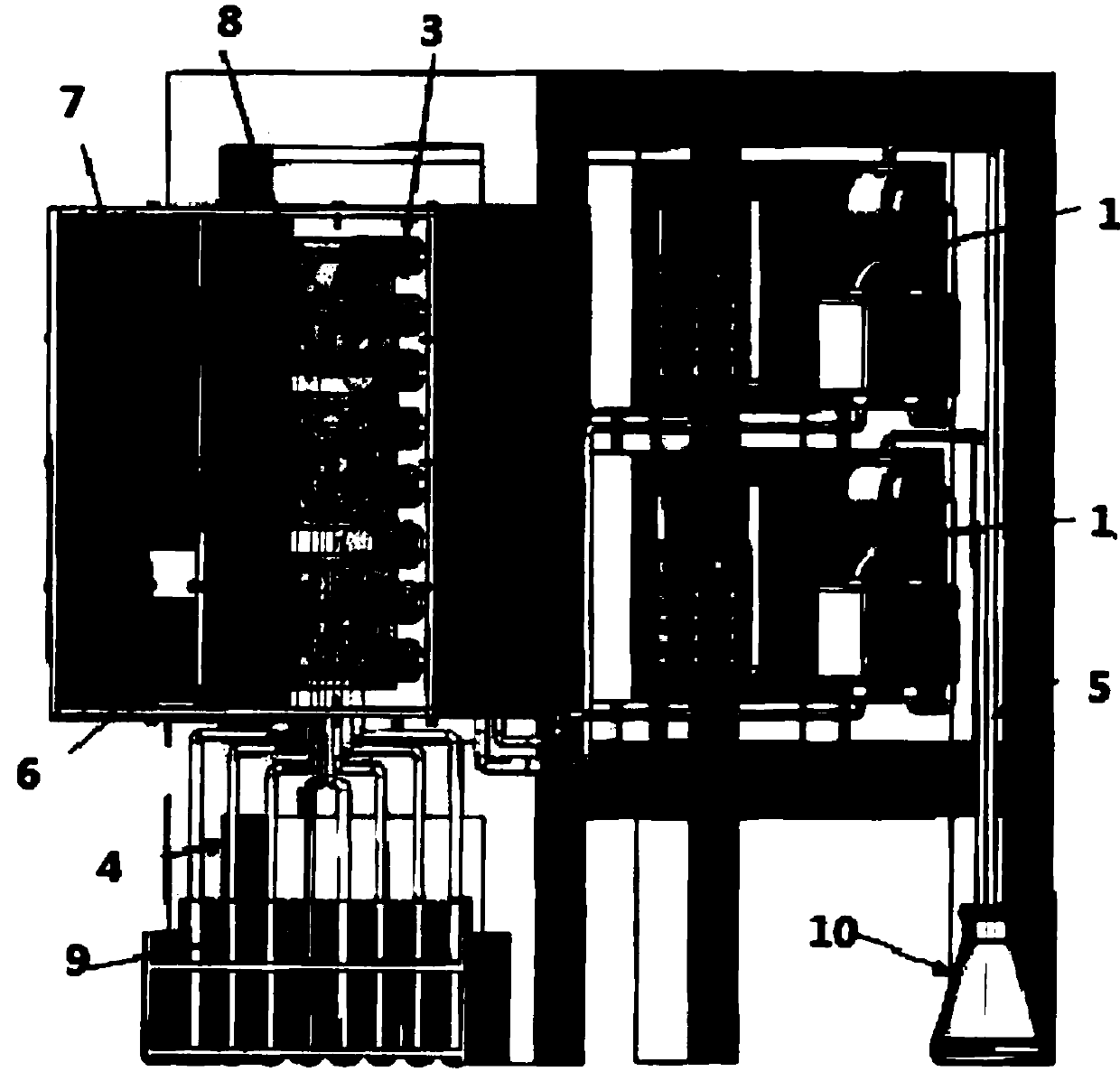

[0034] refer to Figure 1-2 As shown, an embodiment of the automatic dispensing system for new drug research and development of the present invention includes an infusion device 1, a pipeline converter 2, a solenoid valve 3, a liquid inlet pipeline 4, a liquid outlet pipeline 5, a control module 6, and a power supply module 7 ;

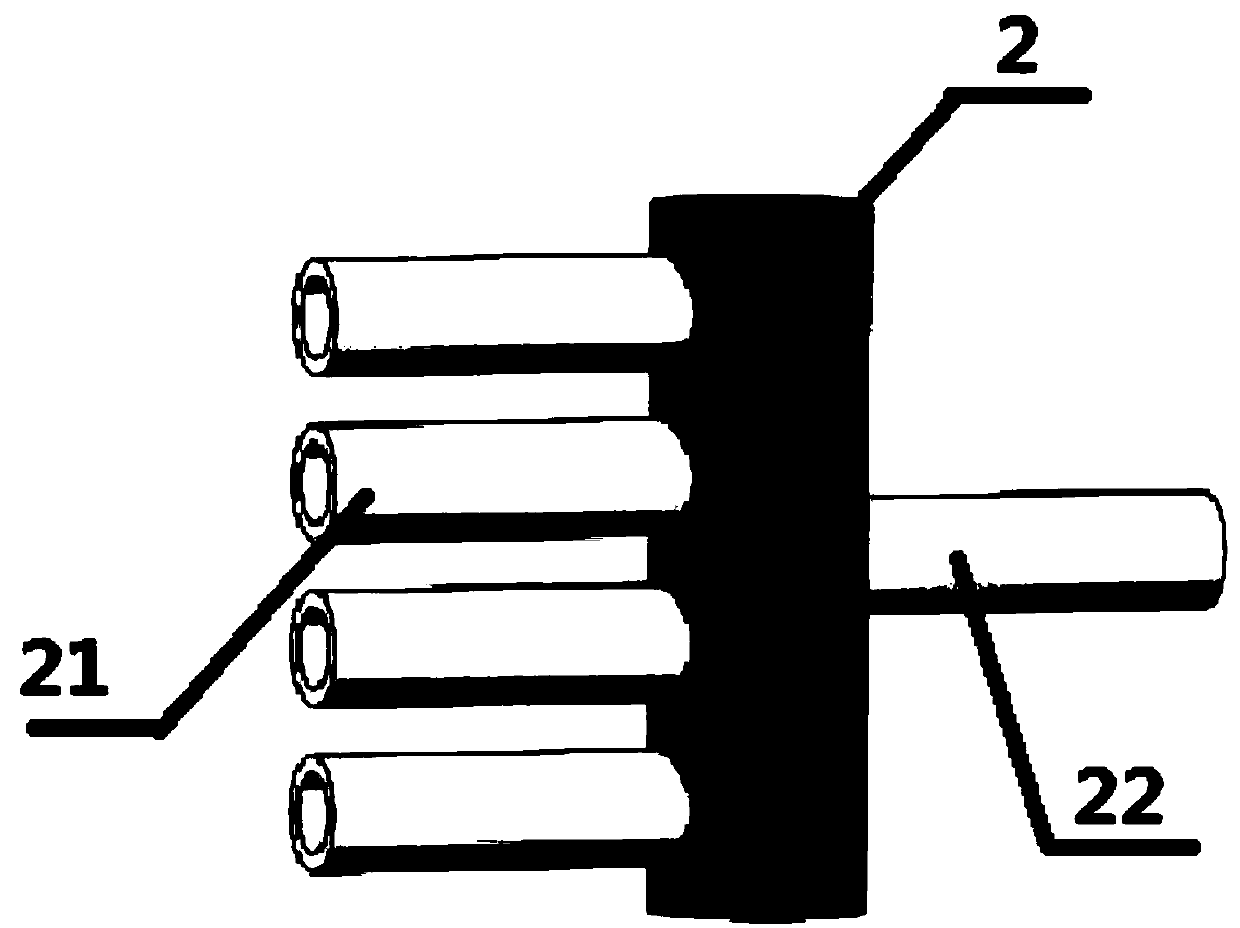

[0035] The pipeline converter 2 is provided with several liquid inlets 21 and a liquid outlet 22, each of the liquid inlets 21 communicates with the liquid inlet pipeline 4, and the liquid outlet 22 communicates with the infusion device 1 connected, the main function of the pipeline converter 2 is to mix the raw material liquids from multiple inlets together;

[0036] One end of the infusion device 1 communicates with the liquid inlet pipe 4 through the pipeline converter 2 for extracting the liquid in the liquid inlet pipe 4, and the other end of the infusion device 1 communicates with the liquid outlet pipe 5;

[0037] The solenoid valve 3 is arra...

Embodiment 2

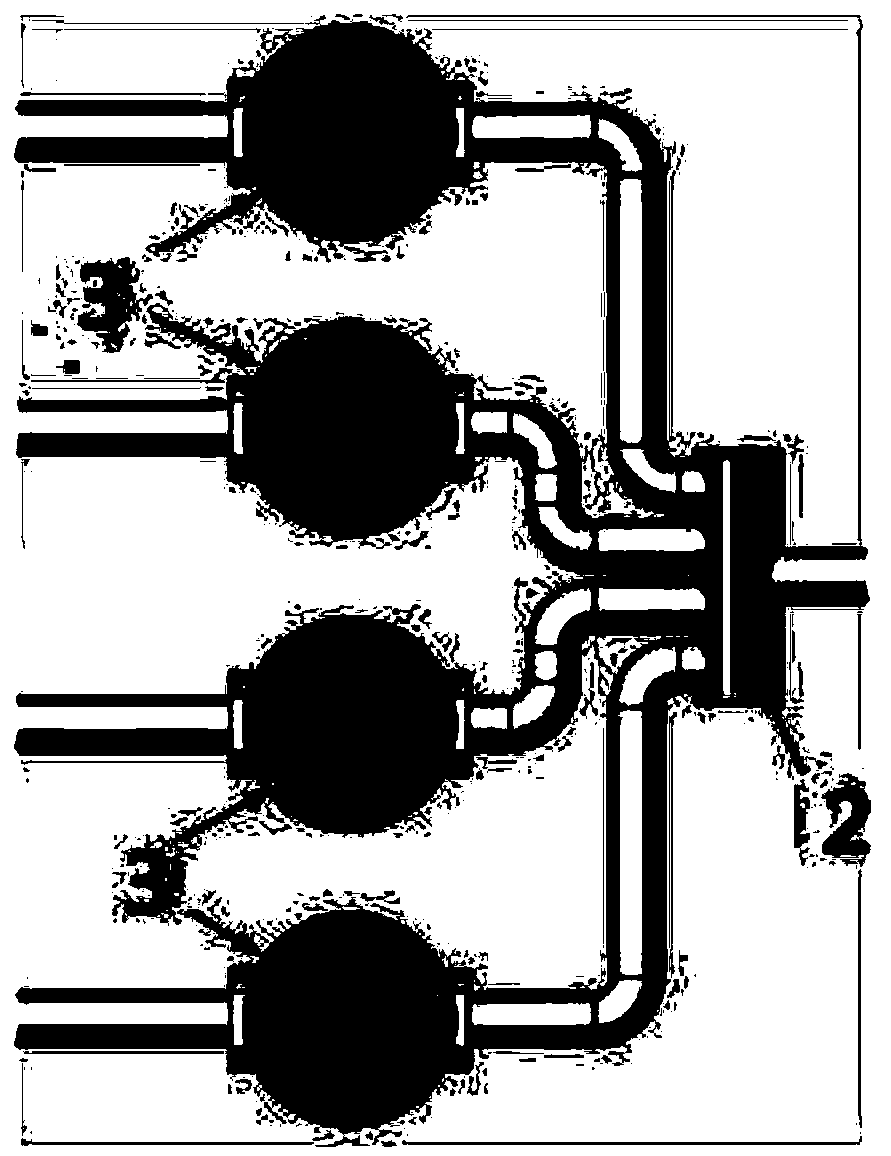

[0043] refer to Figure 4 As shown, it is another embodiment of the present invention. In this embodiment, two pipeline converters 2 and two infusion pumps are provided, and each pipeline converter 2 is provided with four liquid inlets 21 and one outlet. A liquid port 22, a solenoid valve 3 is arranged between each liquid inlet 21 and the liquid inlet pipe 4, and each liquid outlet 22 is connected to an infusion pump. This embodiment is applicable to two kinds of proportioning modes of dispensing:

[0044]1. The proportioning method suitable for multi-step dispensing: extract the raw material liquid in the four liquid inlets 21 respectively through an infusion pump, and realize the feeding of the raw material liquid in each liquid inlet 21 by turning on and off the solenoid valve 3 For liquid conditions and liquid intake time, several raw material liquids are mixed and configured first, and then the raw material liquids in the four liquid inlets 21 are respectively extracted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com