Multilateral glue rolling device

A rubber-rolling and multilateral technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of large glue consumption, increased operating costs, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

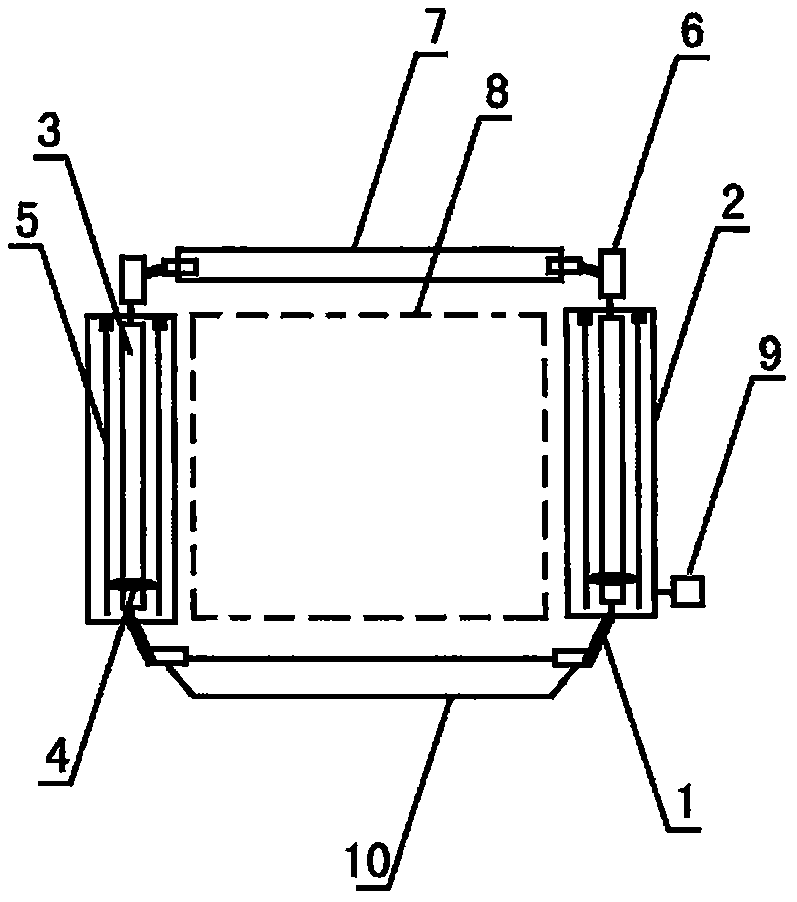

[0012] Embodiment: as shown in the accompanying drawing. A multilateral rubber rolling device, comprising a rubber rolling machine body (1), two vertical rubber rolling parts of equal structure are arranged on the surface of the body (1), including a glue liquid device (2), a glue stick (3) , the return wheel device (4), the suspension structure (5), are connected with the horizontal rubber rolling device (7) through the lifting bracket (6), and the conveying platform (8) is set in the middle. According to the requirements of the glue range, adjust the corresponding parts to perform single-sided or flat-laying operations.

[0013] The utility model relates to a multilateral rubber rolling device. A prompting device (9) is provided on the outside of a body (1), and the prompting information is displayed by sound or LED lights.

[0014] A multilateral glue rolling device, in which a glue solution device (2) is provided with an induction module, which sends out a corresponding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com