A cable well structure

A cable well and cable well cover technology, which is applied in underwater structures, infrastructure engineering, construction, etc., can solve problems affecting the safe operation of cables, loss of cable well covers, water accumulation in cable wells, etc., achieve good anti-theft function and avoid being caught The effect of stealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

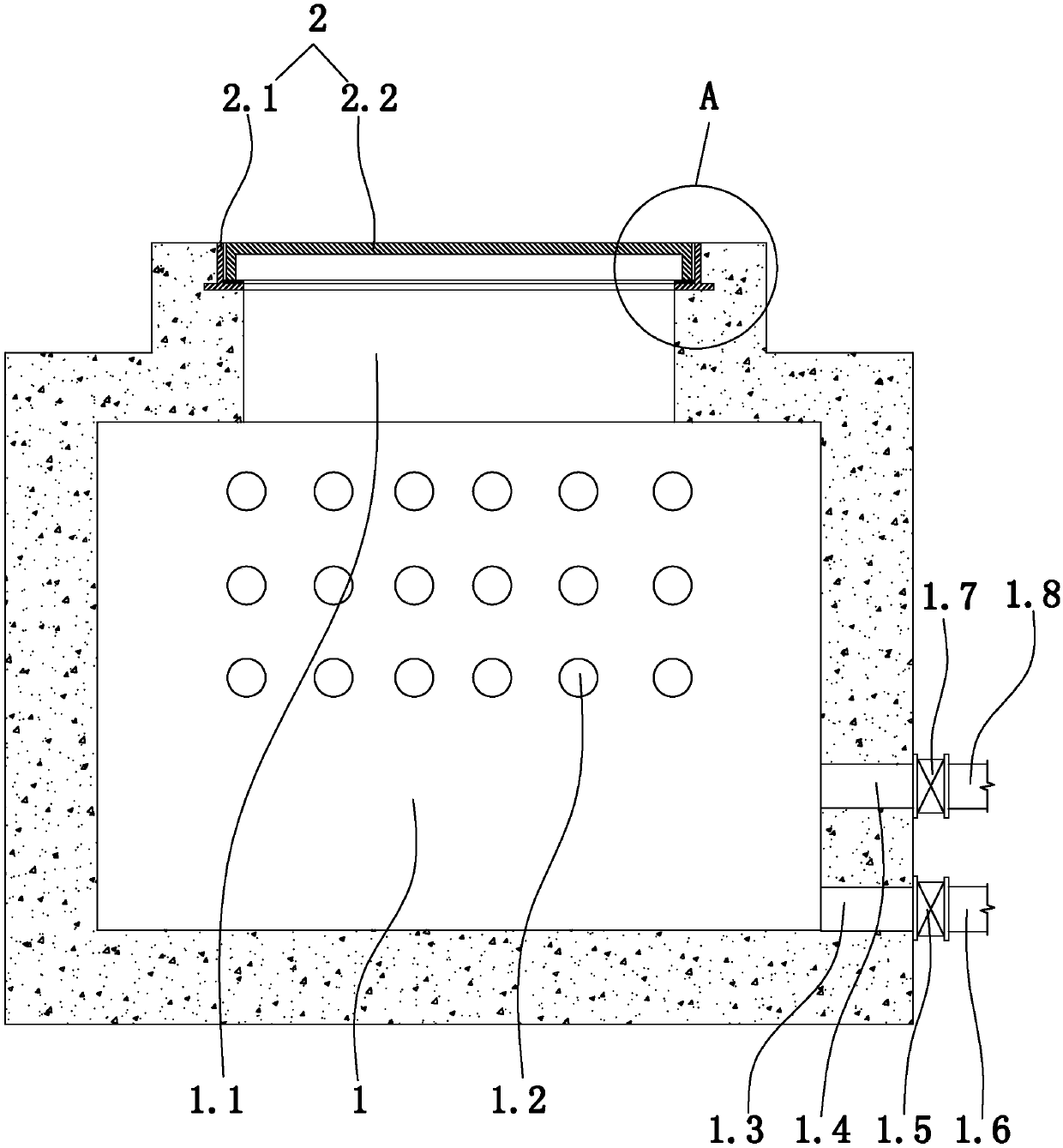

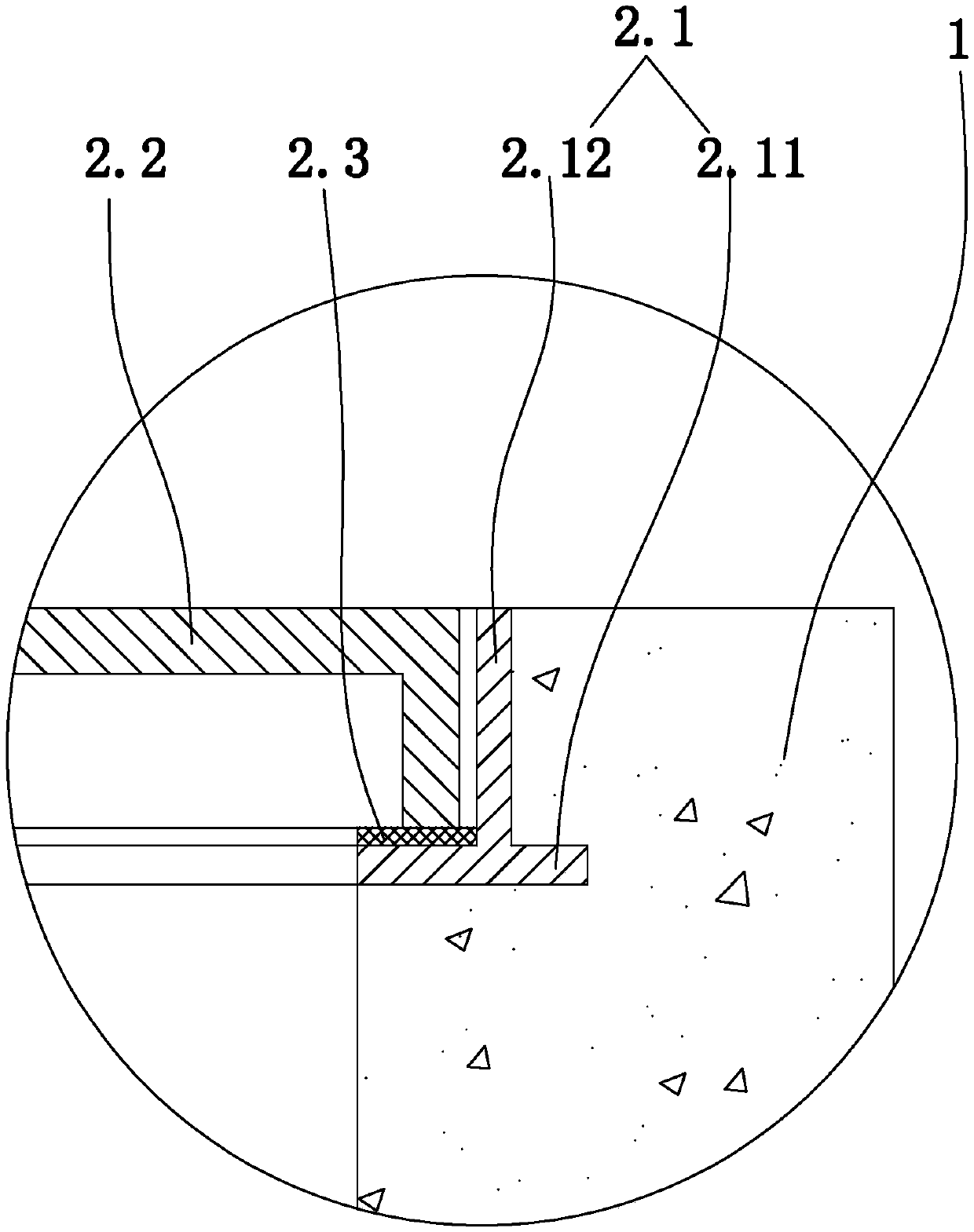

[0032] Embodiment 1: as figure 1 , figure 2 As shown, a cable shaft structure includes a shaft 1 arranged on the road surface and a cable shaft cover device 2 arranged on the wellhead 1.1 of the shaft for sealing the wellhead. The cable well cover device includes a seat ring 2.1 and a well cover 2.2. The seat ring is buried in the wellhead of the shaft. The seat ring includes an annular seat plate 2.11 and a vertical limit sleeve 2.12 arranged on the upper surface of the annular seat plate. The vertical limit sleeve is a circular sleeve. An annular sealing gasket 2.3 is arranged on the upper surface of the annular seat plate and is located in the vertical limiting sleeve. The manhole cover is round. The well cover is arranged in the vertical stop sleeve, and the lower surface of the well cover is close to the annular sealing gasket.

[0033] The side wall of the shaft is provided with a plurality of cable passage holes 1.2 which run through the inner and outer sides of ...

Embodiment 2

[0035] Embodiment 2, the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

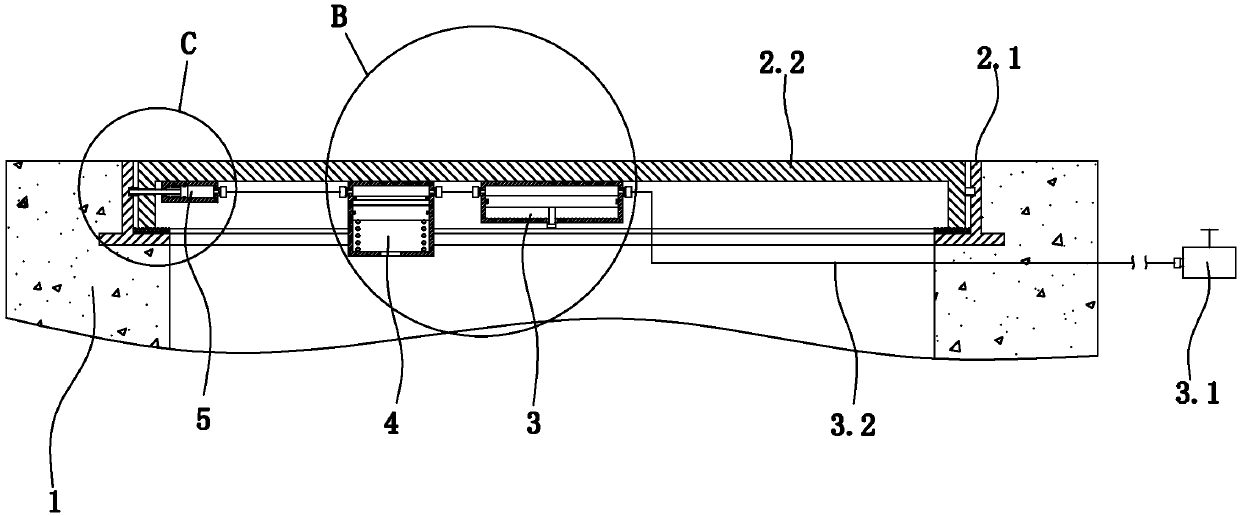

[0036] Such as image 3 As shown, a cable shaft structure also includes a trigger actuator 3 , a flexible buffer device 4 and three anti-theft locking devices 5 . The lower surface of the well cover is provided with a well cover groove 2.21, and the cross section of the well cover groove is circular.

[0037] Such as image 3 , Figure 4 As shown, the triggering actuator includes a switch valve 3.1, a vertical actuator cylinder 3.3 arranged on the bottom surface of the well cover groove, an actuator piston 3.4 slidingly arranged in the vertical actuator cylinder, and an actuator piston 3.4 arranged on the outer side of the vertical actuator cylinder. The first actuator cylinder interface 3.7 and the second actuator cylinder interface 3.8 on the top, the trigger rod through hole arranged on the lower end surface of the vertical actuator cylinder and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com