Linear reciprocating motion mechanism

A technology of linear reciprocating motion and motion platform, which is applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems that the stability is easily affected by the power output parts, the design is complicated, and the cost is high, so as to achieve simple structure, low cost, motion smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

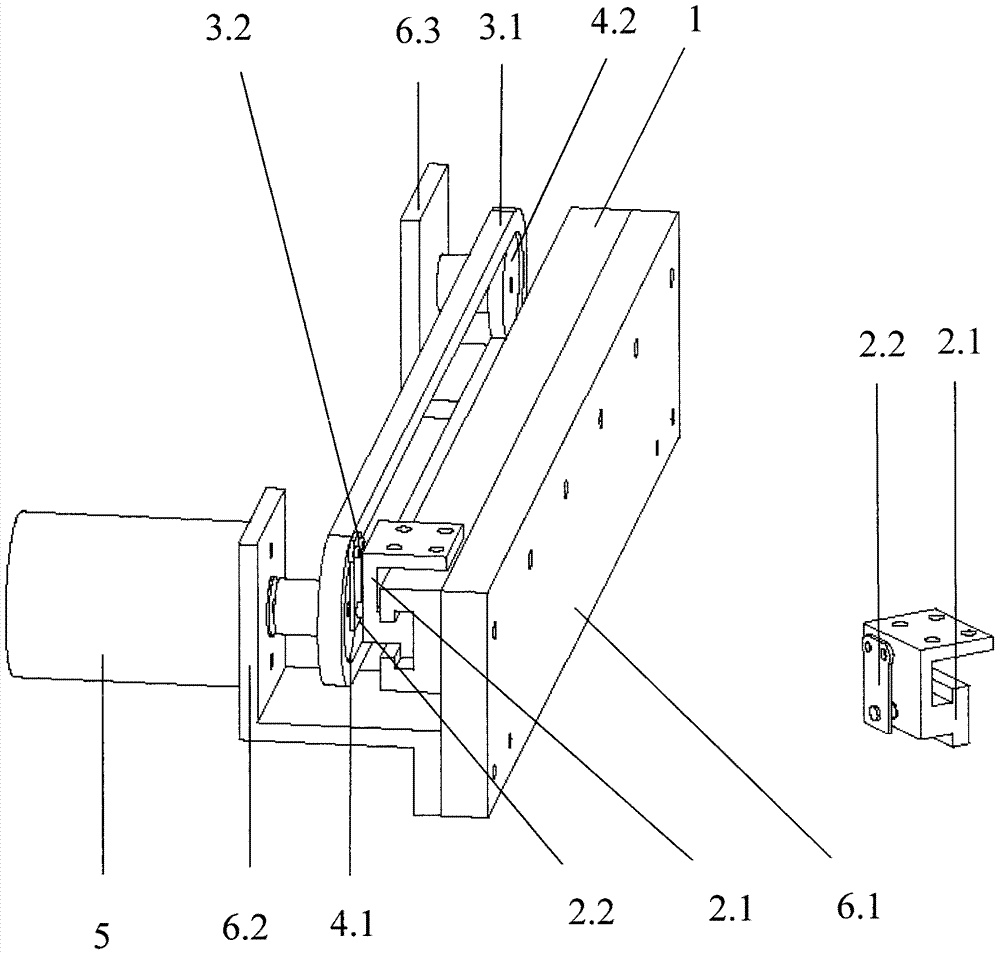

[0011] A linear reciprocating mechanism as shown in the figure includes a concave groove rail, a moving platform, a universal connection device, a chain, a chain fixing point, a motor gear, a shaft gear, a motor, and a fixing device. The chain is provided with a fixing point. The point is connected with the force direction connecting device on the moving platform. The T surface of the moving platform is built in the concave groove rail. The rotation of the motor gear drives the displacement of the fixed point on the chain, and drives the moving platform to move in the concave groove through the universal connecting device. The farthest end between the two gears changes direction into linear reciprocating motion.

[0012] The above is only a preferred implementation of the present invention, and is not intended to limit the present invention in any form. Any modifications, equivalent replacements and improvements made within the technical theory of the present invention should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com